Test method for low-temperature thermal conductivity of fluid

A test method and thermal conductivity technology, applied in the field of low temperature thermal conductivity testing of fluids, can solve problems such as the limitation of test accuracy, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

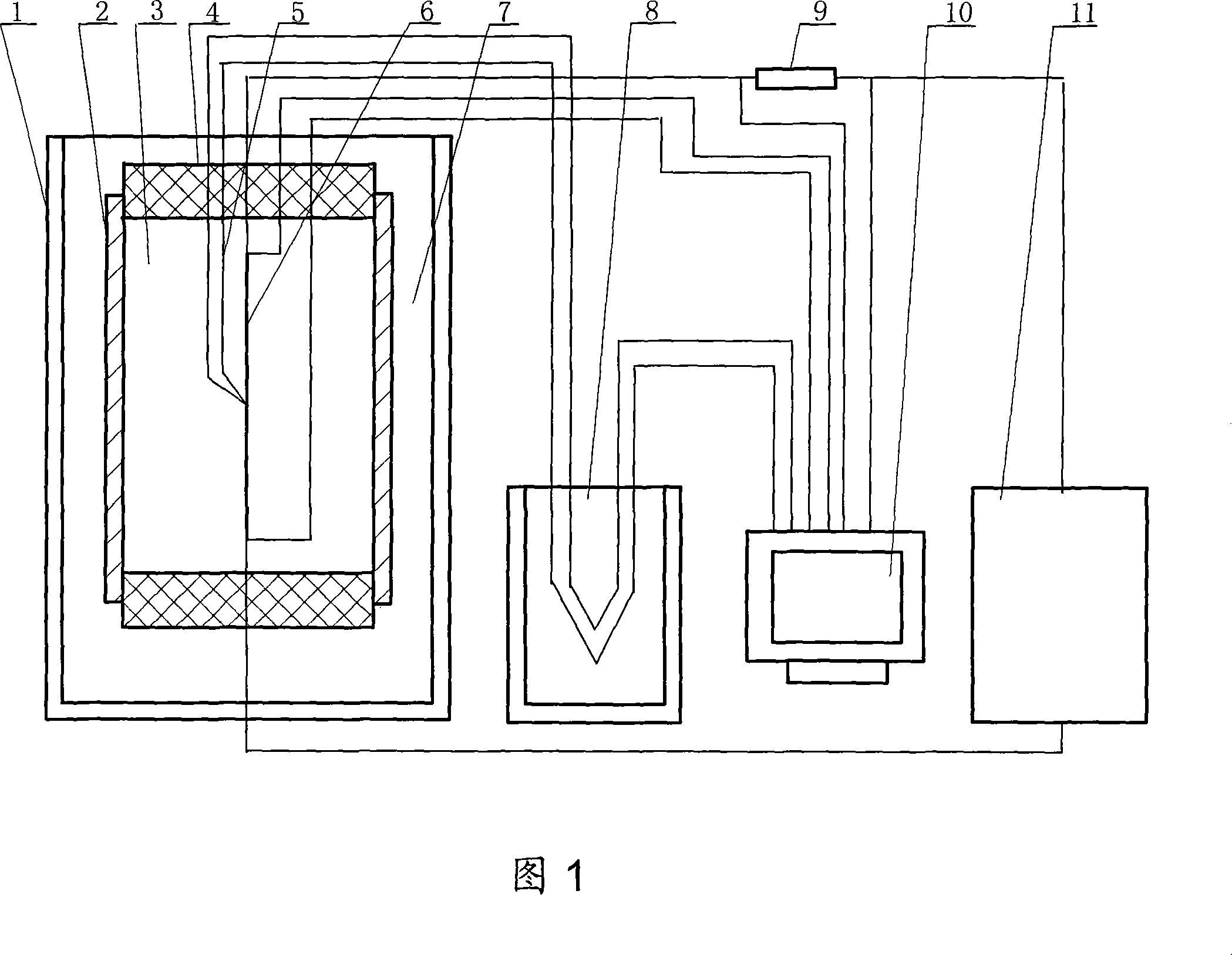

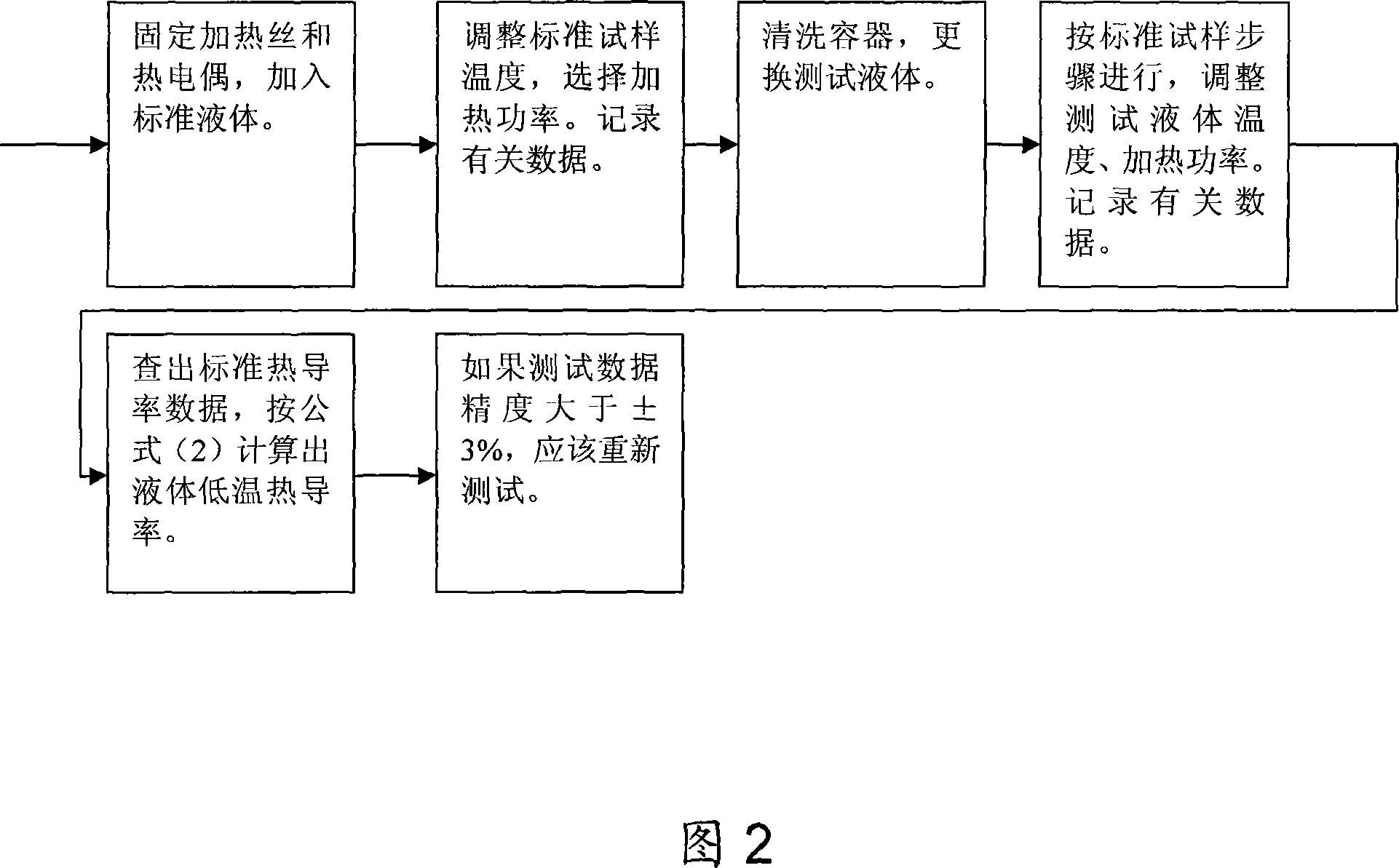

[0040] (1) Fix the temperature measuring thermocouple 5 at the center of the hot wire heater 6, penetrate into the sample container 2 with a diameter of about 20 mm and a length of about 150 mm, and then add the standard sample absolute ethanol to the sample The container 2 is then sealed with a rubber stopper 4 and put into the low temperature and constant temperature container 1 .

[0041] (2) Add low-temperature refrigerant 7 and set the freezing point thermostat 8 so that the temperature reaches the low temperature to be measured. After the temperature is stable, turn on the heating system composed of the standard resistor 9, the data acquisition system 10, the adjustable DC power supply 11, etc., and adjust and select the appropriate heating power. Generally, the heating voltage is about 5V, the current is about 1A, and the heating time is about 3s. At this time, the maximum temperature rise is about 3°C. Record the heating parameters and temperature rise at this time. ...

Embodiment 2

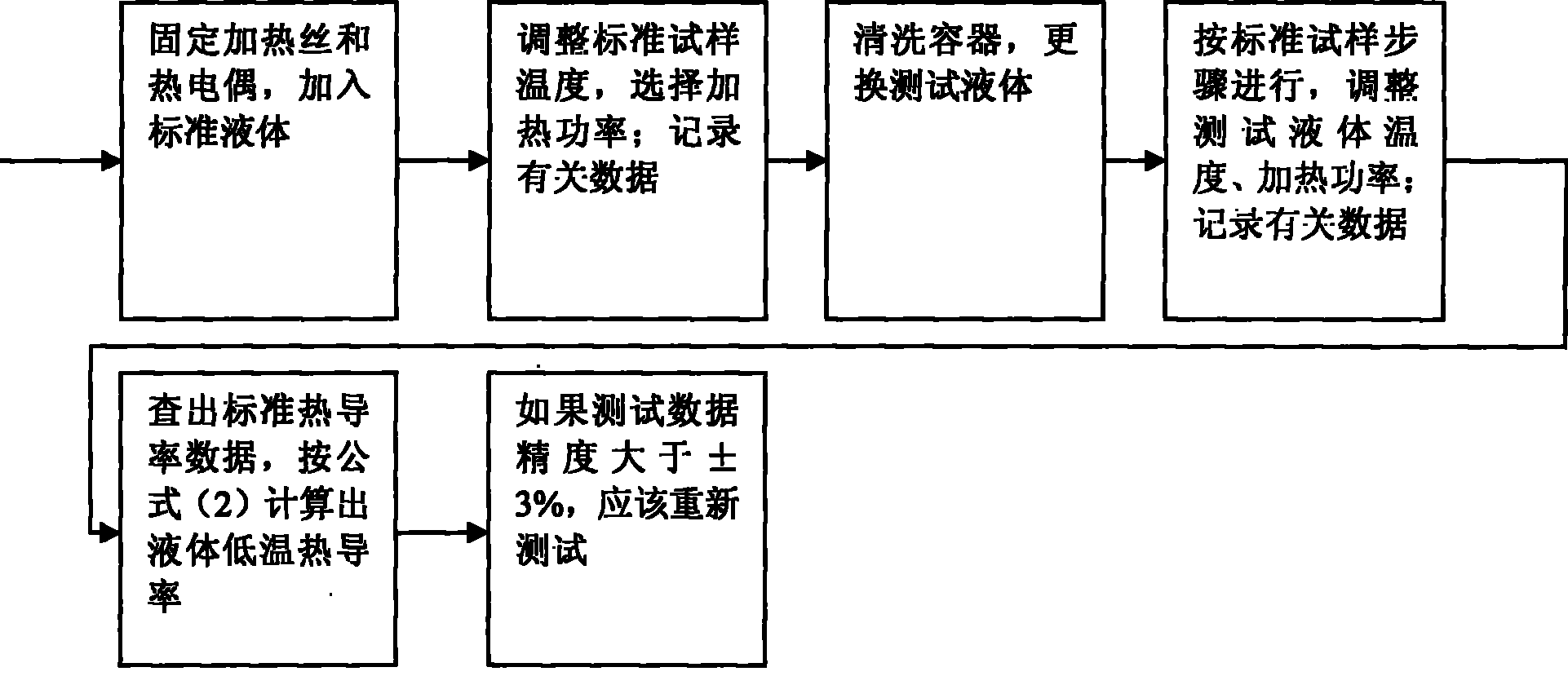

[0046] (1) Carry out by (1) of embodiment 1.

[0047] (2) Pour out the standard sample absolute ethanol, clean and dry it with a cleaning agent, add the second standard liquid ethylene glycol into the sample container 2 and seal it with a rubber stopper 4, repeat the above steps, adjust To the same low temperature and heating parameters, record the temperature rise at this time.

[0048] (3) Find out the corresponding low temperature thermal conductivity data from the average low temperature of the standard sample during the absolute ethanol test (when the standard data between the two intervals is lacking, two standard data points with an interval of no more than 15°C can be used, Linear interpolation fit out), according to the temperature rise of standard sample ethanol and standard sample ethylene glycol, calculate the low-temperature thermal conductivity of ethylene glycol liquid by formula (1).

[0049] (4) According to the comparison between the measured low-temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com