Simple leveling worktable used for electric spindle drilling

A technology of electric spindle and workbench, which is applied in the direction of boring/drilling, drilling/drilling equipment, manufacturing tools, etc., to achieve low failure rate, easy processing and installation, and reduce extra workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

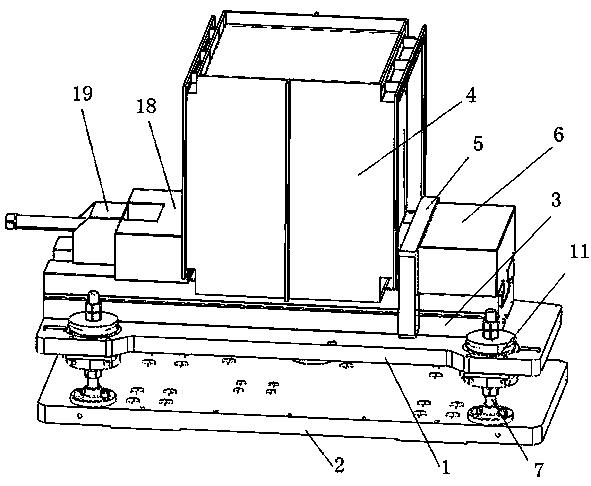

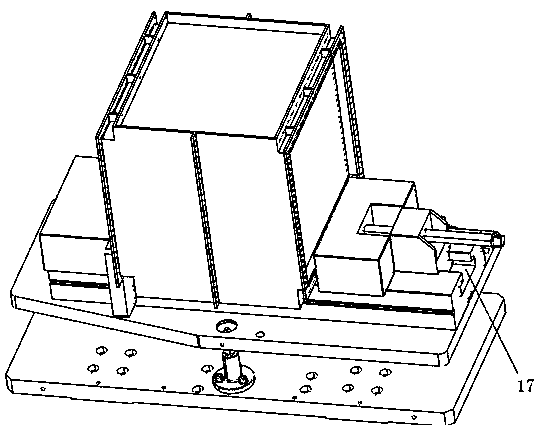

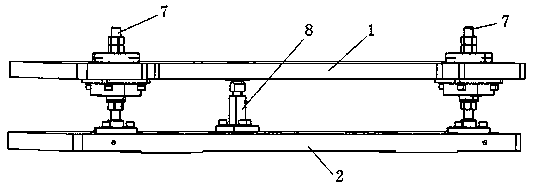

[0020] according to Figure 1-Figure 7 As shown, this embodiment provides a simple leveling workbench for electric spindle drilling, including a leveling plate 1 and a support plate 2, and a base 3 is provided on the upper surface of the leveling plate 1 for installing heat dissipation 4, the radiator 4 is connected with the fixed clamp 6 through the spacer 5, the left and right symmetrical support shaft 7 is provided at one end of the leveling plate 1 and the support plate 2, and the joint bearing support shaft 8 is provided at the middle of the other end, The upper end of the joint bearing support shaft 8 is provided with a joint bearing seat 9 for installing the joint bearing 10 , and the joint bearing seat 9 is connected with the leveling plate 1 . A compression spring 11 is provided on the support shaft 7, a spring upper cover 12 is provided on the support shaft positioned above the leveling plate 1, and a spring lower cover 13 is arranged on the support shaft positioned ...

Embodiment 2

[0022] A small horizontal observation device is installed on the leveling plate to make the adjustment process more convenient. In addition, a power device and a feedback structure are provided under the adjustment nut, so that the user's manual adjustment becomes automatic adjustment, and the data of the feedback structure is transmitted to the system.

[0023] In the present invention, two compression structures and a joint bearing support shaft 8 are arranged in the middle of the leveling plate 1 and the support plate 2 to achieve the supporting effect, wherein the joint bearing support shaft 8 is provided with a rotatable joint bearing 10, which can be operated by The adjustment nut 15 can easily adjust the horizontal position of the leveling plate 1, and the spring lower cover 13 is tightly pressed on the adjustment nut 15 by the compression spring 11 to ensure that there is no movement in the work engineering. The present invention uses the compression spring 11 to make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com