A bag sticking machine

A bag patching machine and driving mechanism technology, applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine housing, etc., can solve the problems of large floor area, low production efficiency, high production cost, etc., achieve high degree of automation and improve production Efficiency and the effect of increasing the operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

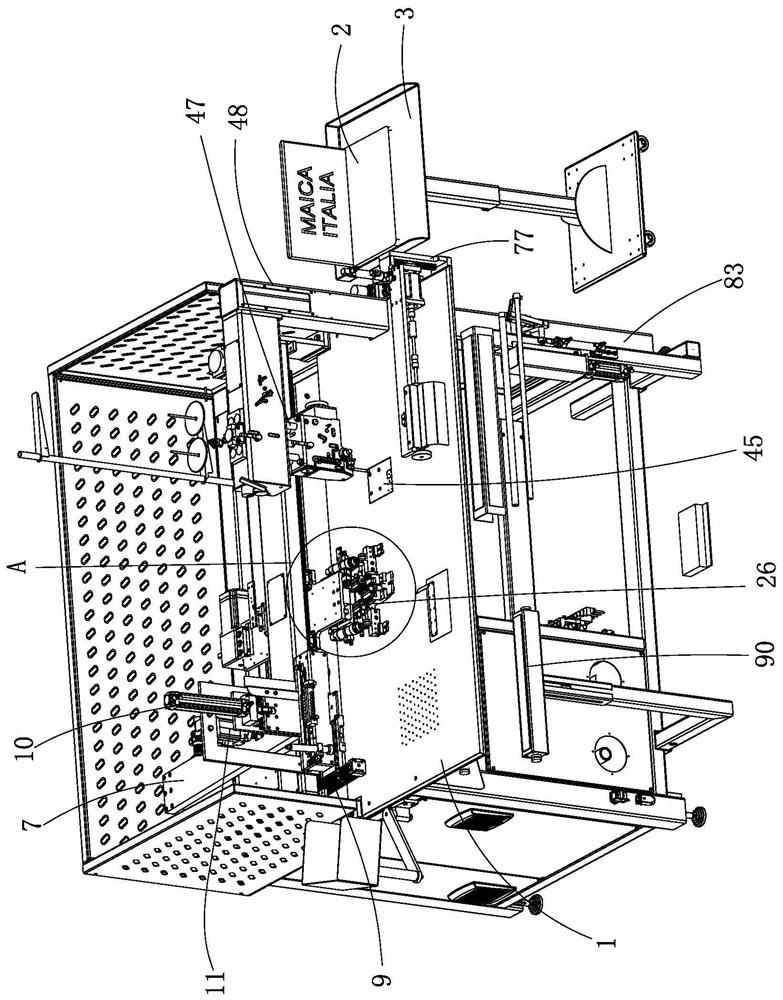

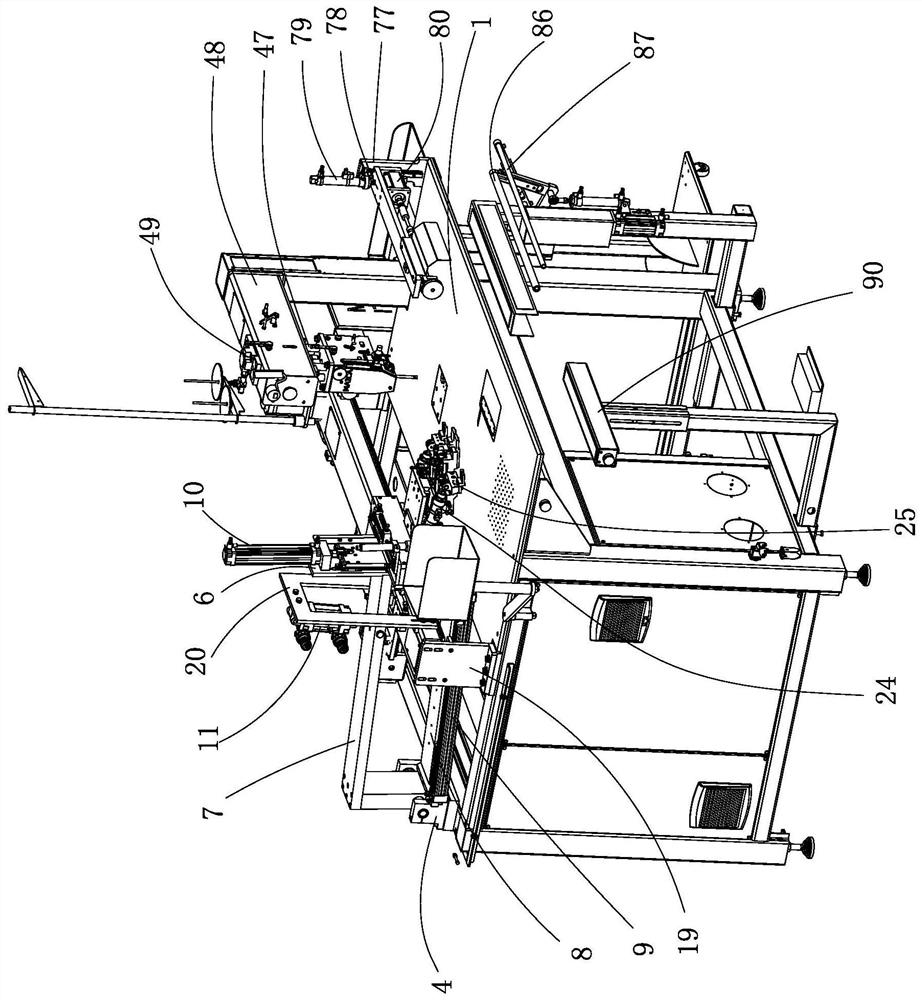

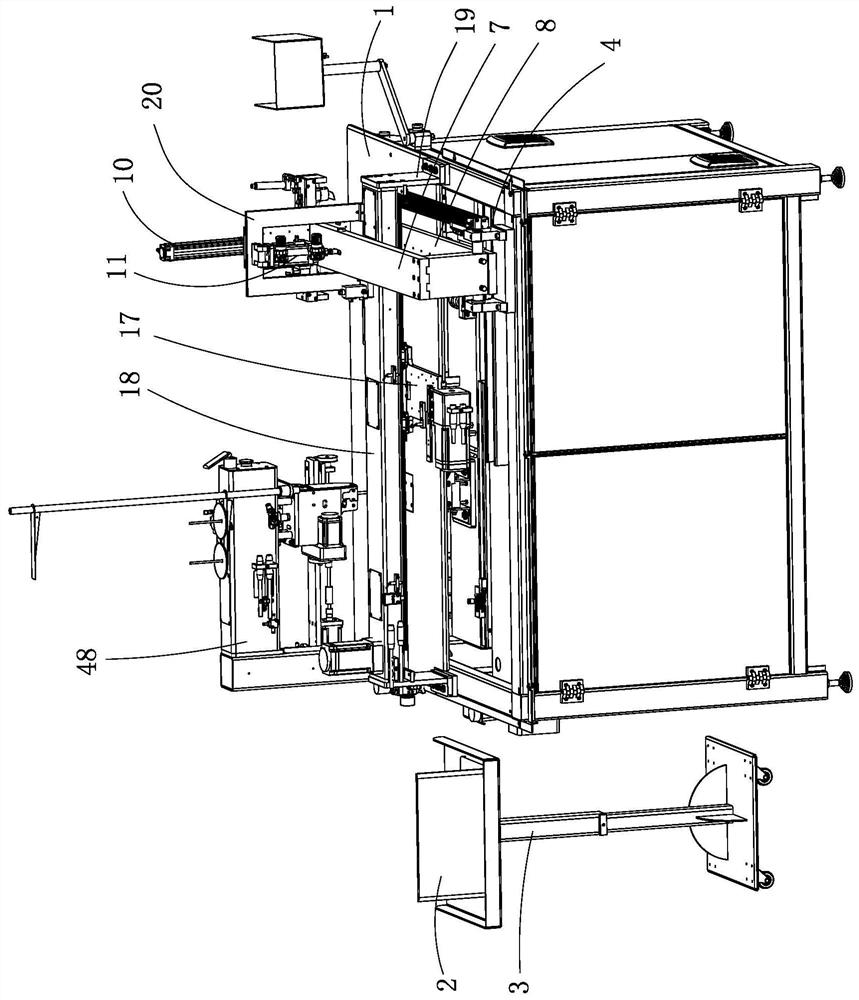

[0048] The present invention will be further described below with specific embodiment, see figure 1 -twenty four:

[0049] A bag sticking machine, comprising a workbench 1, a material folding device is provided on one side of the workbench 1, a sewing device is provided on the other side, a material transfer device is provided between the material folding device and the sewing device, the material folding device The actions of the device, sewing device and material transfer device are controlled by the controller.

[0050] In order to facilitate maintenance, inspection, debugging, etc., the operation panel of the controller of the present invention adopts a computer 2 . The computer 2 is arranged on one side of the workbench 1 through the computer rack 3 . The computer frame 3 is movable.

[0051] The material folding device of the present invention includes a support arm, the support arm is arranged longitudinally, the rear end of the support arm is hinged on the hinge sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com