Stainless-steel and carbon-steel composite plate and preparation method thereof

A technology for composite plates and stainless steel plates, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve problems affecting the corrosion resistance and use effect of composite plates, poor plate shape, and relatively poor research on intergranular corrosion performance. Less problems, to achieve the effect of improving the ability to resist intergranular corrosion, reducing the duration, and reducing the phenomenon of intergranular corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

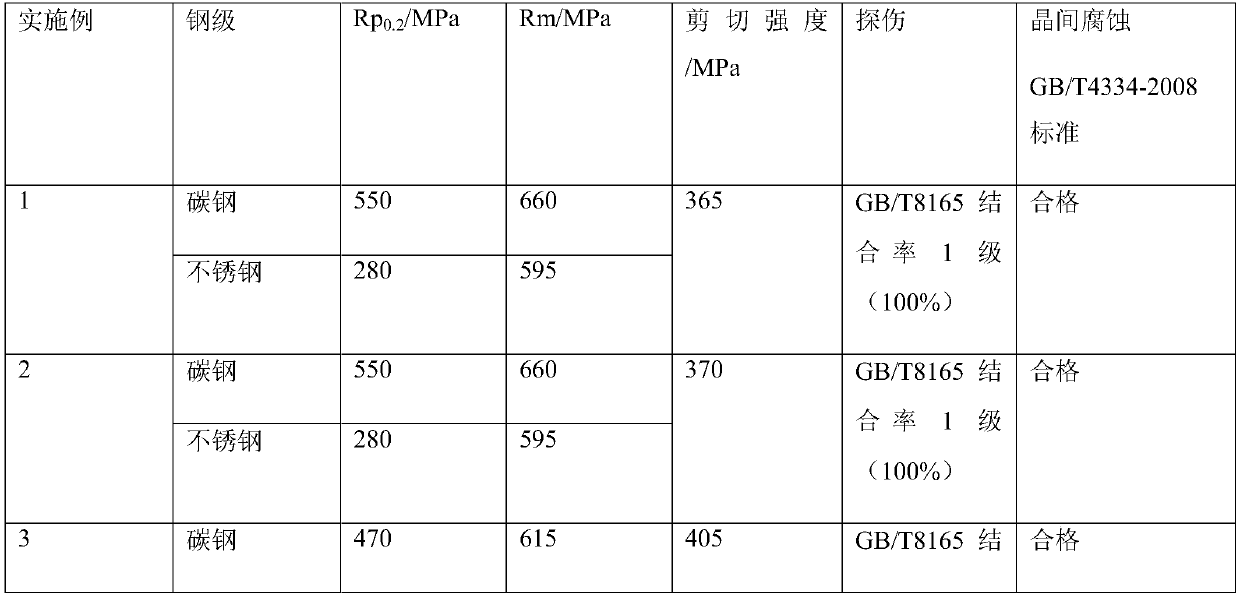

Embodiment 1

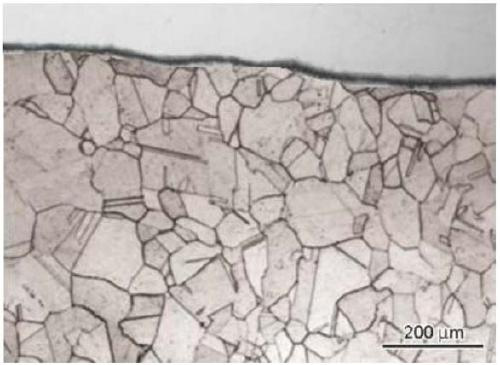

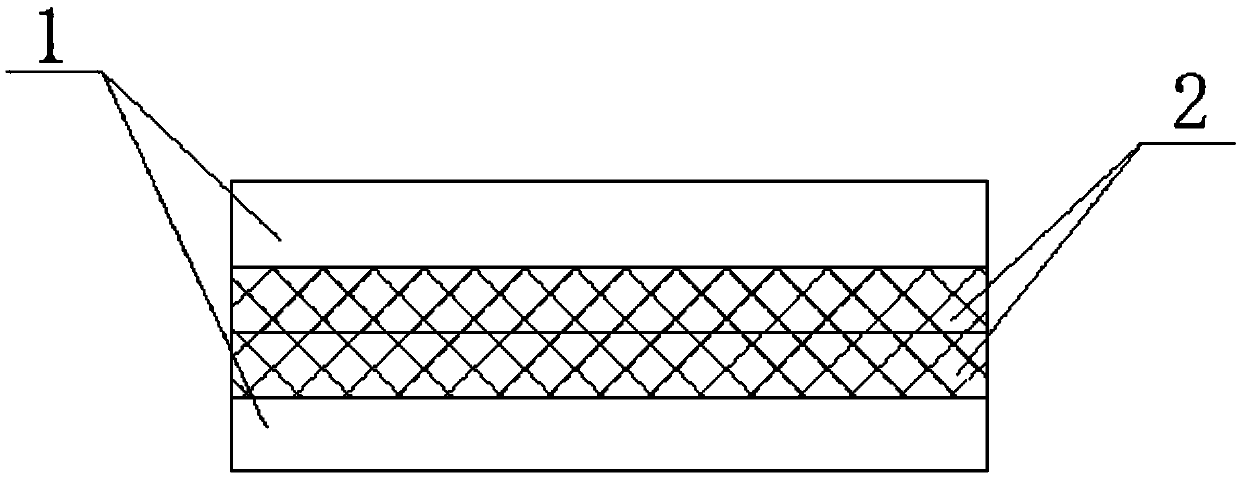

[0023] A stainless steel, carbon steel composite plate, the composite plate comprises carbon steel plate, stainless steel plate, stainless steel plate and carbon steel plate which are laminated sequentially; the metal component content of the carbon steel plate is: C0.18%, Si 0.25%, Mn0.8%, S0.02-0.025%, P 0.024%, Cr 0.05%, Nb0.04%, Al0.05%, Ni, 0.50%, and the balance is Fe; the metal component content of the stainless steel plate is : C 0.070%, Si 0.70%, Mn 1.6%, S 0.008%, P 0.04%, Cr19%, Ni12%, Nb0.03%, Al0.12%, Cu.035%, Ti 0.18-0.20%, balance For Fe.

[0024] Method of preparation:

[0025] (1) Symmetric billet assembly: the smelted carbon steel plate and stainless steel plate are superimposed and compounded in the order of carbon steel plate, stainless steel plate, stainless steel plate, and carbon steel plate; and the surfaces of the carbon steel plate and stainless steel plate that are in contact with each other are polished to expose the metal layer. Coat the surface ...

Embodiment 2

[0031]A stainless steel, carbon steel composite plate, the composite plate comprises carbon steel plate, stainless steel plate, stainless steel plate and carbon steel plate which are laminated in sequence; the metal component content of the carbon steel plate is: 0.16%, Si 0.22%, Mn0. 6%, S0.022%, P0.024%, Cr 0.045%, Nb0.03%, Al0.045%, Ni0.45%, and the balance is Fe; the metal component content of the stainless steel plate is: C 0.0. 072%, Si 0.70%, Mn 1.5%, S0.006%, P 0.036%, Cr18%, Ni8.5%, Nb0.03%, Al0.12%, Cu0.35%, Ti 0.19%, the balance is Fe; the thickness of the steel plate is 30mm, and the thickness of the stainless steel plate is 10mm.

[0032] The preparation method of the above-mentioned stainless steel and carbon steel composite plate, the preparation steps include:

[0033] (1) Symmetric billet assembly: the smelted carbon steel plate and stainless steel plate are superimposed and compounded in the order of carbon steel plate, stainless steel plate, stainless steel...

Embodiment 3

[0039] A stainless steel, carbon steel composite plate, the composite plate comprises a carbon steel plate, a stainless steel plate, a stainless steel plate and a carbon steel plate that are stacked in sequence; the metal component content of the carbon steel plate is: C0.20%, Si 0.30%, Mn0.8%, S0.023%, P0.024%, Cr 0.055%, Nb0.04%, Al0.055%, Ni0.55%, the balance is Fe; the metal component content of described stainless steel plate is: C, 0.074%, Si 0.70%, Mn 1.7%, S 0.008%, P 0.038%, Cr18.5%, Ni9%, Nb0.04%, Al0.13%, Cu0.40%, Ti0.19%, balance For Fe. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com