Control box used for double-shift draining valve, and draining valve provided with control box

A control box and drain valve technology, applied in the field of sanitary ware, can solve the problems that the full row and half row can be out of control at the same time, the discharge volume of the drain valve is different, and the discharge volume is unstable, etc., and achieves ingenious structural design, reliable function and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

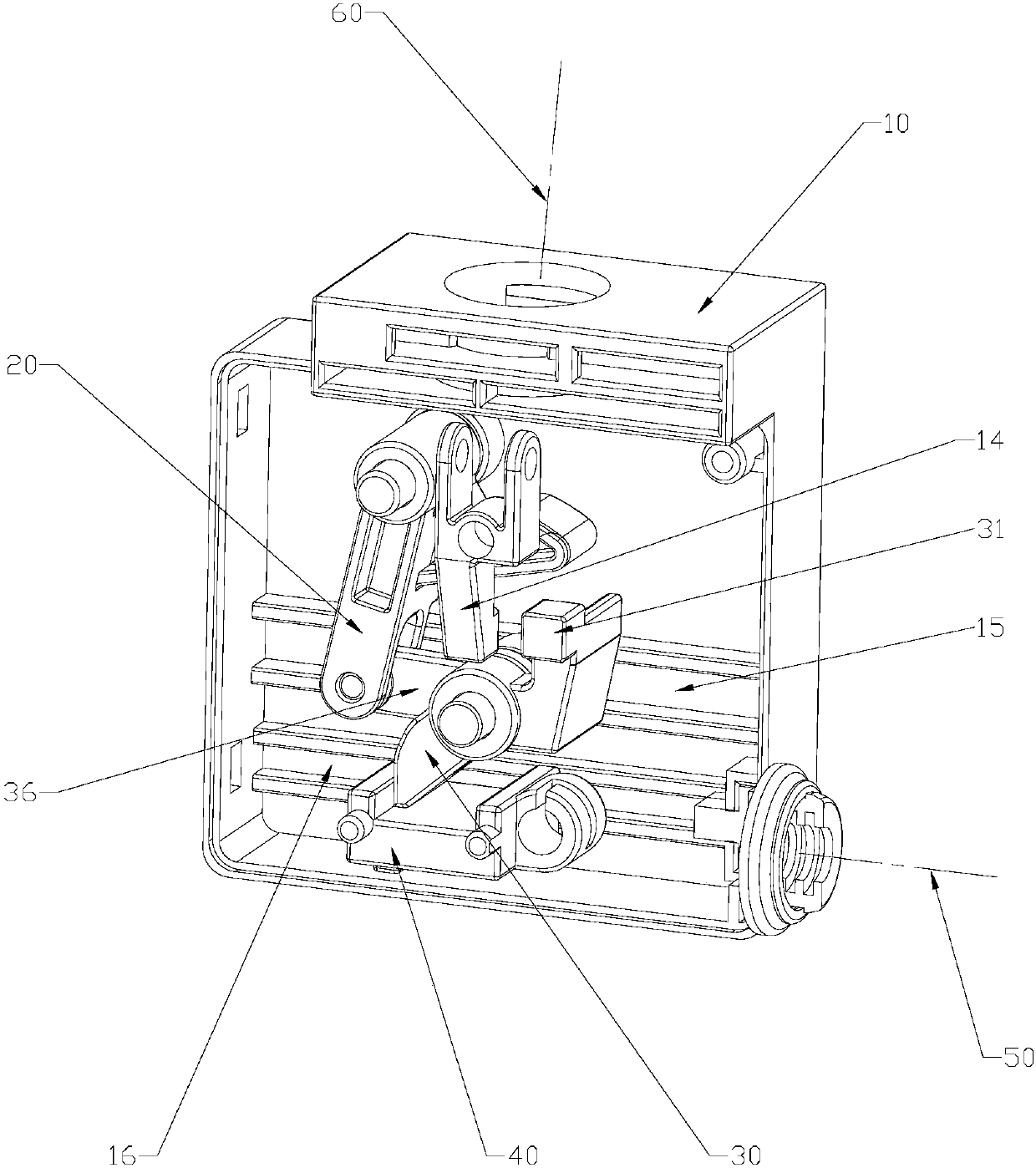

[0060] Such as Figure 1 to Figure 4 As shown, in this embodiment, the transmission body 30 is mounted on the box body 10 in a manner of swinging and sliding; The two ends of the rod 36 are pivotally engaged with the rotating body 20 and the transmission body 30 respectively; Cooperating abutment block 31 . When the transmission body 30 moves to match with the full-row limit block 13 or the half-row limit block 14, under the action of the full-row limit block 13 or the half-row limit block 14 The movement gives way, so that the transmission between the rotating body 20 and the sliding body 40 is disconnected.

[0061] The full row of limit blocks 13 are fixedly arranged on the box body 10, and the half row of limit blocks 14 are movably arranged on the box body 10. In this embodiment, the half row of limit blocks 14 swing Or slidingly mounted on the box body 10; on the movement stroke of the rotating body 20, the transmission body 30 and the sliding body 40, the half-row li...

no. 2 example

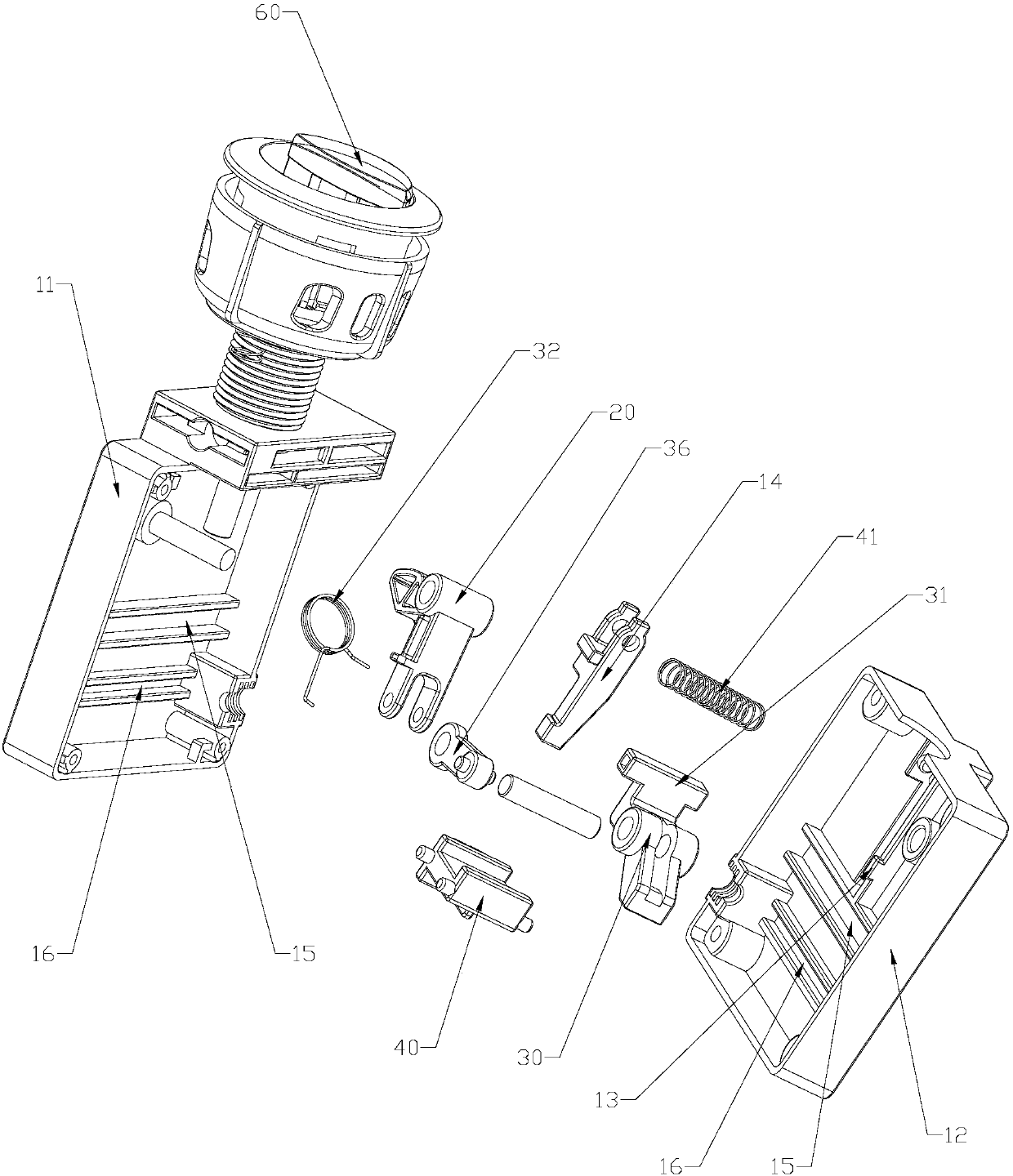

[0074] Such as Figure 5 and Figure 6 As shown, the main difference between this embodiment and the first embodiment is: in this embodiment, no connecting rod 36 is provided between the rotating body 20 and the transmission body 30, and the first sliding groove 15 is provided On the rotating body 20 , the transmission body 30 is rotatably mounted on the first sliding groove 15 and can slide along the first sliding groove 15 .

[0075] Such as Figure 5 As shown, in the initial state, the transmission body 30 and the sliding body 40 abut against each other.

[0076] Such as Figure 6As shown, when the half-row switch 62 is pressed down, the rotating body 20 is driven to rotate, and the rotating body 20 further pulls the transmission body 30, and the transmission body 30 further drives the sliding body 40 to move; position, the abutment portion 31 of the transmission body 30 abuts and cooperates with the half-row limit block 14, and is limited by the half-row limit block 14...

no. 3 example

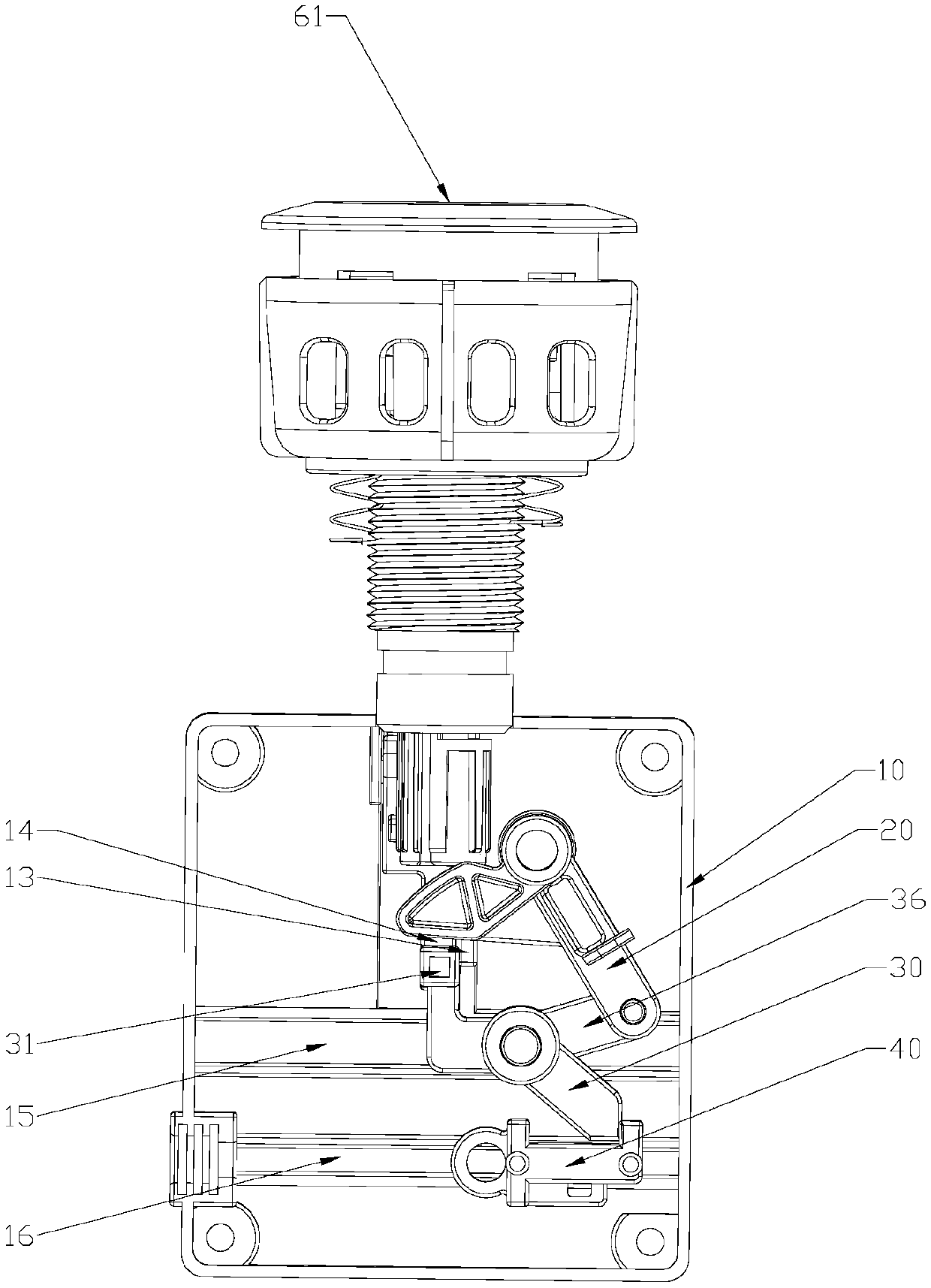

[0079] Such as Figure 7 and Figure 8 As shown, the main difference between this embodiment and the first embodiment is: in this embodiment, the transmission body 30 is slidingly fitted with the first sliding groove 15, and the sliding fit includes left and right sliding fit and front and rear sliding fit.

[0080] Such as Figure 7 As shown, in the initial state, the transmission body 30 and the sliding body 40 abut against each other.

[0081] Such as Figure 8 As shown, when the half-row switch 62 is pressed down, the rotating body 20 is driven to rotate, the rotating body 20 drives the connecting rod 36 and further pulls the transmission body 30, and the transmission body 30 slides left and right in the first sliding groove 15 to drive the sliding body 40 movement; when the transmission body 30 moves to the position that cooperates with the half-row limit block 14, it is limited by the half-row limit block 14, and the transmission body 30 slides back and forth in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com