Motor carbon brush grinding tool

A technology for grinding tools and carbon brushes, applied in the direction of manufacturing tools, grinding workpiece supports, grinding machines, etc., can solve the problems of operation risks, grinding carbon brushes, etc., to improve reliability, reduce operation time, and improve operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

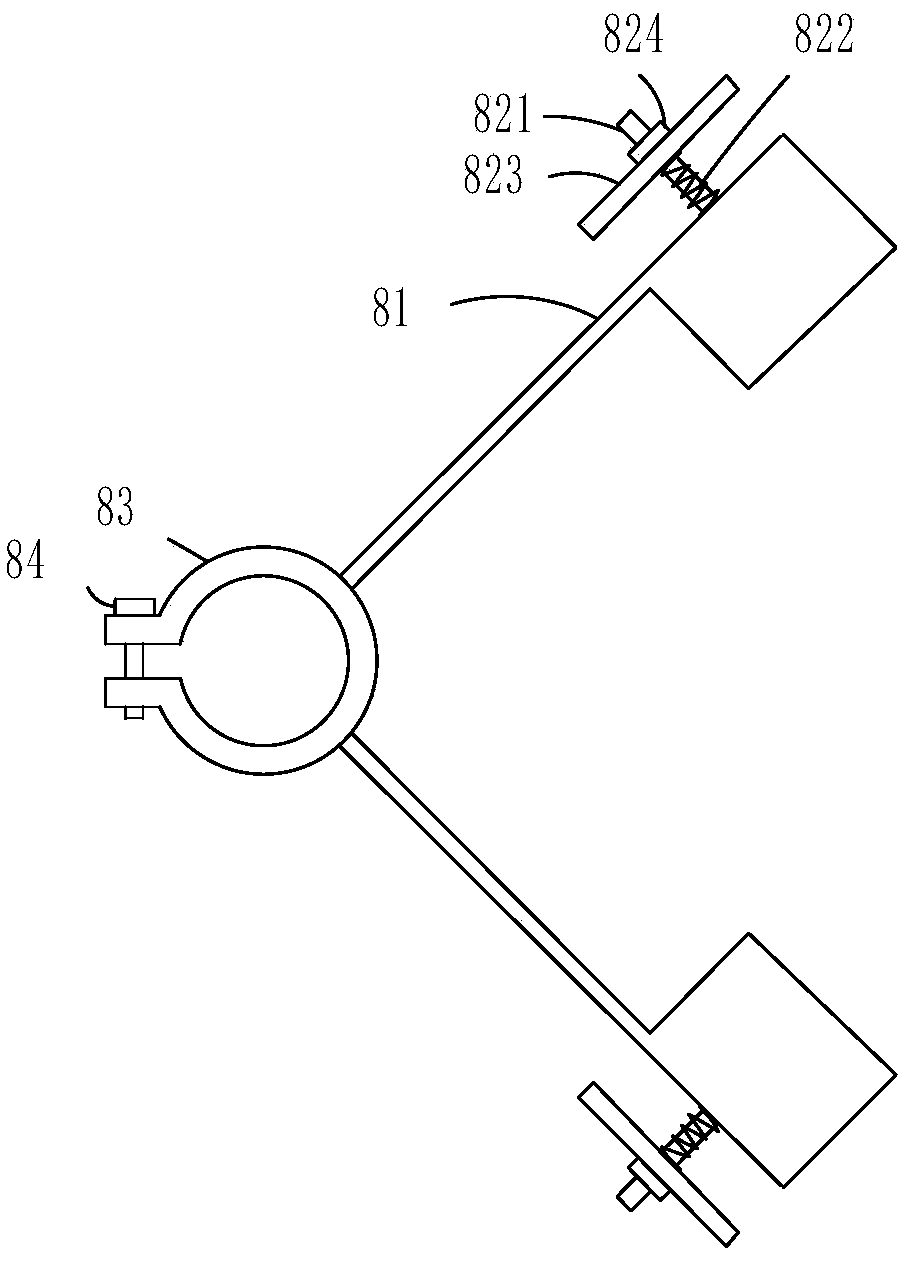

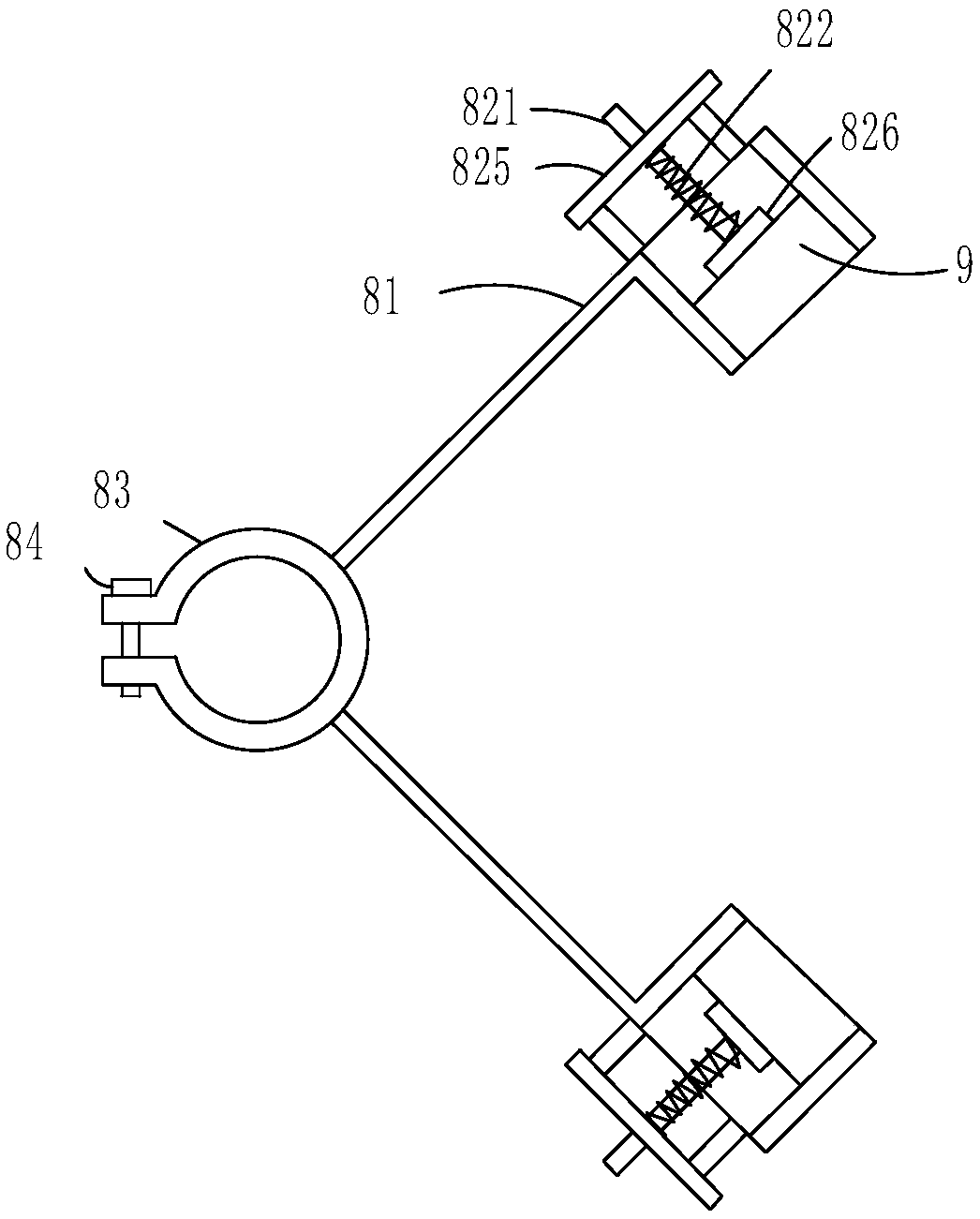

[0040] Further, see figure 2 , as a specific embodiment of the motor carbon brush grinding tool provided by the present invention, the elastic pressing mechanism includes a guide post 821 fixedly connected to the mounting frame 81 and a rotating pressing plate 823 sleeved on the guiding post 821, the rotating pressing plate 823 and the mounting frame 81 is provided with a spring 822, the spring 822 is sleeved on the guide post 821, and the end of the guide post 821 away from the spring 822 is provided with a nut 824 for pressing the rotating pressure plate 823, the center line of the guide post 821 and the outer surface of the slip ring 4 The tangent to the circumference is perpendicular. Through the spring 822, the carbon brush is always tangent to the outer surface of the slip ring 4, so as to improve the matching effect between the polished carbon brush and the on-site slip ring.

[0041] The present invention also provides another embodiment of the elastic pressing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com