A sintering ratio calculation and sinter cost optimization method

A cost-optimized, sintered ore technology, applied in the field of smelting, can solve problems such as the difficulty of accurate quantification of sintering manufacturability, large fluctuations in sintered ore quality, and misleading production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

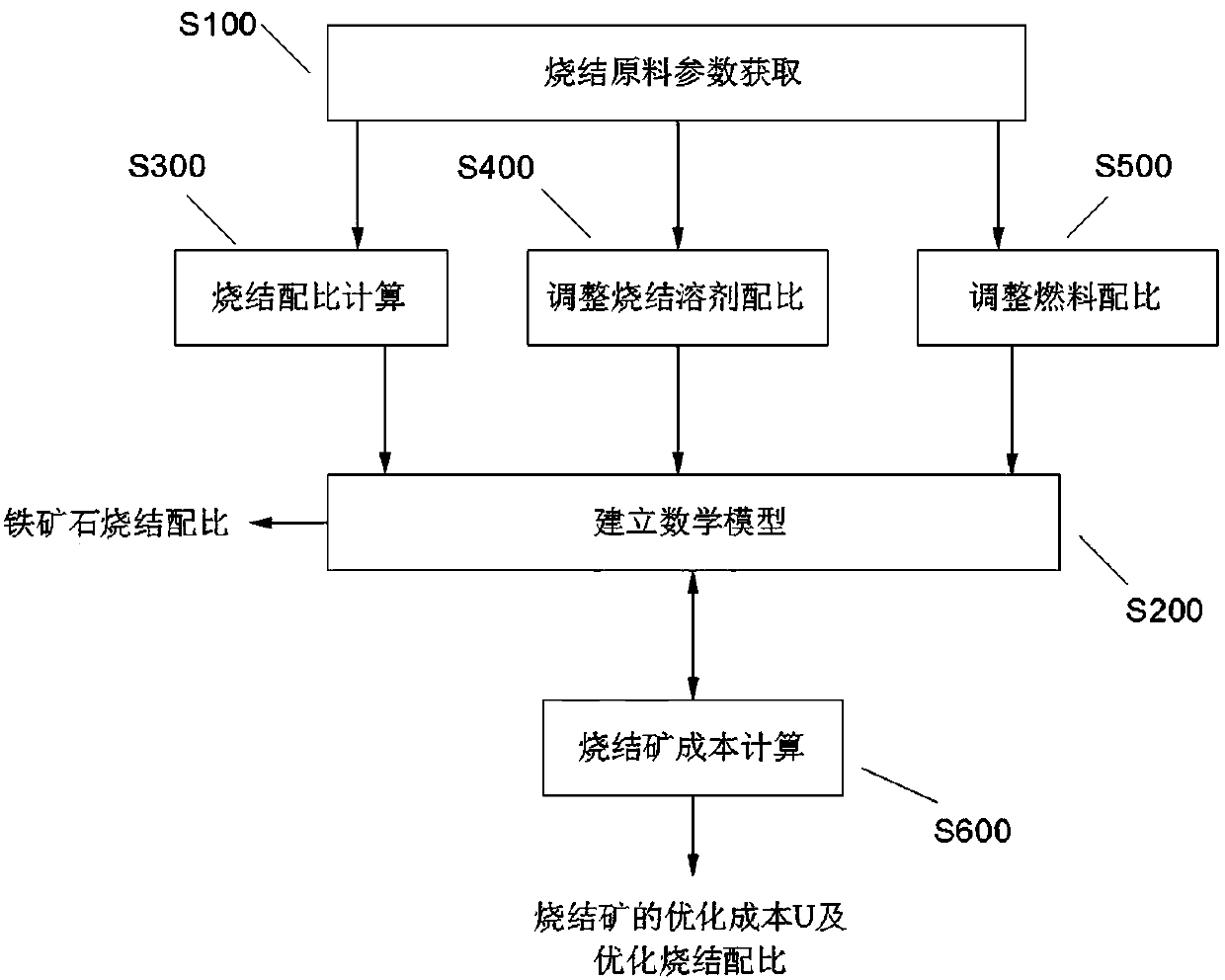

Method used

Image

Examples

Embodiment 1

[0038] S100: According to the relationship between sintering raw materials and sintering ore ratio, with cost as the optimization target, establish a linear programming model and bring it into an Excel table. The linear programming model includes:

[0039] Decision variable: X i =(x 1 , x 2 , x 3 ..., x n ),

[0040] Objective function: ,

[0041] Restrictions: g j (X) ≤1 (j=1,2,...m,m),

[0042] where: X i ∈R,X i is the amount of the i-th raw material; R is the basicity base number specified by the sinter, that is, the content of CaO and SiO in the composition of the sinter 2 Content ratio; i is a natural number, i=1, 2, 3,..., n, n is the type of sintering raw material; minf(X i ) = cost of the i-th raw material in the sinter ore; j is a natural number, j=1, 2, ... m, m is the number of constraints;

[0043] In this embodiment, since the raw material is a wet material, the wet unit consumption of the raw material is used as a decision variable, and the dry ...

Embodiment 2

[0059] S100-S500 are the same as in Embodiment 1.

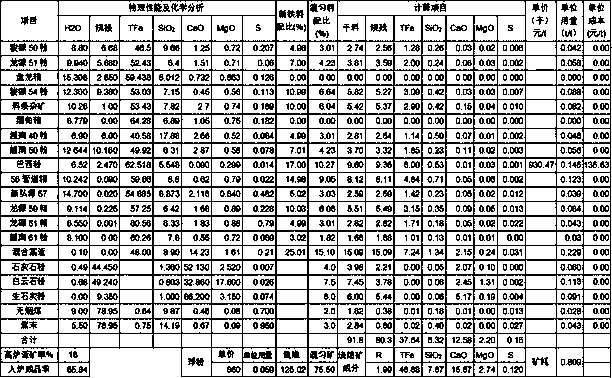

[0060] S600: Adjust the mixing ratio in Table 3 in the Excel table of S100, then the raw material cost U is:

[0061] ,in m i is the unit cost of the i-th raw material;

[0062] Then bring other items of sintered ore into Table 4:

[0063] Table 3 Sintering ratio and cost forecast table

[0064]

[0065] Table 4 Sintering cost forecast table

[0066]

[0067] It can be seen from Table 4 that the calculated value of the unit cost of sintering ore is U=831.188 yuan / t.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com