A Method for Realizing Cable Electromagnetic Compatibility

An electromagnetic compatibility and cable technology, applied in the direction of circuit, electrical components, cable/conductor manufacturing, etc., to improve the electromagnetic shielding effect and ensure the effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

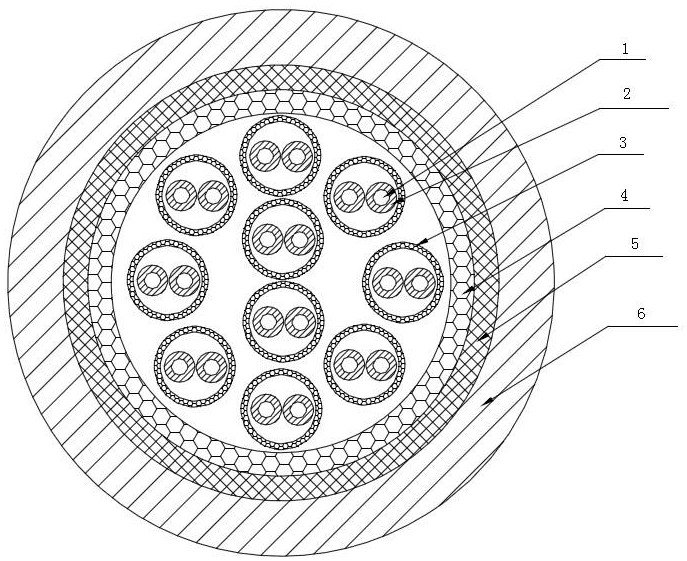

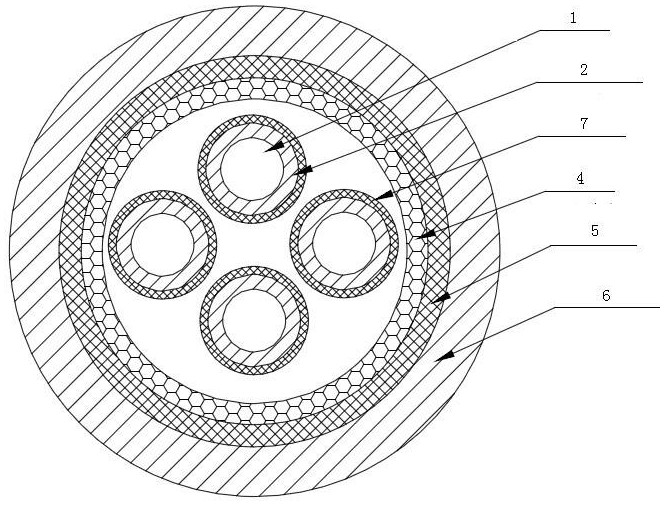

[0020] A method for realizing cable electromagnetic compatibility, characterized in that, said method for realizing electromagnetic compatibility comprises the following steps:

[0021] S1: Peel off the outer rubber of the cable at the place where the cable enters and exits the device;

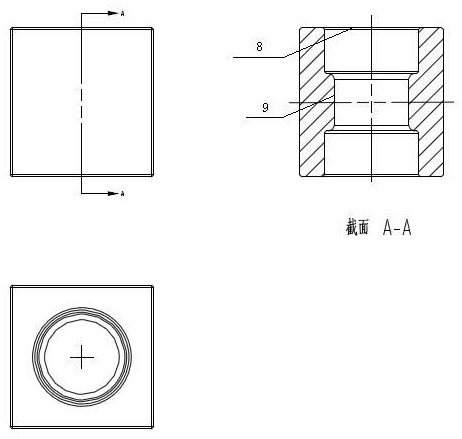

[0022] S2: Put the sealant rubber sleeve on the peeling part of the cable, and the rubber sleeve is required to form an interference fit with the outer rubber layer of the cable, the cable shielding layer and the casing.

[0023] In this embodiment, the method for realizing cable electromagnetic compatibility is characterized in that the front and rear of the rubber sleeve are respectively unilaterally interference fit with the rubber circumference of the cable by 0.15-0.25mm to achieve a waterproof seal Function: The middle step of the rubber sleeve and the circumference of the cable shielding layer have a unilateral interference fit of 0.15-0.25mm, and the surroundings of the rubber sleeve a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com