Sieving flow rate measuring method of lithium ion battery sizing agent

A lithium-ion battery and measurement method technology, which is applied in the field of measurement of the sieving flow rate of lithium-ion battery slurry, can solve the problems of low power of the delivery pump, difficulty in sieving, and uneven dispersion of slurry, so as to prevent network blockage and improve the flow rate. The effect of sieve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

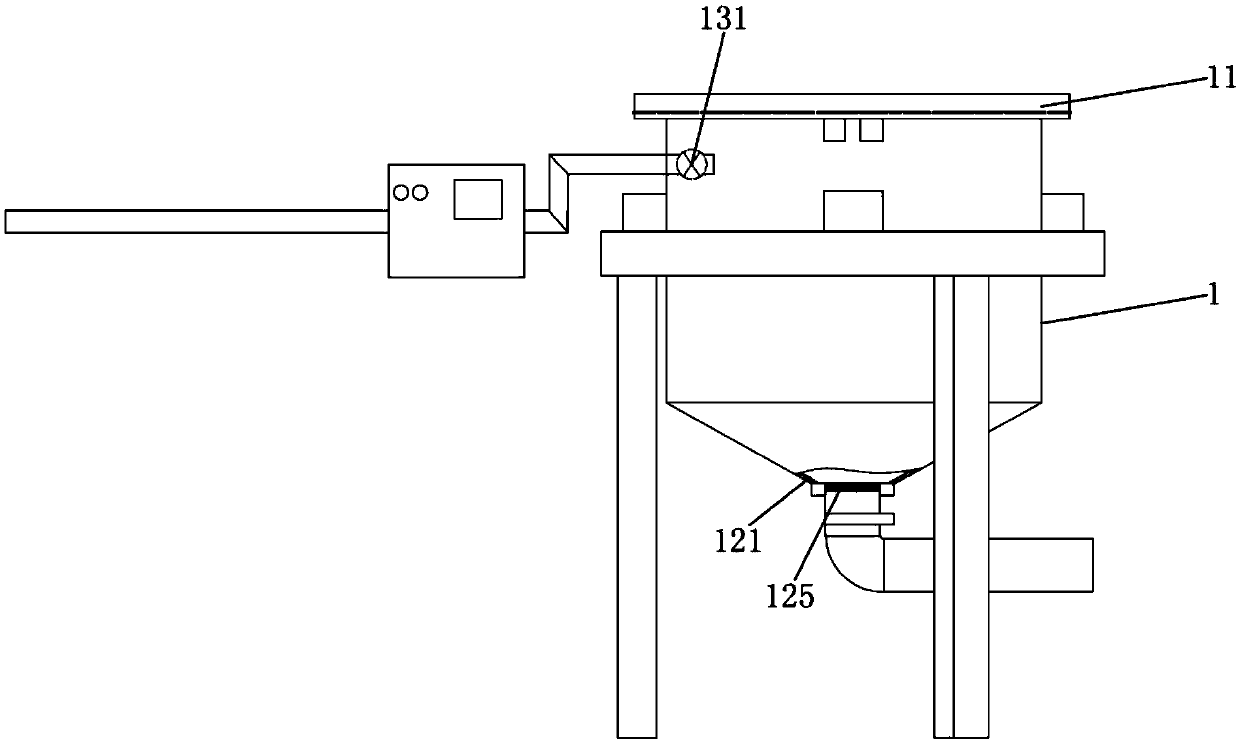

[0023] refer to figure 1 , a method for measuring the sieving flow rate of lithium ion battery slurry provided in the first embodiment includes the following steps:

[0024] 1) Close the discharge valve 125 of the slurry storage tank 1, cover the feed cover 11 of the slurry storage tank 1, open the air valve of the slurry storage tank 1, and let the stabilized gas into the slurry storage tank 1, then Close the air valve 131, then open the discharge valve 125 to release air, then close the discharge valve 125, and then open the feed cover 11;

[0025] 2) Pour the slurry prepared in the homogenization process into the slurry storage tank 1, cover the feeding cover 11, install the screen 124 at the outlet 121 of the slurry storage tank 1, and close the outlet 121 ;

[0026] 3) Simulate the feeding air pressure of the coating machine, open the air valve 131 and continue to feed the stabilized gas into the slurry storage tank 1. After the air pressure reaches the set value and re...

Embodiment 2

[0032] refer to figure 1 , the figure shows a method for measuring the sieving flow rate of a lithium-ion battery slurry provided by the second embodiment of the present invention, and the following improvements have been made on the basis of the above-mentioned first embodiment: the slurry in step 4) is obtained. After the flow rate, the outflowing slurry is poured into the slurry storage tank 1, the screen 124 with a larger mesh is replaced, the flow rate of the slurry is obtained according to the steps, and the change of the flow rate under the screens 124 with different meshes is compared; specifically, The mesh number of the sieve mesh 124 is in the range of 80-200 mesh, and the tests are carried out in order from small to large. Through the above improvements, accurate judgment of the flow rate can be achieved.

Embodiment 3

[0034] refer to figure 1 , the figure shows a method for measuring the sieving flow rate of a lithium-ion battery slurry provided in the third embodiment of the present invention, and the following improvements have been made on the basis of the above-mentioned first embodiment: After the pressurized gas is introduced into the storage tank 1, the air tightness test of the slurry storage tank 1 is also carried out; in step 3), the air pressure of the slurry storage tank 1 is less than 1MPa; in step 3), the setting of the discharge time The value is 30-120 seconds. Through the above improvement, the accurate judgment of the flow velocity can be further realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com