Piece arranging device for high-speed notching press

A high-speed punching and slotting machine technology, which is applied to the feeding device, positioning device, storage device, etc., can solve the problems of harsh working environment, monotonous machinery, poor safety, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

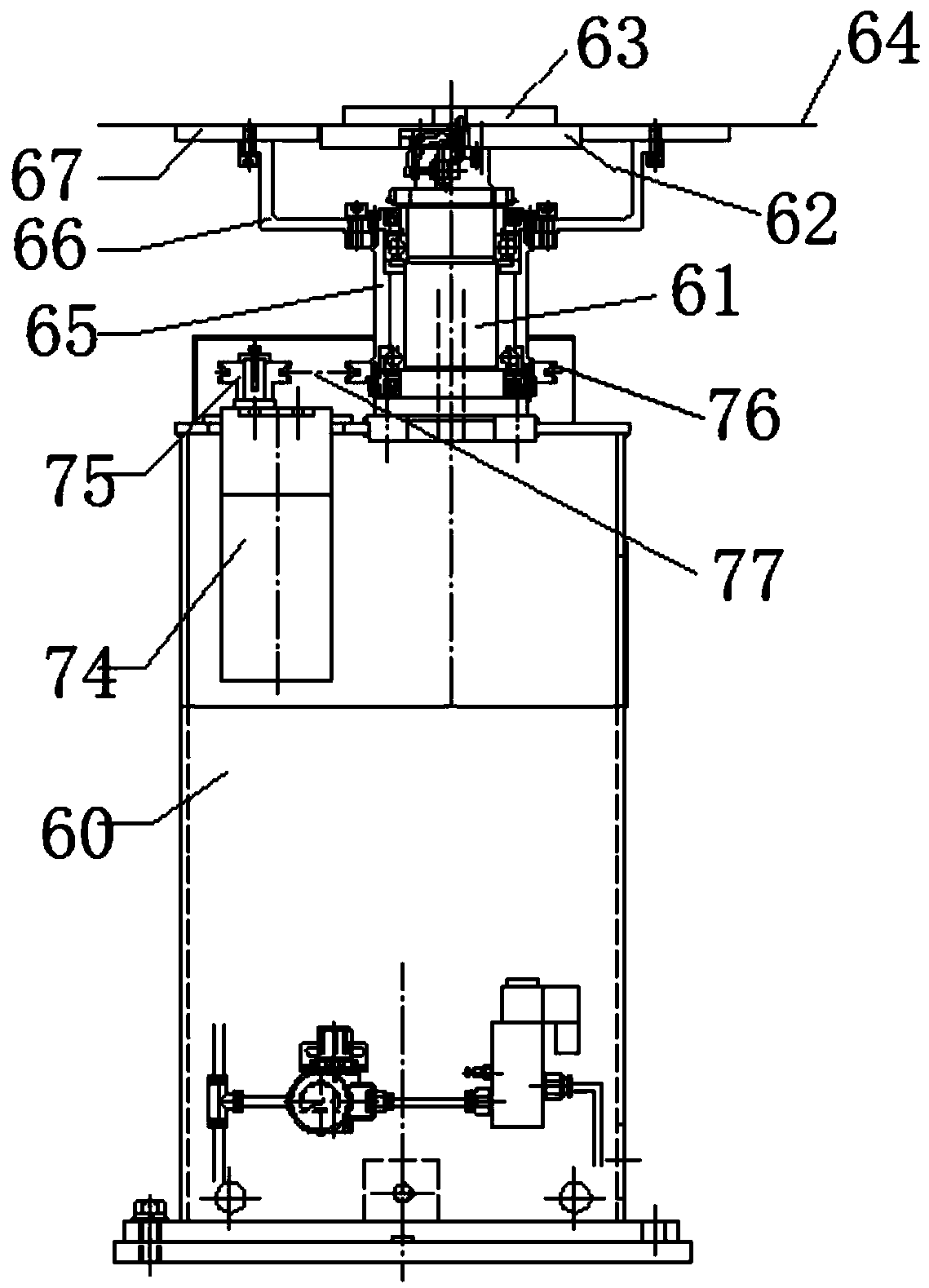

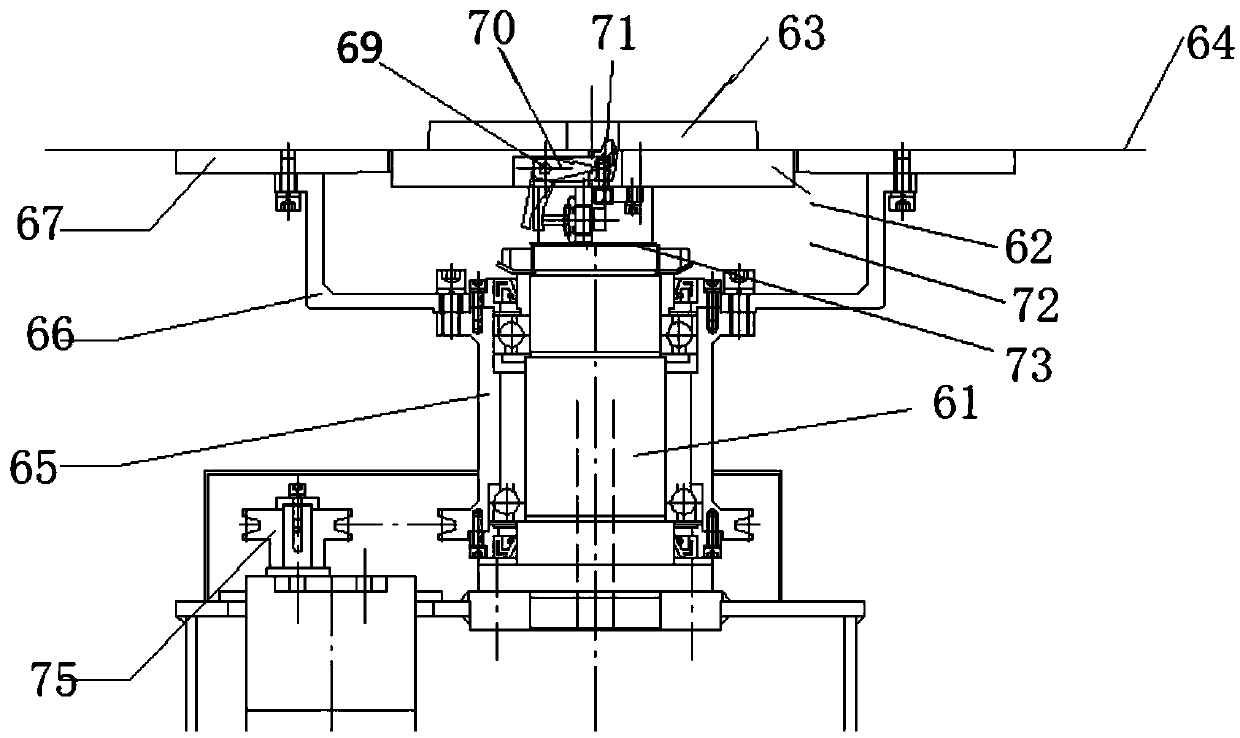

[0020] See attached picture.

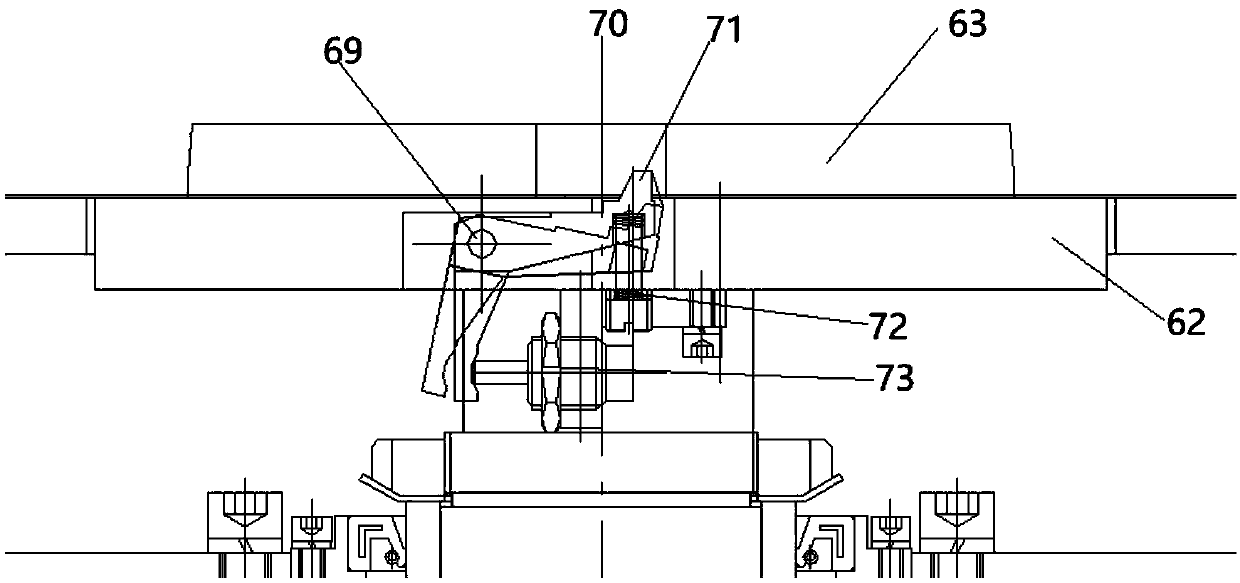

[0021] A sorting device for a high-speed notching machine includes a frame 60, the top of the frame 60 is fixed with a longitudinal central fixed shaft 61, the top of the central fixed shaft 61 is fixed with a round block 62, and the upper surface of the round block 62 is fixed with a positioning Disk 63, the diameter size of positioning disk 63 is matched with the diameter size of motor blank sheet 25 center hole; Center fixed shaft 61 outer rotation sleeve is provided with rotating sleeve 65, and the annular top surface of rotating sleeve 65 is fixed with cylindrical rotating disk 66, and rotating disk The ring-shaped top surface of 66 is fixed with the rotary disc 67 that is sleeved on the outside of the round block 62, which is clearance fit between the said rotary disc 67 and the round block 62; Motor blank sheet 25 ; a lever positioning mechanism is installed on the round block 62 .

[0022] The lever positioning mechanism includes a lever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com