High voltage isolation transformer

A high-voltage isolation and transformer technology, applied in the direction of transformers, transformer/inductor components, transformer/inductor coils/windings/connections, etc., can solve the problems of difficult to expand the voltage level, difficult to control partial discharge, unfavorable winding heat dissipation, etc. Achieve the effect of reducing the difficulty of insulation design and manufacturing process and volume, low partial discharge design, and small structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

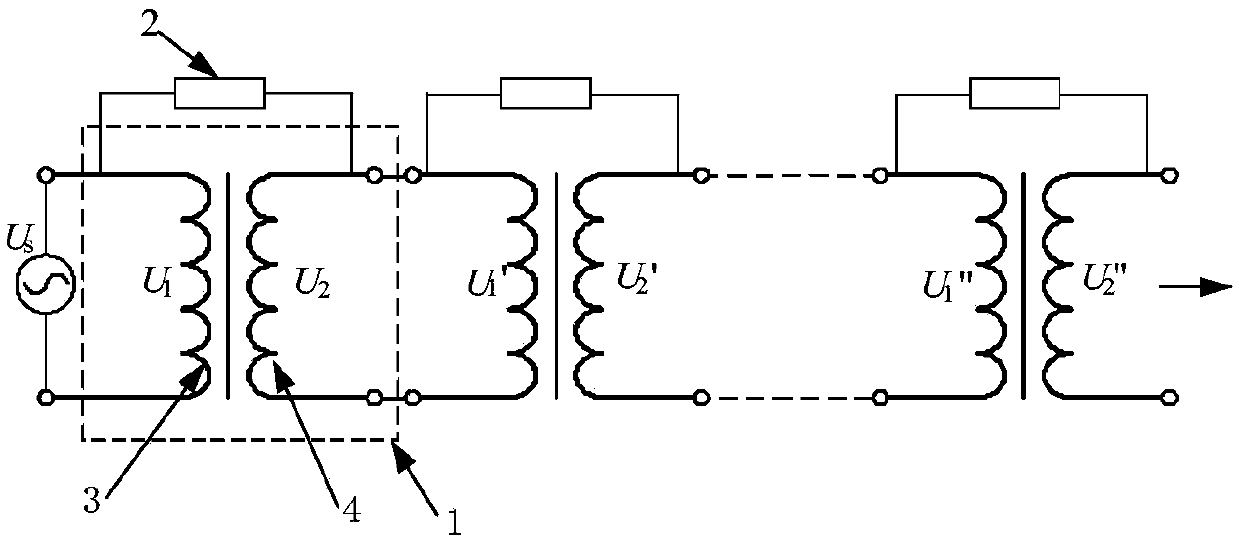

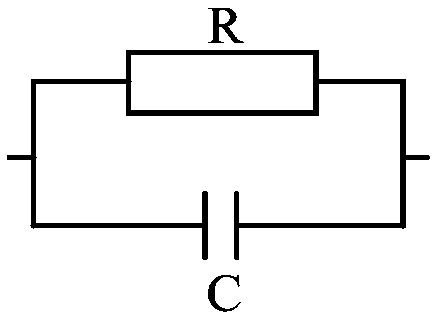

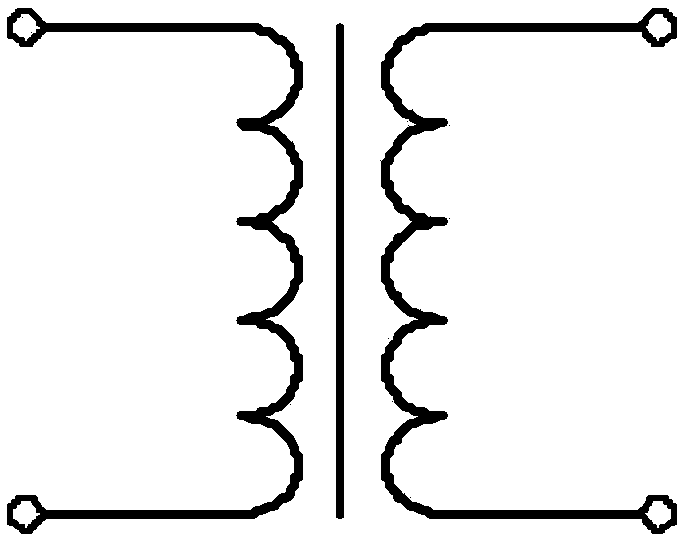

[0056] The high-voltage isolation transformer provided by the embodiment of the present invention is based on a solid insulation structure, adopts a unique structural form and insulation structure, and can realize a dry-type structure design in the voltage range of tens of kilovolts to hundreds of kilovolts, and can realize different voltages at the same time Partial discharge-free design under class. The high-voltage isolation transformer provided by the embodiment of the present invention is formed by cascading several sub-transformers with solid insulation structure. The number of cascading depends on the voltage level of the application. The voltage level of the sub-transformer can be flexible from tens of kilovolts to hundreds of kilovolts. design. Each sub-transformer includes high and low voltage winding structures, iron cores, support structures and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com