Special fixture applied to aluminum thick film resistivity method vacuum evaporation device

A special fixture and resistance method technology, used in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of low limit thickness of evaporated aluminum film, and achieve the effect of improving the limit thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

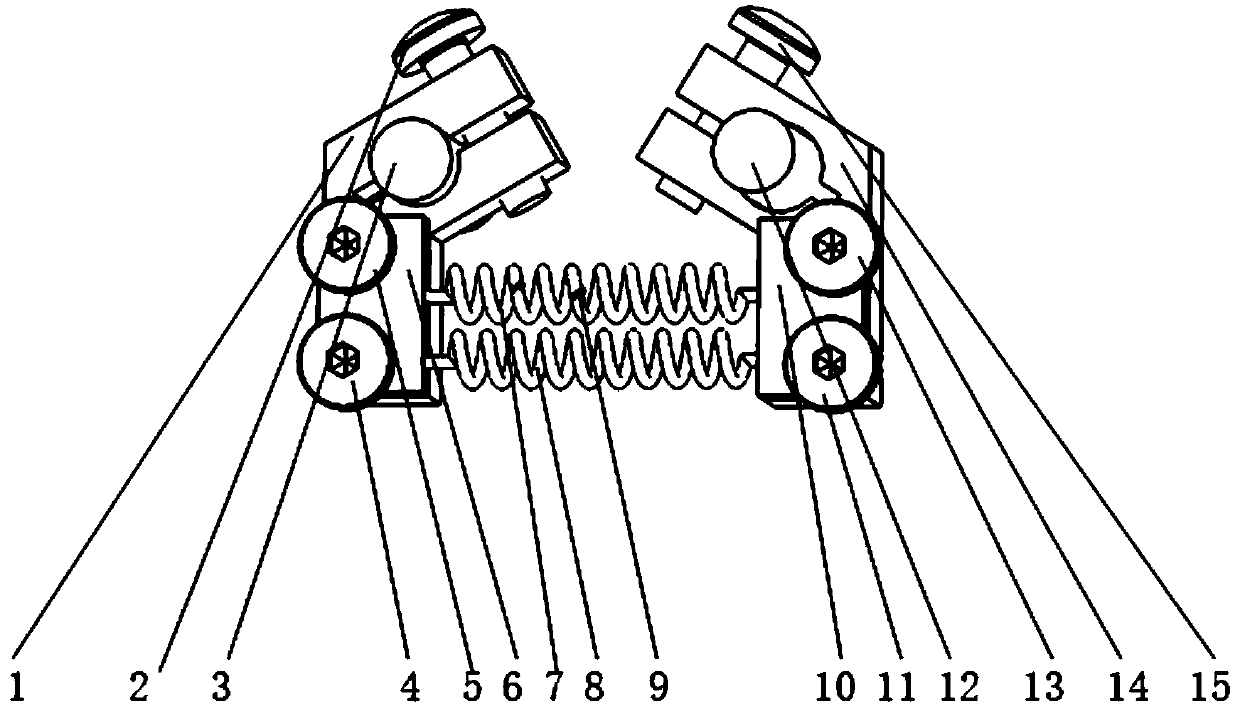

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

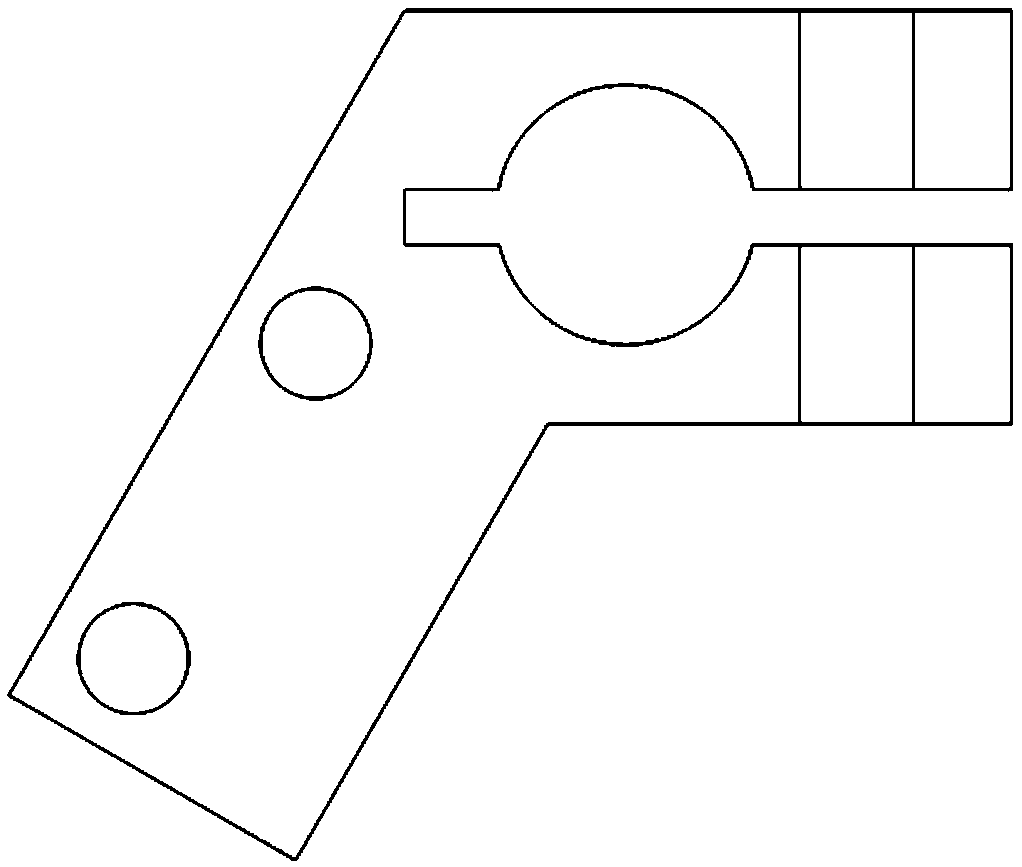

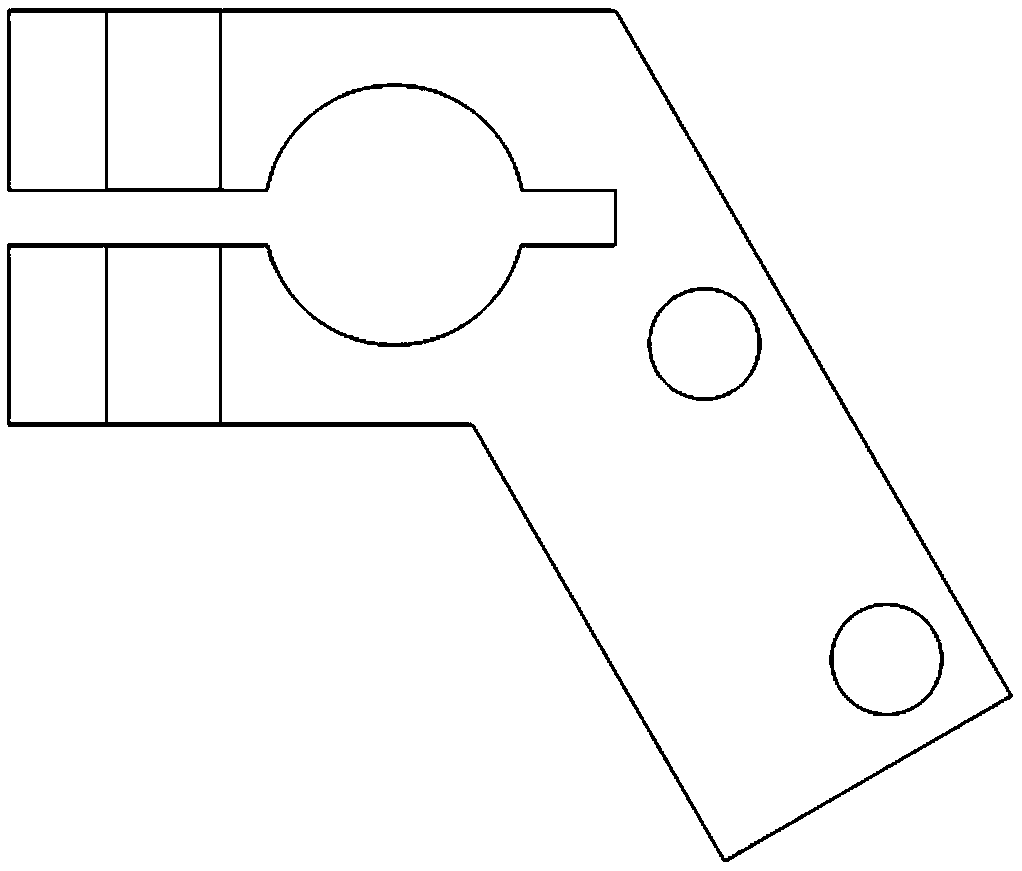

[0018] A special fixture used in resistance method vacuum evaporation aluminum thick film equipment, the special fixture has a left-right symmetrical structure, including a left fixture 1, a left electrode 3, a first tungsten wire cover plate 6, a first tungsten wire 7, a second Tungsten wire 8, aluminum ring 9, second tungsten wire cover plate 10, right electrode 13 and right clamp 14;

[0019] The left clamp 1 and the right clamp 14 cooperate with the first bolt 2 and the sixth bolt 15 respectively to clamp the left electrode 3 and the right electrode 12; the left clamp 1 and the right clamp 14 have the same structure, and are divided into fixed electrode terminals and Fixed tungsten wire end;

[0020] The first tungsten wire 7 and the second tungsten wire 8 are horizontally fixed between the left fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com