Method for distinguishing unreal rotating shaft vibration signals of steam turbine generator unit

A steam turbine generator set, vibration signal technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc. Report and reduce the effect of unplanned downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

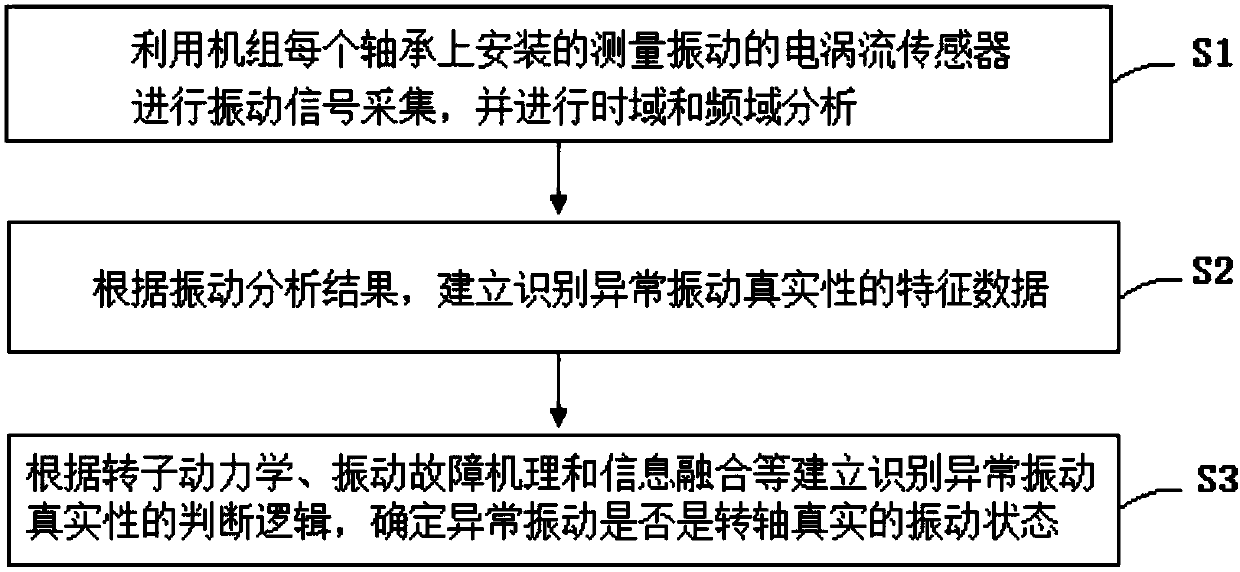

Image

Examples

Embodiment 330

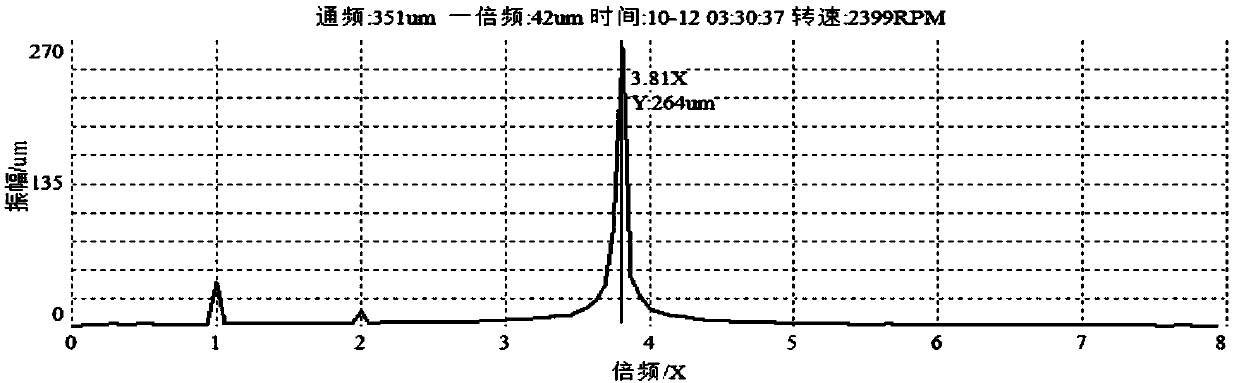

[0037] This embodiment takes a 330MW turbogenerator set as an example. The set is composed of a high-voltage rotor, a medium-pressure rotor, a low-pressure rotor and a generator rotor. Each bearing is equipped with X-direction and Y-direction eddy current sensors to measure the relative vibration of the shaft. On-line vibration monitoring and analysis system. The unit was started after overhaul. During the start-up process, as the speed increased, the vibration gradually increased. At about 2400r / min, the vibration of the 2# bearing (rear bearing of the high-pressure rotor) in the X direction increased rapidly, and the frequency spectrum was mainly 3.81 multiplied. Such as figure 2 As shown, the vibration in the Y direction is normal, which is in line with logic 5: the vibration signals of two eddy current sensors on the same bearing, one of which has a non-integer high frequency vibration, is not the real vibration of the rotor. According to the analysis, resonance occurred...

Embodiment 600

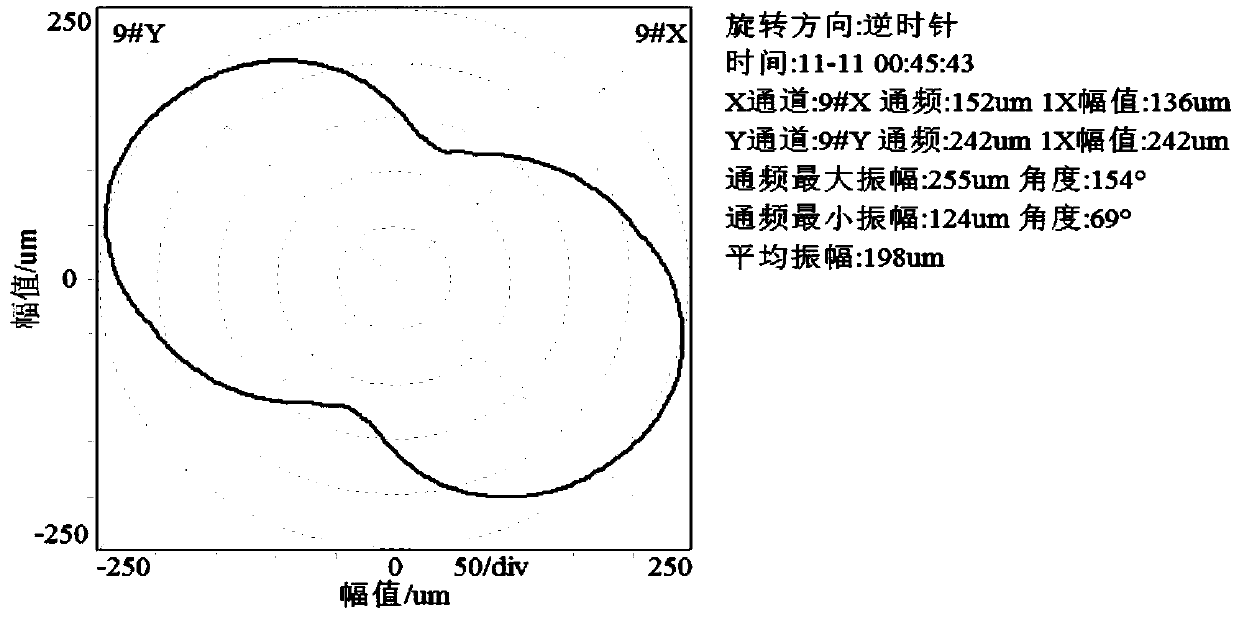

[0039] This embodiment takes a 600MW turbogenerator set as an example. The set is composed of a high-voltage rotor, a medium-pressure rotor, two low-pressure rotors and a generator rotor. There are 10 bearings in total, and each bearing is equipped with X-direction and Y-direction eddy current sensors. To measure vibration, the unit is equipped with an online vibration monitoring and analysis system. When the unit is about to be overhauled, the X- and Y-direction vibrations of the 9# bearing (the front bearing of the generator rotor) gradually increase, and the frequency spectrum is dominated by double frequency. In the bearing vibration diagram, such as image 3 As shown, it can be seen that the amplitude changes continuously along the circumferential direction, which is the real vibration of the rotor. Although the Y-direction vibration is obviously greater than the X-direction vibration, and the maximum amplitude has exceeded the dangerous value, but because the protection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com