Air-dried tea, and processing method and air-drying rack for air-dried tea

A technology of tea and racks, which is applied in the field of traditional tea processing, can solve the problems of time-consuming and labor-consuming, and the natural pekoe of white tea is easily damaged, and achieve the advantages of high efficiency, excellent quality, and reduced mechanical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

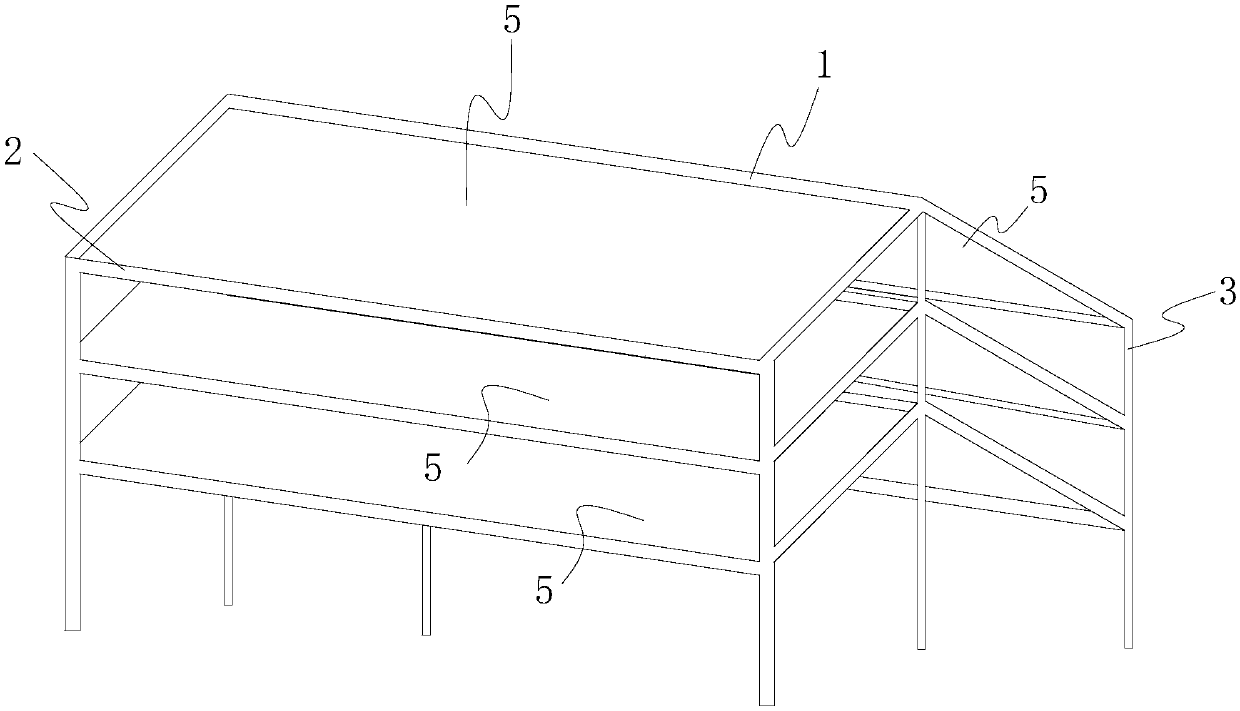

[0066] like Figure 1-4 The shown tea drying platform includes a skeleton structure and an inclined drying platform. The frame structure includes a vertically arranged central support frame group 1 and side support frame groups 2, 3, and connecting rods 4 are arranged between the central support frame group 1 and the side support frame groups 2, 3. The connecting rods 4 between the central supporting frame group 1 and the side supporting frame groups 2 and 3 are combined to form a hollowed-out slope, and the side of the connecting rods close to the central supporting frame group 1 is higher. Cloth 5 is arranged on the hollowed-out inclined surface to form a drying table 5 arranged obliquely.

Embodiment 2

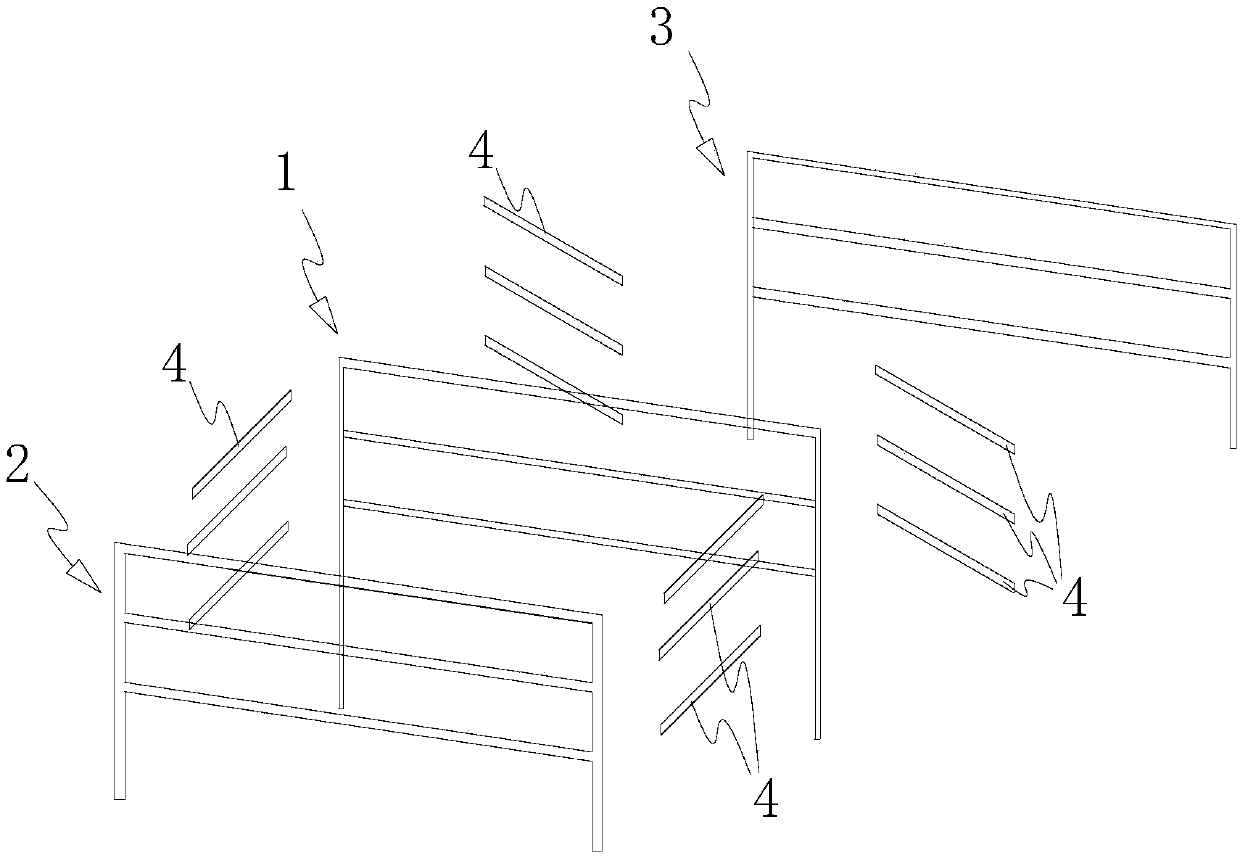

[0068] like figure 2 As shown in the exploded view, the central support frame group 1 and the side support frame groups 2 and 3 on the front and rear sides form inclined planes through a plurality of connecting rods 4 . Both ends of the connecting rod 4 can be fixedly connected by bolts, or can be directly connected permanently by welding.

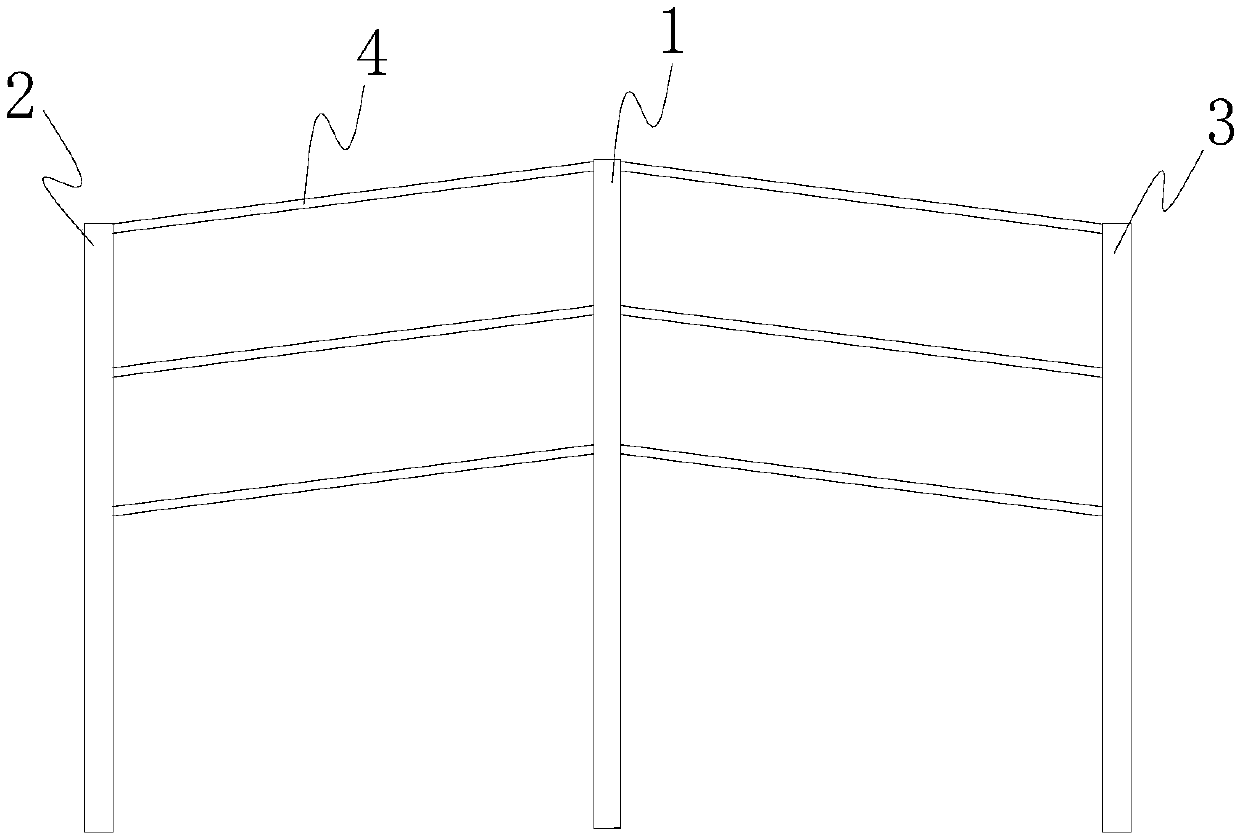

[0069] in such as figure 2 After the skeleton structure shown is assembled, as image 3 As shown in the right side view, a plurality of inclined planes hollowed out in the center are formed, white cotton cloths of matching sizes are arranged on these inclined planes, and the left and right sides of the cotton cloths are fixed with dovetail clips. The cotton slope after fixing is as Figure 4 As shown in the front view, multiple cloth drying tables are parallel to each other, presenting an inclination of 5° (relative to the horizontal plane), and tea leaves are spread on the cotton cloth drying table 5 (inclined plane), and the tea lea...

Embodiment 3

[0073] like Figure 5 As shown, multiple tea drying stands are arranged in a team to dry the tea leaves. When the breeze blows, the air flows through each cloth drying stand in turn. Each cloth drying stand is a wave-shaped protrusion. The air and tea The effect is good, and the tea drying / shade drying dehydration speed is appropriate, without additional manual intervention.

[0074] further, such as Image 6As shown, a sunshade net frame 6 is also arranged on the top of the drying stand, and the sunshade net frame 6 is installed and fixed with the sunshade net 7 to realize the necessary shade assistance for drying tea leaves. If the sun is too strong, or the processed tea needs good shading treatment, then install a sunshade rack to achieve a suitable light intensity, and realize adjustable and controllable tea drying and production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com