Preparation method and application of lamellar UiO-66/g-C3N4/Ag composite material

A composite material, g-c3n4 technology, applied in the field of preparation of layered UiO-66/g-C3N4/Ag composite material, can solve the problem of rapid recombination hindering photocatalytic reaction, and achieve excellent adsorption and photocatalytic effect, stability Good, the effect of material innovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

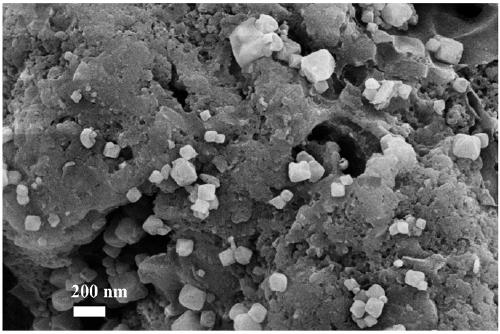

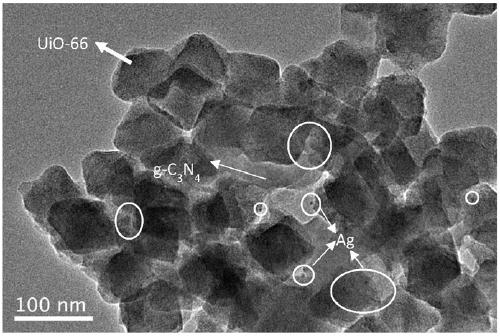

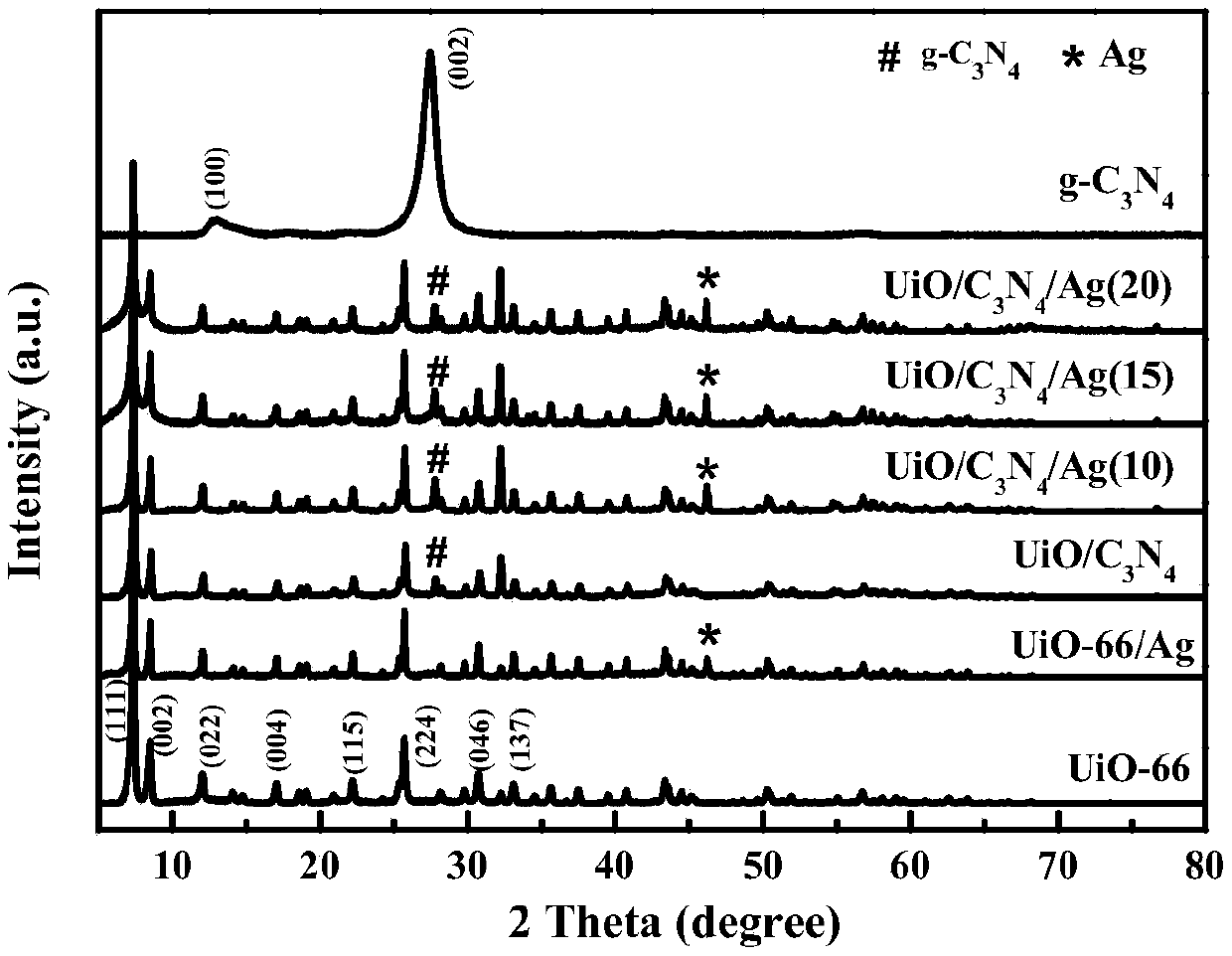

Image

Examples

Embodiment 1

[0027] Protonated g-C 3 N 4 By conventional solvothermal synthesis. Specifically, proceed as follows:

[0028] (1) Disperse 5 g of melamine into 300 ml of HCl solution (2M) and stir for 2 hours, then filter, wash with deionized water and dry at 100° C. to obtain a white powder.

[0029] (2) Place the above white powder evenly in 6 sealed crucibles and calcinate in a tube furnace for 4 hours (550°C, 5°C / min) to obtain a light yellow powder, which is g-C 3 N 4 .

[0030] (3) The protonation process is as follows: 1g of g-C 3 N 4 Ultrasonic dispersion into 60ml of HCl solution (6M), then charged into a 100ml reactor and heated at a temperature of 100°C.

[0031] (4) Then the cooled g-C 3 N 4 The mixture was washed with deionized water until the solution was neutral, and then dried in a vacuum oven at 100 °C to obtain protonated g-C 3 N 4 .

[0032] UiO-66 was also synthesized by solvothermal method. Specifically follow the steps below:

[0033] (1) 0.386g (1.67mmol)...

Embodiment 2

[0045] Adopt the same preparation method as Example 1, change g-C 3 N 4 The amount of solution added, the prepared UiO-66 / g-C 3 N 4 / Ag(10).

Embodiment 3

[0047] Adopt the same preparation method as Example 1, change g-C 3 N 4 The amount of solution added, the prepared UiO-66 / g-C 3 N 4 / Ag(20).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap