Mutual-impacting-type chemical raw material stirring and mixing device

A chemical raw material, stirring and mixing technology, which is applied to mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve problems such as poor mixing effects, and achieve the effects of convenient operation, simple structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

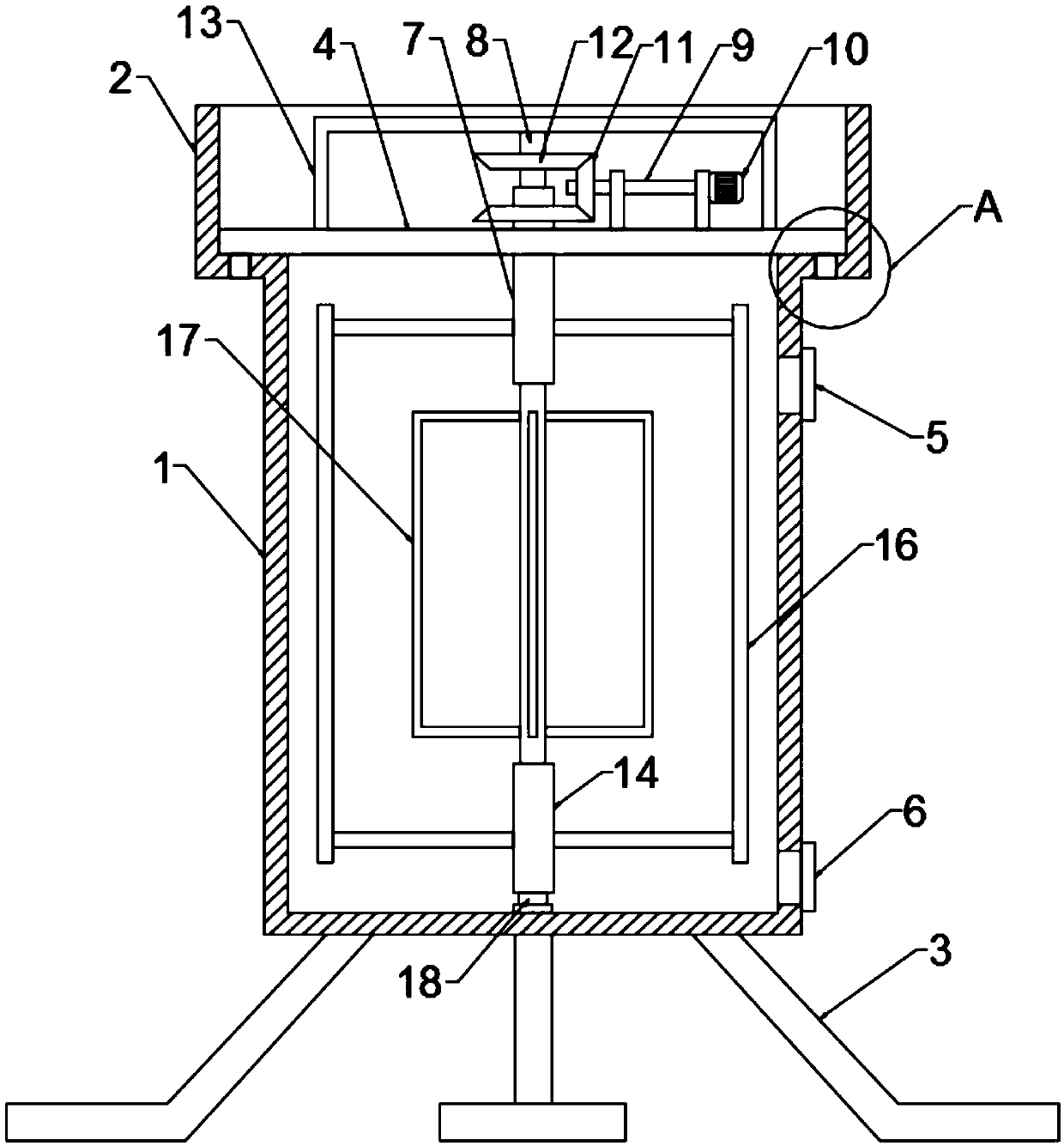

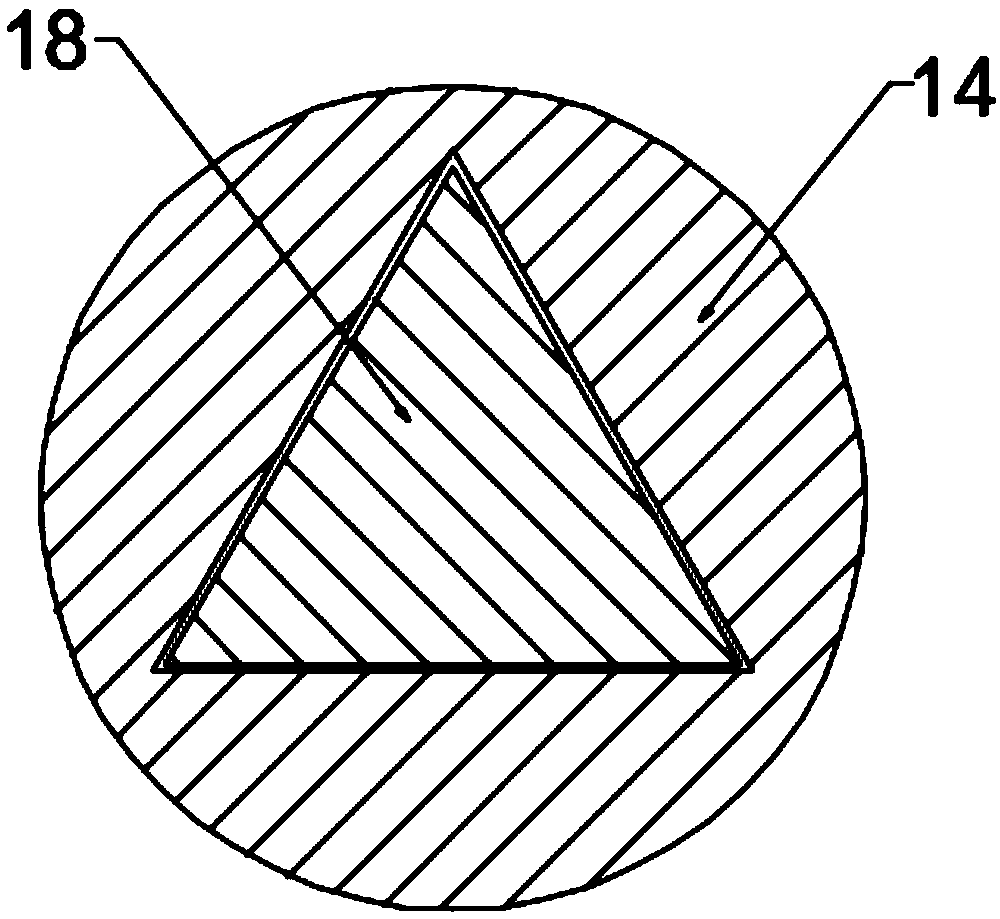

[0021] see Figure 1~4 , in an embodiment of the present invention, a mutual impact type chemical raw material stirring and mixing device includes a mixing cylinder 1 and a placement port 2 connected to the upper end of the mixing cylinder 1 as a whole, and the size of the placement port 2 is larger than that of the mixing cylinder. The top port of the cylinder body 1, the installation cover 4 is installed inside the placement port 2, and the bottom wall edge of the installation cover 4 is connected with the bottom wall of the placement port 2 through a limited clamping mechanism. A plurality of defined protrusions 29 on the bottom wall of the board 4 and a plurality of defined through grooves 28 arranged on the bottom wall of the placement port 2, the defined protrusions 29 correspond to the defined through grooves 28 one by one and the defined protrusions 29 are inserted into the The inner side of the through groove 28 is limited, and then the degree of freedom of rotation o...

Embodiment 2

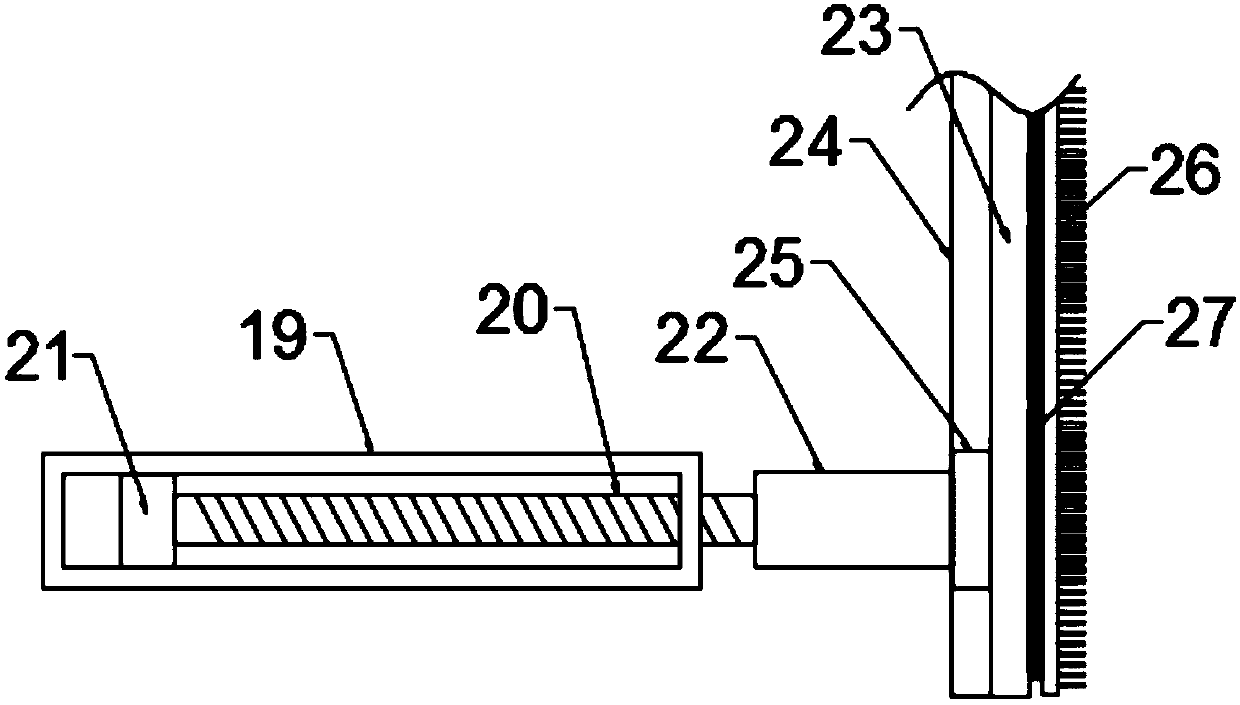

[0025] The difference between this embodiment and Embodiment 1 is that the first stirring rod frame 16 is an assembled structure, which includes two sleeves fixedly connected to the side walls of the first rotating sleeve 7 and the second rotating sleeve 14 respectively. The pipe 19 and the outer ends of the two casing pipes 19 are connected with the same vertical lever 23 through the adjustment mechanism, and the side wall of the vertical lever 23 is provided with a sliding card slot 24, and the inner side of the sliding card slot 24 is provided with a connection for sliding connection therewith. The slider 25, the connecting slider 25 is connected to the outer end of the sleeve 19, and the side wall of the vertical lever 23 away from the sleeve 19 is connected with a cleaning device for cleaning the inner wall of the mixing cylinder 1 through a Velcro 27. Brush 26, the adjustment mechanism includes a screw rod 20 inserted through the inside of the sleeve 19 and screwed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com