Two-way adjusting valve element and two-way adjusting valve

A technology for regulating valves and spools, applied to valve devices, sliding valves, mechanical equipment, etc., can solve the problems of pressure difference, large difference between cold water and hot water pressure, difficult adjustment, etc., and achieve the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

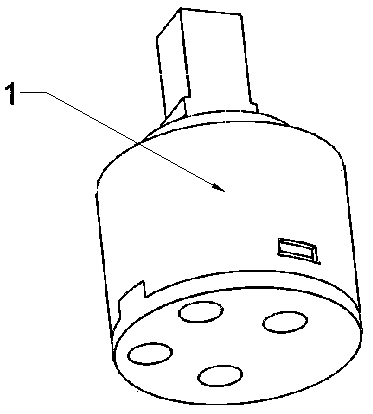

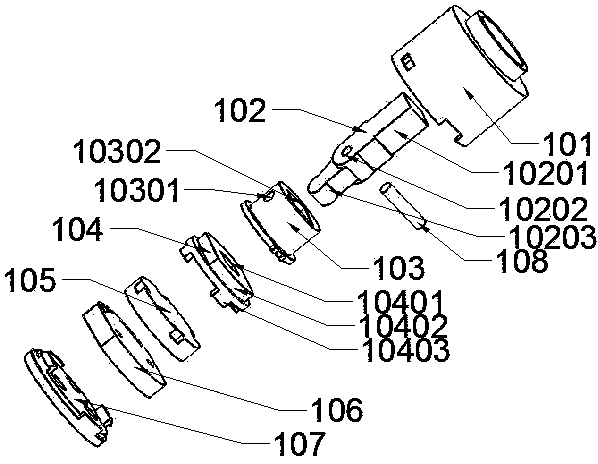

[0034] The present invention draws lessons from the design of the traditional water mixing valve, and redesigns the valve core and the valve on this basis. Figure 1-Figure 2 Two-way regulating valve core 1, including valve core housing 101, valve stem 102, valve stem support 103, valve stem connection block 104, dynamic sealing block 105, static sealing block 106, valve core bottom cover 107, wherein the valve cover base 107 has four through holes respectively corresponding to the cold water inlet 10605 of the static sealing block, the hot water inlet 0606 of the static sealing block, the cold water outlet 10607 of the static sealing block, and the hot water outlet 10608 of the static sealing block, wherein the valve core housing 101 is a center The hollow structure has a hole on the upper part to allow the valve stem connecting column 10201 to pass through and to rotate and move forward and backward. The sequential movement of the valve stem connecting column 10201 described ...

Embodiment 2

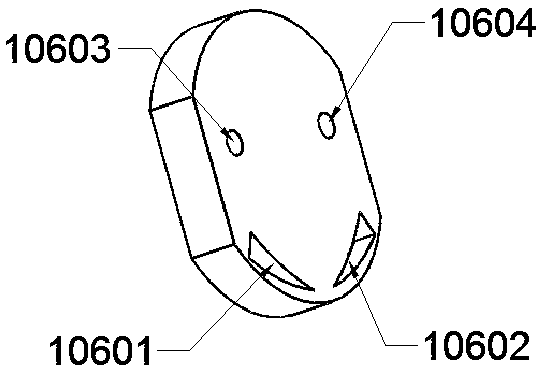

[0038] refer to Figure 12-Figure 14 , Figure 14 This embodiment provides another kind of dynamic sealing block cold water channel 10503, dynamic sealing block hot water channel 10504, static sealing block cold water outlet channel 10603, and static sealing block. The basic shape of the hot water outlet channel 10604 of the block, its connection mode and adjustment mode are consistent with the embodiment, and can also meet the purpose of the first embodiment, that is, the translation and rotation of the dynamic sealing block 105 can be realized by turning and rotating the valve stem connecting column 10201 , through the reasonable adjustment of these two adjustment methods, the adjustment of different cold water and hot water flows can be realized. The overlapping area of the channel 10503, the cold water outlet channel 10603 of the static sealing block, the hot water channel 10504 of the dynamic sealing block, and the hot water outlet channel 10604 of the static sealing b...

Embodiment 3

[0040] This embodiment provides a two-way regulating valve designed with a two-way regulating spool, refer to Figure 15-Figure 17 .

[0041] refer to Figure 16 Two-way regulating valve, the two-way regulating valve mainly includes, valve core 1, valve handle 201, spherical cover 202, bolt 203, gear cover 204, gland 205, valve body 206, valve body 206 includes: cold water inlet pipe 20601, hot water inlet pipe 20602, cold water outlet pipe 20603, hot water outlet pipe 20604, valve body cold water outlet hole 20605, valve body hot water outlet hole 20606, valve body cold water inlet hole 20607, valve body cold water Water inlet hole 20608, valve core fixing seat 20609, the internal channel of the valve core fixing seat 20609 can connect the cold water inlet pipe 20601 with the valve body cold water inlet hole 20607, the valve body cold water outlet hole 20605 and the cold water outlet pipe 20603, The hot water outlet pipe 20604 communicates with the hot water outlet hole 206...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com