Composite filter rod with embedded mixed material section

A technology of composite filter rods and mixed materials, which is applied in the fields of e-liquid filter, food science, application, etc., can solve the problems of unstable and consistent filtration or aroma enhancement, and achieves improved filtration retention effect, good filtration effect, and good visual change effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

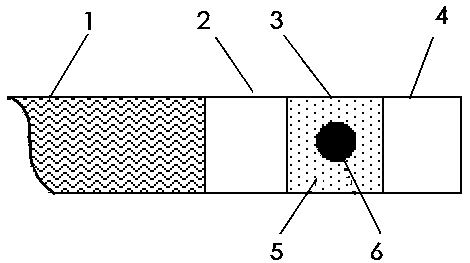

[0021] Such as figure 1 The composite filter rod with pre-embedded mixed material section shown is made of ordinary filter section, pre-embedded material section and common filter section arranged and combined in a certain proportion. It is characterized in that: the pre-embedded material section has a transparent outer cladding and There are many small particles located in the outer cladding, the size of the small particles ranges from 10 to 100 mesh, there are gaps between the small particles, and they can roll freely in the outer cladding; the surface of the small particles is loose and porous, and the main ingredients for making small particles are Natural or modified plant or mineral material. The ingredients for making small particles contain tobacco spices or other flavor flavors and fragrances.

[0022] A capsule with a diameter of 2.5-5mm is embedded in the middle of the small particles. The capsule is composed of a wall material and a core liquid. The core liquid is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com