A device for detecting chip stacking during testing

A technology for detecting chips and laminations, used in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., to improve the efficiency of discovery and processing, and improve the process of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

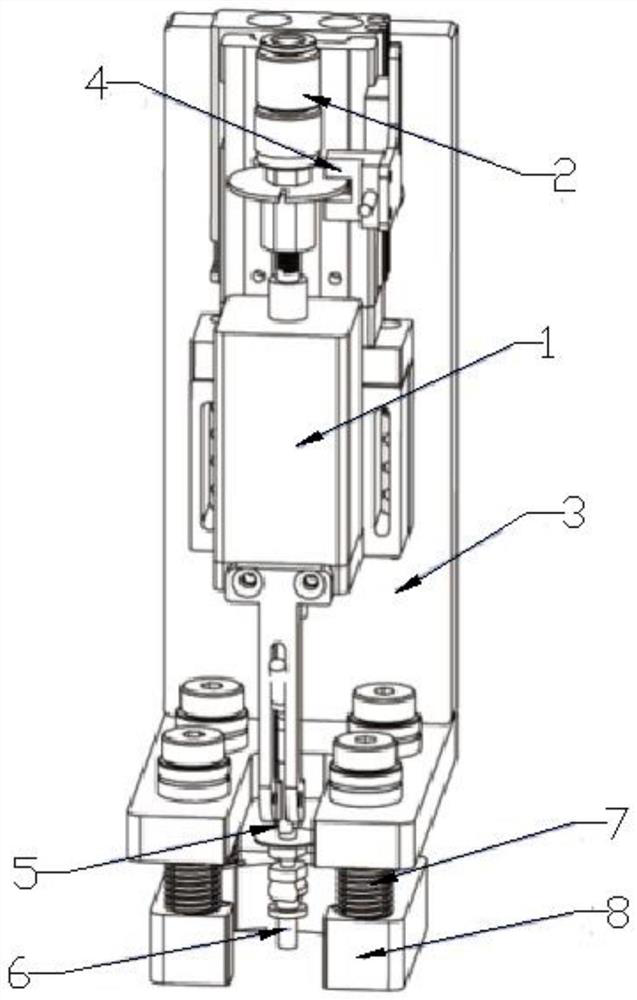

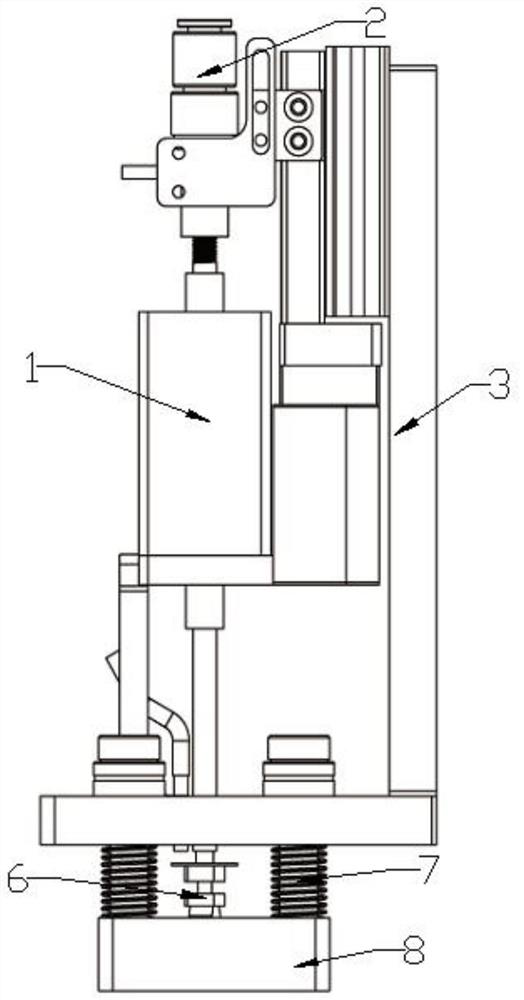

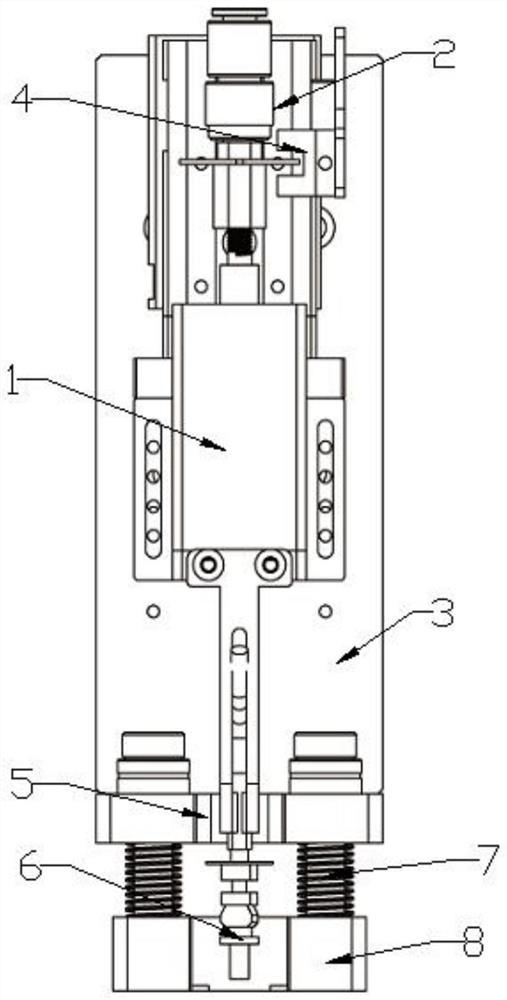

[0021] like Figure 1-4 As shown, a device for detecting chip lamination during testing, including a rotating motor 1, a slide cylinder 2, a main board 3, a rotation sensor 4, a buffer device 6 and a socket pressing block 8, and the slide cylinder 2 is fixed on the main board by bolts 3, the piston end of the sliding table cylinder 2 is connected to the rotating motor 1 through an aluminum block, and is tightened by bolts so that the rotating motor 1 can be driven up and down by the sliding table cylinder 2; the upper cover of the sliding table cylinder 2 is equipped with a rotating The sensor 4 and the buffer device 6 are installed on the output end of the rotary motor 1, and the buffer device 6 is driven to rotate by the rotary motor 1, and the optical fiber sensor 5 is also installed on the aluminum block of the rotary motor 1, and two Socket pressing blocks 8 are symmetrically installed on the main board 3, and insert the pressing spring 7 thereon.

[0022] Induction shee...

Embodiment 2

[0025] like Figure 1-4 As shown, the main board 3 is an L-shaped plate composed of an aluminum fixing plate and an aluminum base plate, the slide cylinder 2 is fixed on the aluminum fixing plate, and the Socket pressing block 8 is fixed on the aluminum base plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com