Hard carbon negative electrode slurry and preparation method thereof

A negative electrode slurry and hard carbon technology, which is applied to battery electrodes, electrical components, circuits, etc., can solve the problems of difficult dispersion, small particle size of hard carbon materials, and poor dispersion ability, and achieve high solid content and good stability of the slurry performance, the effect of good sieving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

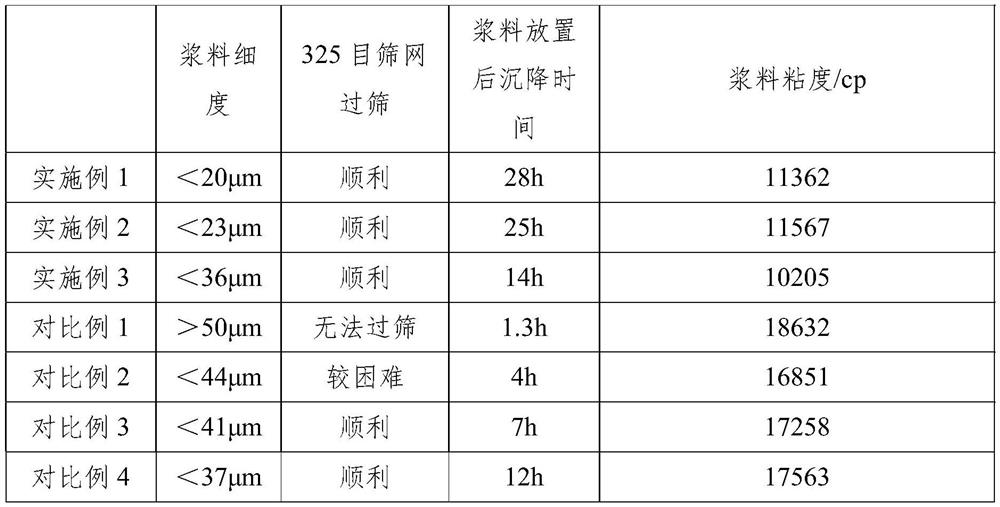

Examples

Embodiment 1

[0051] This embodiment provides a hard carbon negative electrode slurry, the raw material of which is composed of solid powder and a dispersion medium; wherein,

[0052] The solid powder includes the following components by weight: 95 parts of hard carbon material, 2 parts of conductive agent, 1 part of composite dispersant, and 2 parts of SBR;

[0053] The composite dispersant is composed of sodium polyepoxysuccinate and sodium carboxymethyl cellulose with a mass ratio of 1:1; the conductive agent is acetylene black;

[0054] The dispersion medium is water; in terms of mass ratio, water:total mass of solid powder=0.9:1.

[0055] The present embodiment also provides a method for preparing the above-mentioned hard carbon negative electrode slurry, comprising the following steps:

[0056] (1) adding water to 500L double paddle double dispersion equipment;

[0057](2) adding composite dispersant to water, and mixing 90min under the stirring speed of 35r / min, the dispersing disc...

Embodiment 2

[0063] This embodiment provides a hard carbon negative electrode slurry, the raw material of which is composed of solid powder and a dispersion medium; wherein,

[0064] The solid powder includes the following components by weight: 95 parts of hard carbon material, 2 parts of conductive agent, 1 part of composite dispersant, and 2 parts of SBR;

[0065] The composite dispersant is composed of polyvinylpyrrolidone and sodium carboxymethyl cellulose with a mass ratio of 1:1; the conductive agent is acetylene black;

[0066] The dispersion medium is water; in terms of mass ratio, water:total mass of solid powder=0.9:1.

[0067] This embodiment also provides a method for preparing the above-mentioned hard carbon negative electrode slurry, comprising the following steps:

[0068] (1) Add water to 500L double paddle double dispersion equipment;

[0069] (2) adding composite dispersant to water, and mixing 90min under the stirring speed of 35r / min, the dispersing disc linear speed ...

Embodiment 3

[0075] This embodiment provides a hard carbon negative electrode slurry, the raw material of which is composed of solid powder and a dispersion medium; wherein,

[0076] The solid powder includes the following components by weight: 95 parts of hard carbon material, 2 parts of conductive agent, 1 part of composite dispersant, and 2 parts of SBR;

[0077] The composite dispersant is composed of sodium polyepoxysuccinate and polyvinylpyrrolidone with a mass ratio of 1:1; the conductive agent is acetylene black;

[0078] The dispersion medium is water; in terms of mass ratio, water:total mass of solid powder=0.9:1.

[0079] This embodiment also provides a method for preparing the above-mentioned hard carbon negative electrode slurry, comprising the following steps:

[0080] (1) Add water to 500L double paddle double dispersion equipment;

[0081] (2) adding composite dispersant to water, and mixing 90min under the stirring speed of 35r / min, the dispersing disc linear speed of 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com