A double-pitch double-pin shaft heavy-duty conveyor chain

A conveyor chain, heavy-duty technology, applied in the field of double-pitch double-pin heavy-duty conveyor chains, can solve the problems affecting the chain movement accuracy and service life, high friction, loud noise, etc., to eliminate the polygon effect, The effect of reducing friction and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

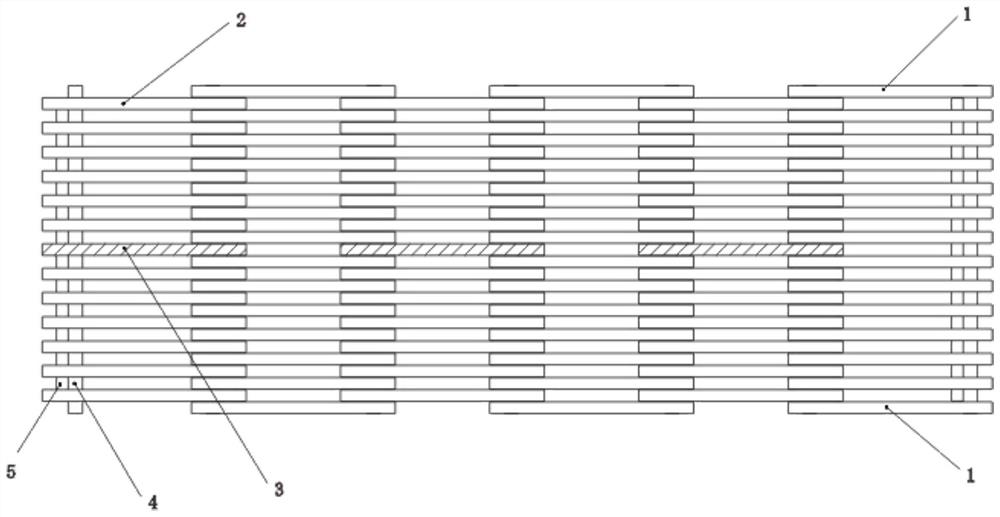

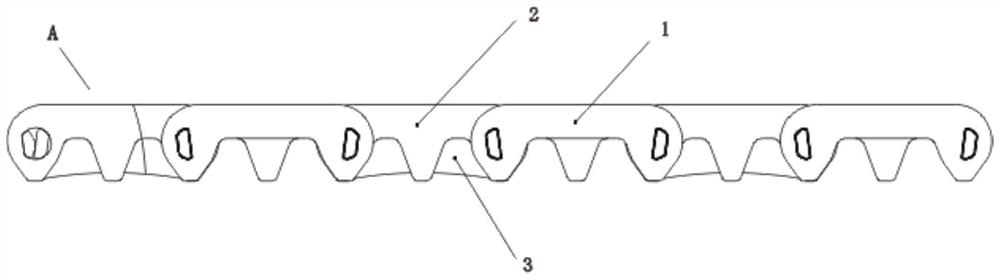

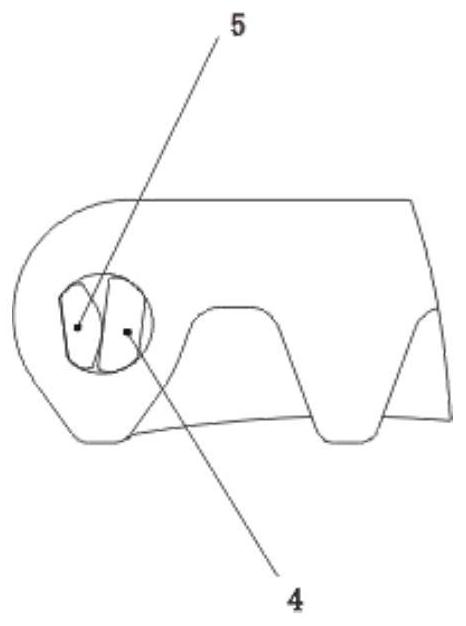

[0032] Such as Figures 1 to 7 The double-pitch double-pin shaft heavy-duty conveyor chain is assembled by connecting and assembling several chain link units, and the chain link unit includes an inner chain plate 2 ( Figure 5 is the shape of inner chain plate 2), outer chain plate 1 ( Figure 4 is the shape of outer chain plate 1), pin group ( Figure 7 is the shape of the long pin shaft 4, Figure 8 It is the shape of short pin shaft 5) and guide plate 3 ( Figure 6 is the shape of the guide plate 3), the inner chain plate 2 and the guide plate 3 are arranged inside the outer chain plate 1, and the guide plate 3 cooperates with the guide groove on the sprocket to limit the lateral movement of the conveyor chain ; The pin group includes short pins 5 and long pins 4 that can roll relatively; hole; the short pin shaft 5 and the long pin shaft 4 pass through the first shaft hole, and the short pin shaft 5 is restricted from rotating in the circumferential direction of the fi...

Embodiment 2

[0045] The basic structure of this embodiment is the same as that of the embodiment, the difference is that the two ends of the long pin shaft 4 protrude from the outer surface of the second shaft hole, and the two ends are connected with the outer chain by pressure riveting. Plate 1 is fixedly connected, and this connection mode will form a riveting head on the outside of outer chain plate 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com