Light brick batching system

A batching system and lightweight brick technology, applied in mixer accessories, dissolving, mixing machines, etc., can solve problems such as easy blockage, low efficiency, and affecting material delivery efficiency, and achieve the effect of convenient material thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

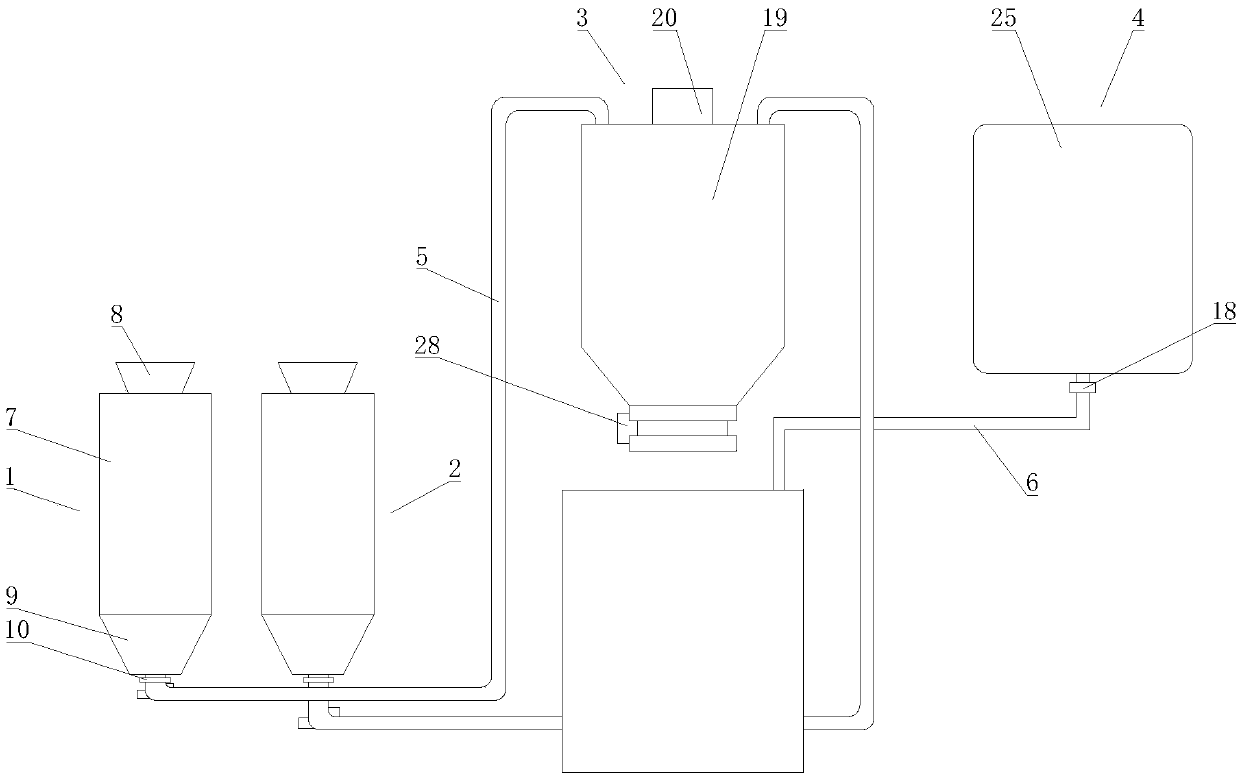

[0021] like Figure 1-3 as shown, figure 1 It is a structural schematic diagram of a lightweight brick batching system proposed by the present invention.

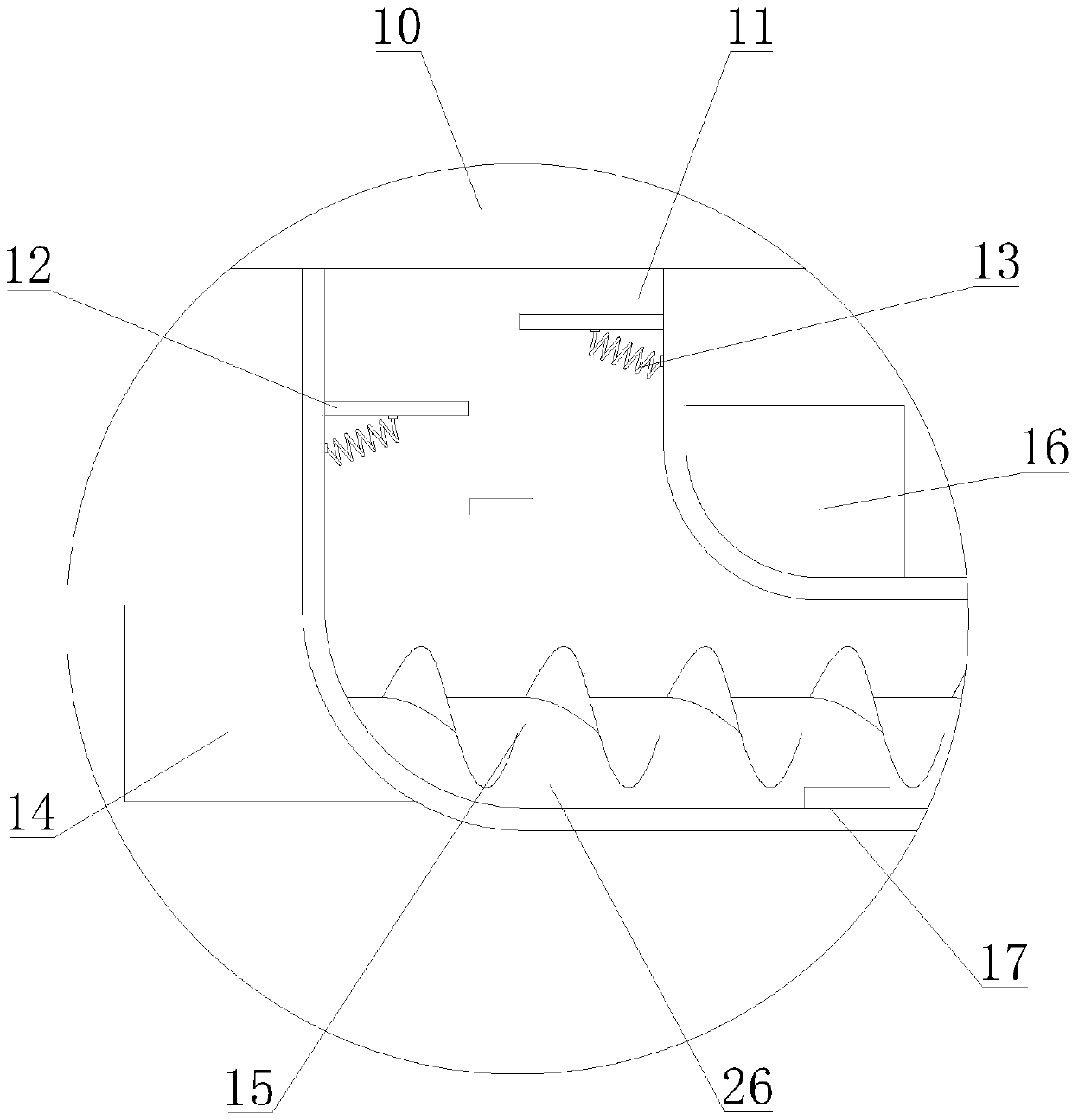

[0022] figure 2 It is a structural schematic diagram of the first dredging member and the second dredging member in a lightweight brick batching system proposed by the present invention.

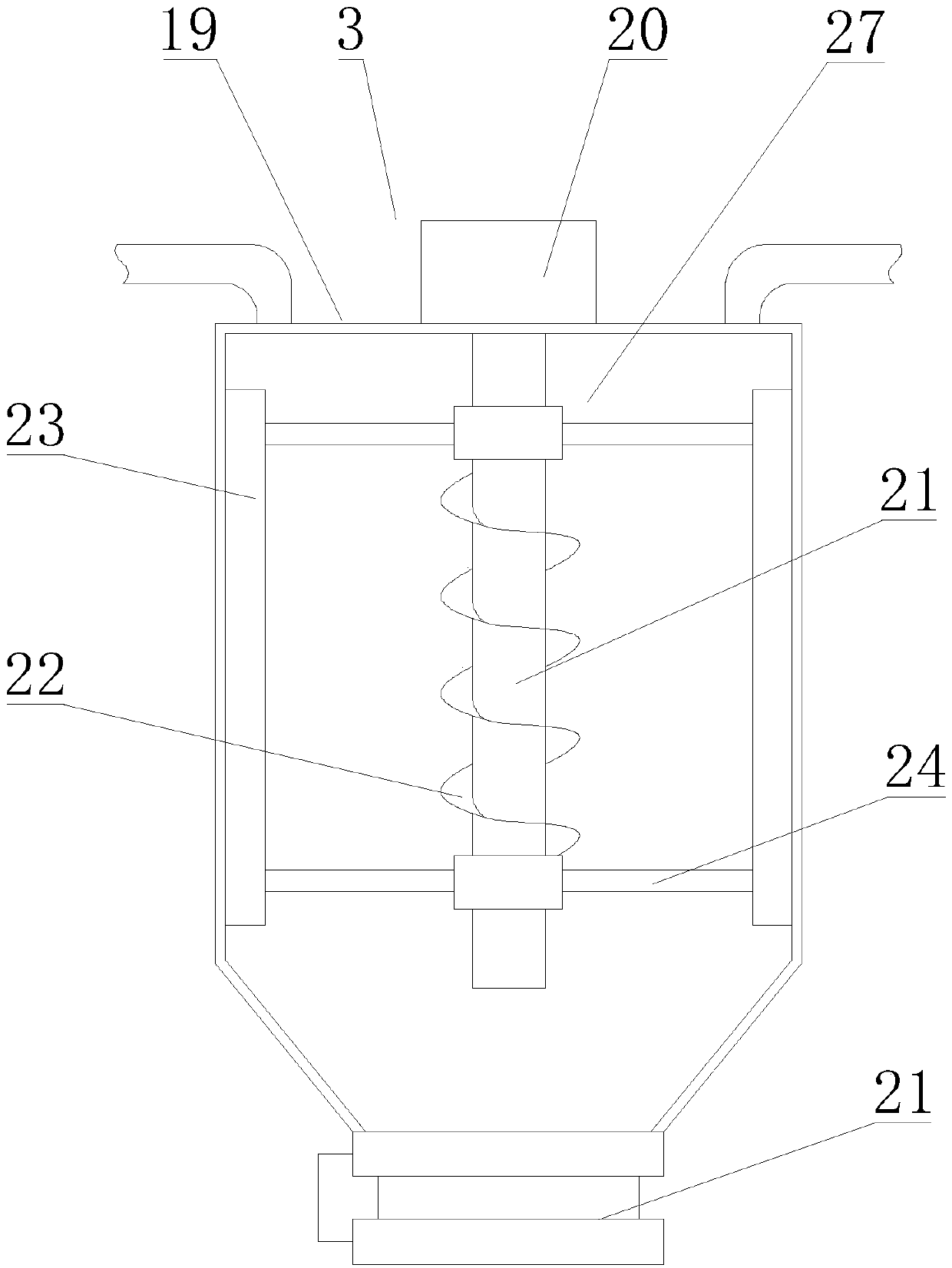

[0023] image 3 It is a structural schematic diagram of the preparatory device in a lightweight brick batching system proposed by the present invention.

[0024] refer to Figure 1-3 , a lightweight brick batching system proposed by the present invention, including a base material storage device 1, an auxiliary material storage device 2, a preparation device 3, a solution storage device 4, a first transmission device 5, a second transmission device 6, and a material guide assembly 11 , the first dredging member 26 and the second dredging member 16; the auxiliary material storage device 2 has the same structure as the base material s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap