Method for determining content of residual lithium carbonate and lithium hydroxide on surface of positive electrode material

A positive electrode material, lithium hydroxide technology, applied in the direction of analyzing the material by chemical reaction, material analysis by observing the influence on the chemical indicator, and chemical analysis by titration method, which can solve the problem of large errors and poor test results. Problems such as long cycle time and complex components can achieve the effect of reducing errors and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

[0023] A method for measuring residual lithium carbonate and lithium hydroxide content on the surface of positive electrode material, the steps are as follows:

[0024] Step 1: Accurately weigh 30g of sample with a 0.1g precision electronic scale into a 250ml Erlenmeyer flask (accurate to 0.1g), then weigh in 100g of deionized water (accurate to 0.1g), add a magnetic stirrer, and add a rubber stopper 1. Ventilate nitrogen for 2 minutes to discharge the air in the bottle, stir on a magnetic stirrer at low speed for 15 minutes, filter with suction, and use the filtrate for later use.

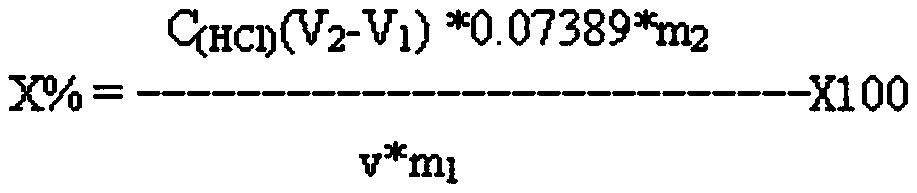

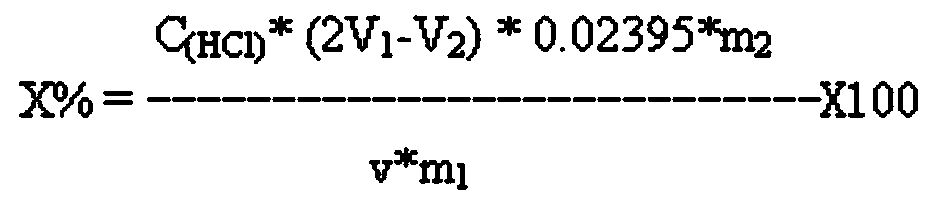

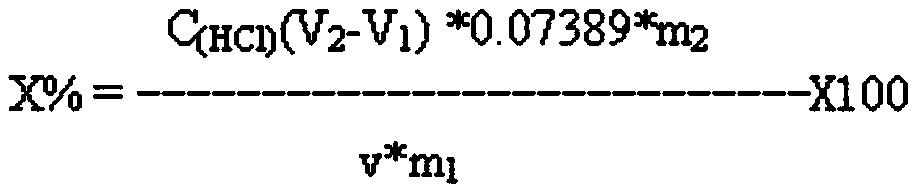

[0025] Step 2: Use a pipette to accurately pipette 10ml of filtrate and place it in a 250ml conical flask, add 1 drop of 0.1% phenolphthalein indicator, the color of the solution is pink at this time, titrate with 0.01mol / L hydrochloric acid standard solution until the pink color is completely Become co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com