Fuel cell bipolar plate sealing structure and sealing method

A sealing structure and fuel cell technology, which is applied in the direction of fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of high labor costs and high R&D costs of injection molded silicone sealing rings, saving time and cost and reducing equipment Cost and research and development costs, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

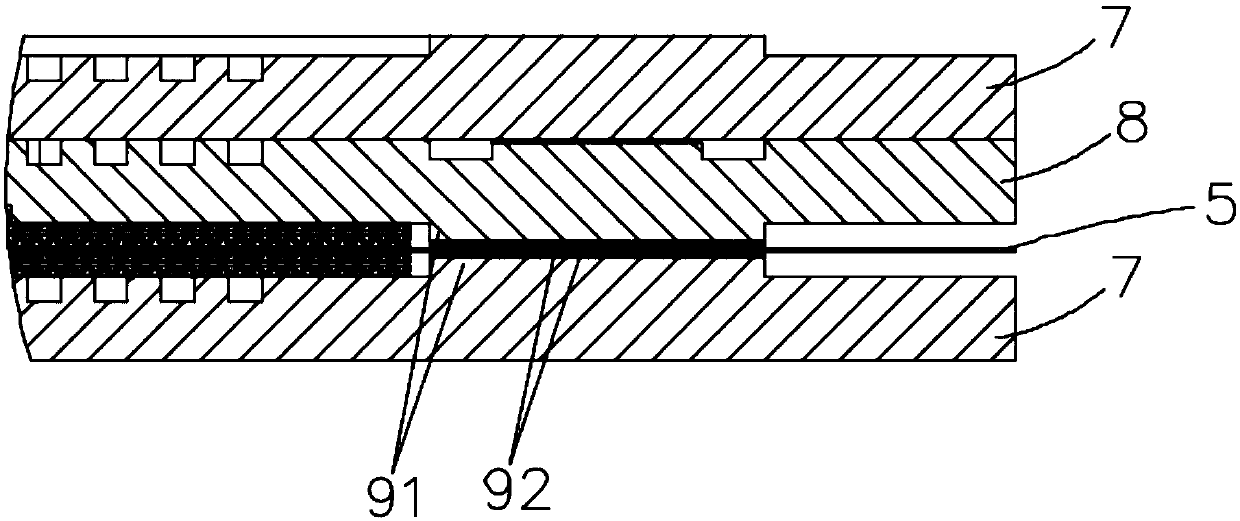

[0024] Such as figure 2 As shown, the fuel cell bipolar plate sealing structure is provided in this embodiment, including two bosses 91 respectively arranged on the corresponding positions of the cathode plate 7 and the anode plate 8 sealing rings, and glue 92 is coated on the two bosses 91, the The glue 92 has a certain thickness after curing, and has elastic deformation.

[0025] The boss 91 has a width of 0-10 mm and a height of 0-5 mm, and its specific design value needs to match the thickness of the MEA frame 5 to ensure sealing after assembly. For example, the original design of the sealing groove size is 4mm in width and 0.3mm in depth, which can be changed to the design of boss 91. The width of boss 91 is 4mm, and the height of boss 91 is 0.1mm. The lower compression rate is 20%, and the thickness of the silk screen adhesive layer is 40 μm.

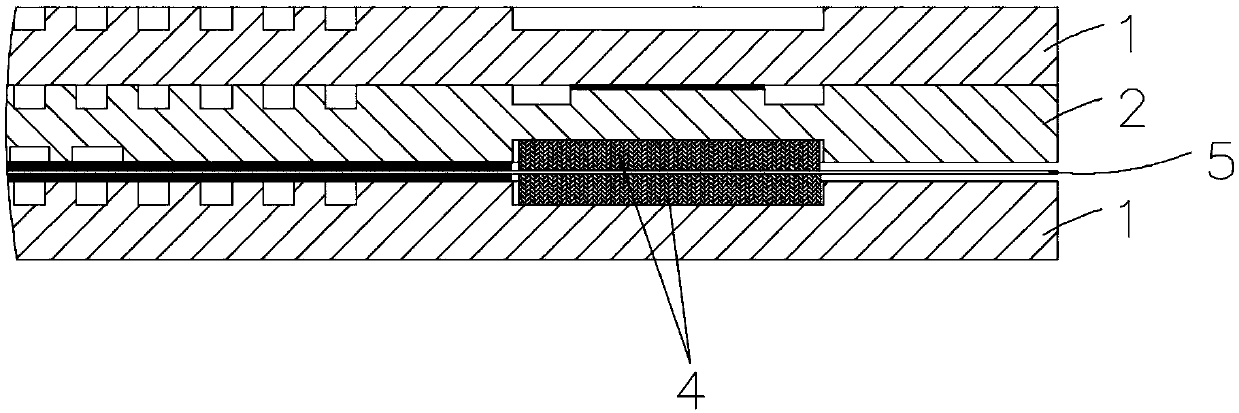

[0026] and Figure 1 Compared with setting grooves and manually inserting the silicone sealing ring 4 in the prior art, the ...

Embodiment 2

[0037] A graphite bipolar plate with a boss 91 structure is processed and formed by an engraving machine. The width of the boss 91 is 4 mm, and the height of the boss 91 is 0.1 mm. The glue 92 used as the seal is made of polyisobutylene (PIB). The specific silk screen printing process parameters are: the mesh number of the screen printing screen is 60 mesh, the working pressure is 0.55MPa, and the number of times of glue application is 1 time. The thickness of the adhesive layer after silk screen printing is calculated to be about 40 μm. After drying at 120°C for 4 hours, the bipolar plate with seals can be obtained directly.

Embodiment 3

[0039] A graphite bipolar plate with a boss 91 structure is formed by stamping, the width of the boss 91 is 3.6 mm, and the height of the boss 91 is 0.1 mm. The glue 92 used as the seal is selected from uniformly mixed two-component liquid silica gel. The specific parameters of the silk screen printing process are: the mesh number of the screen printing screen is 80 mesh, the working pressure is 0.5 MPa, and the number of times of glue application is 2 times. The thickness of the adhesive layer after silk screen printing is calculated to be about 50 μm. After drying at 140°C for 30 minutes, the bipolar plate with the seal can be directly obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com