A system and method for mixing distribution of large and small tanks on the top of a blast furnace

A technology of mixing cloth and cloth system, applied in the direction of bell and funnel arrangement, etc., can solve the problems of inability to realize grading and mass-separation loading of raw fuel, natural mixing and natural segregation, collision with the side wall of the material tank, etc. Short renovation period, reducing the effect of wind break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

[0030] For realizing above-mentioned purpose of the invention, the technical scheme that the present invention adopts is:

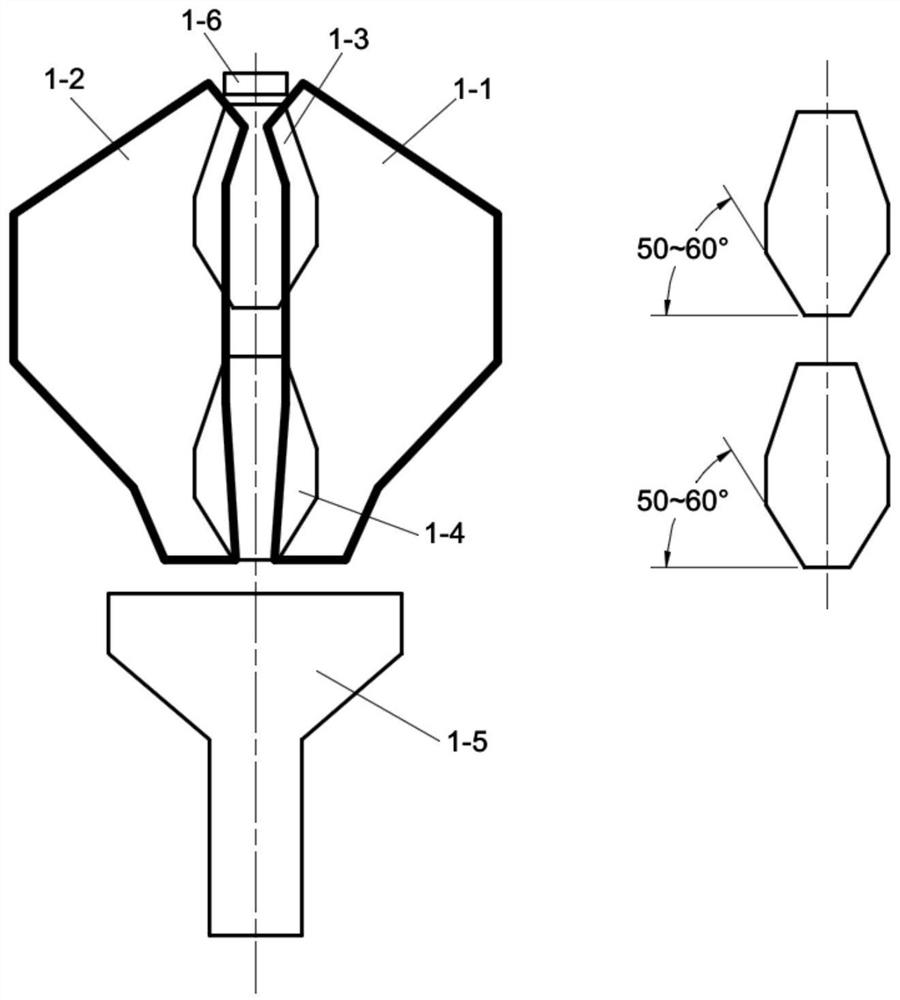

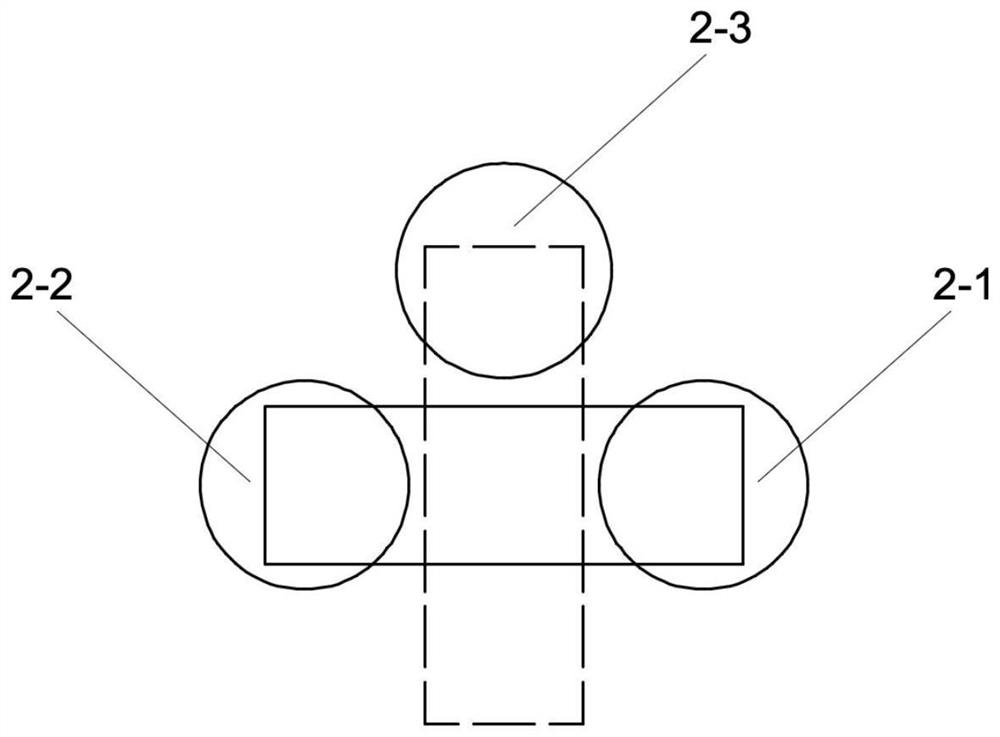

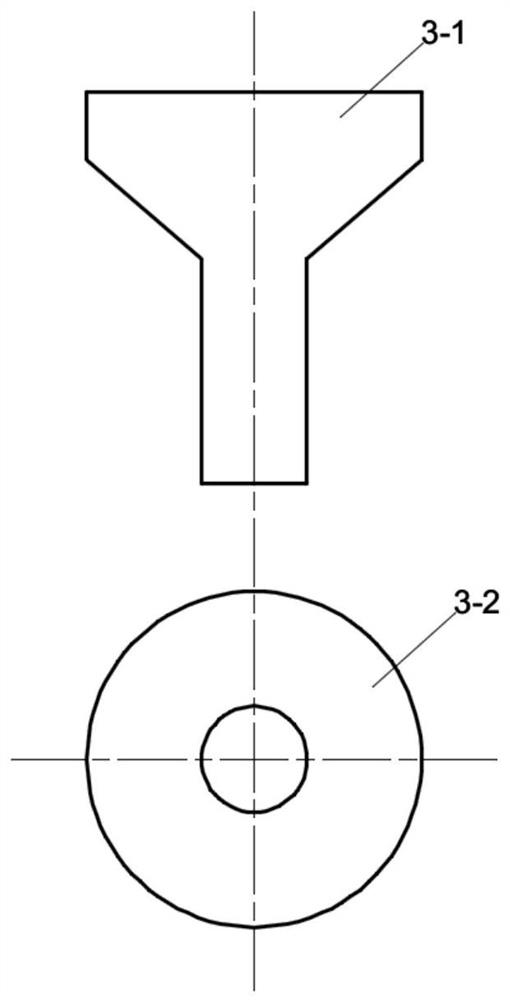

[0031] The invention discloses a mixing distributing system for large and small tanks on the roof of a blast furnace, which includes two large tanks, the east tank and the west tank, two small tanks, the upper small tank and the lower small tank, a flap chute and a central throat.

[0032] Two large tanks are arranged side by side, two small tanks are arranged in series in the height direction, and the two small tanks are arranged in series in the height direction, generally parallel to the large tank, and the rotation axis of the small tank is on the symmetrical plane of the two large tanks, and properly Move outward, and the moving distance is about 1 to 1.5 times the maximum cross-sectional diameter of the small tank. The vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com