Hole opening tool under pressure and hole opening process

A technology of opening and tooling with pressure, applied in metal processing and other directions, can solve problems such as affecting the working accuracy, no special device for handling PE pipe residual material, damage to PE pipe, etc., to increase practicability and safety, Improves usability and stability, and facilitates disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

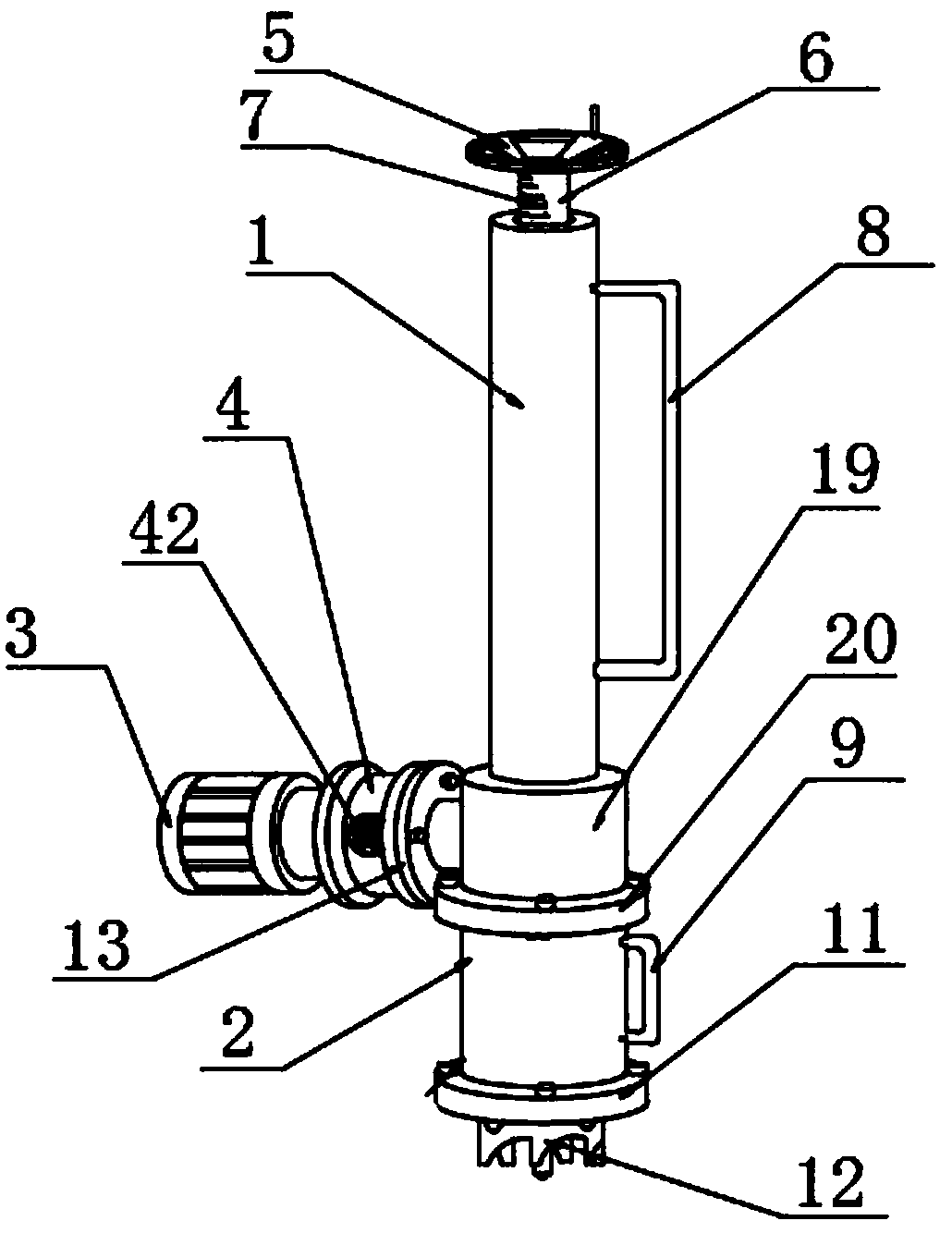

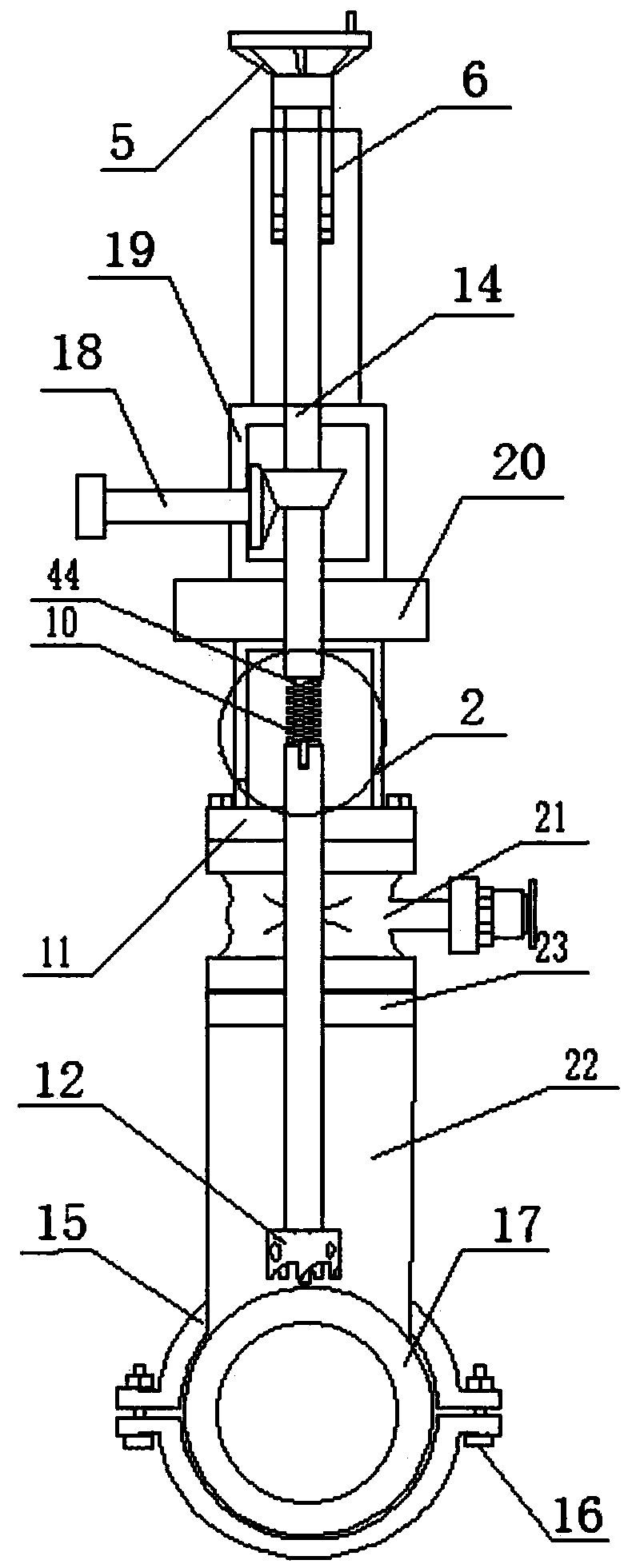

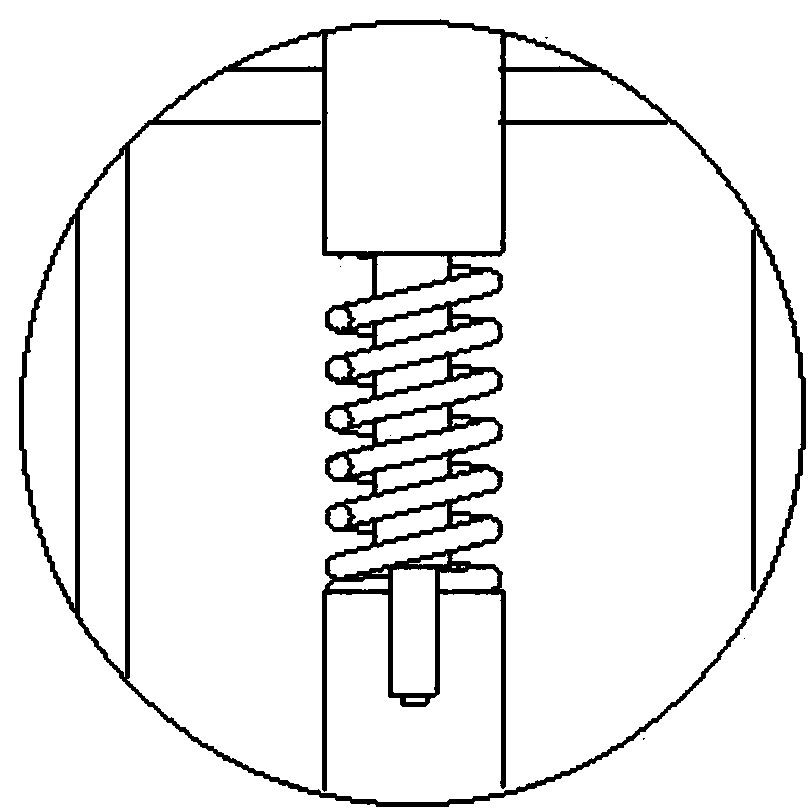

[0040] like figure 1 Shown is a structural schematic diagram of a pressure drilling tool, which includes a casing 1, a sealing chamber 2, a motor 3 and a transmission box 4, the bottom of the casing 1 is provided with a sealing chamber 2, and the transmission box 4 There is a motor 3 for powering it, the top of the protective shell 1 is provided with a hand wheel 5, and the tool shaft 14 is fixedly installed under the hand wheel 5, and a switch is fixedly connected to the bottom of the tool shaft 14. The hole cutter 12 and the tool shaft 14 are arranged in the protective shell 1 through a sliding bearing. In order to facilitate the staff to calculate the cutting depth, a scale tube 6 is arranged below the hand wheel 5, and the outside of the tool shaft 14 is sleeved There is a scale tube 6, the outer surface of the scale tube 6 is provided with a scale line 7, the scale tube 6 is fixedly connected with the tool shaft 14 through a bearing, the scale tube 6 is located below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com