Waste plastic regenerating system with iron removal function

A technology of waste plastics and regeneration system, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems affecting production safety, endangering people's health, damaging the environment, etc., and achieve the effect of normal feeding and avoiding floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

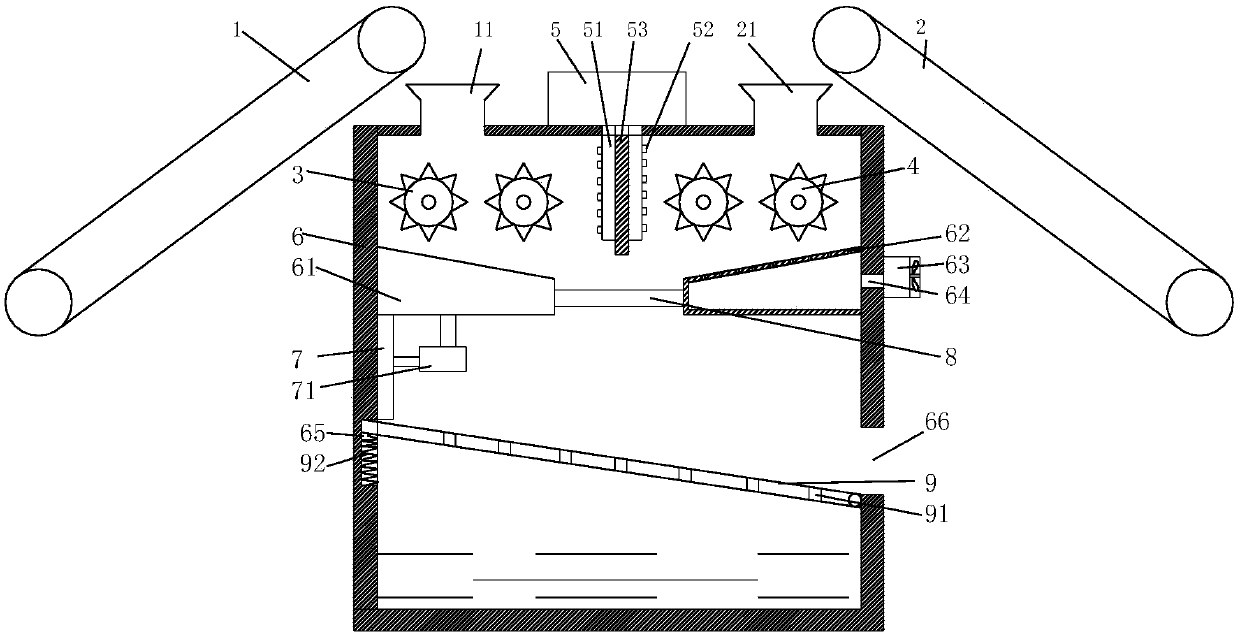

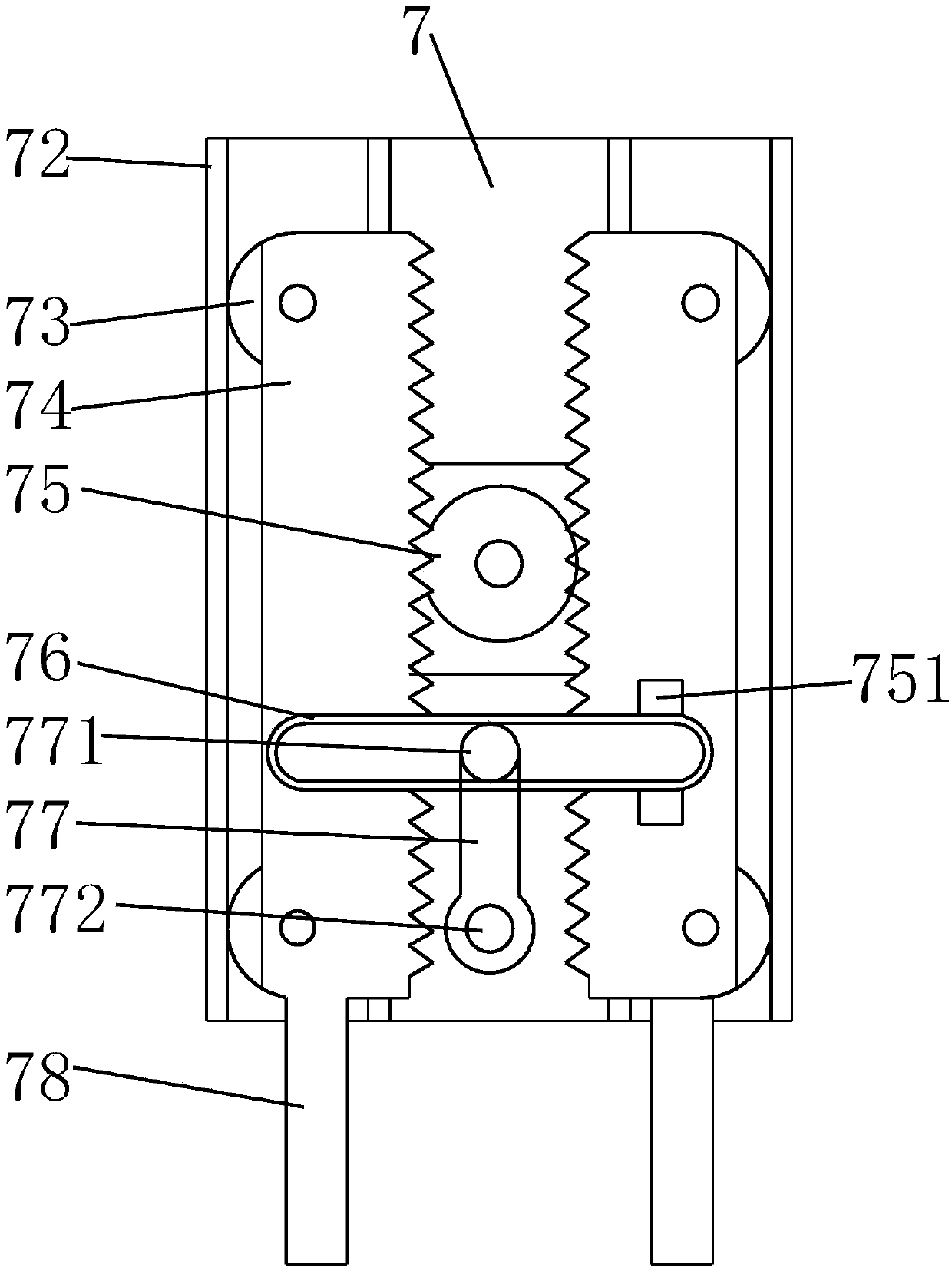

[0018] Such as Figure 1 to Figure 5 As shown, the present invention provides a waste plastic regeneration system with iron removal function, comprising a box body 6, a first feed port 11 and a second feed port 21 respectively arranged at both ends of the top of the box body 6, the first feed port A first conveyor belt 1 and a second conveyor belt 2 are provided above the port 11 and the first feed port 21, respectively, and a second conveyor belt 1 and a second conveyor belt 2 are respectively provided below the first feed port 11 and the second feed port 21 in the box body 6. One pulverizing roller 3, the second pulverizing roller 4;

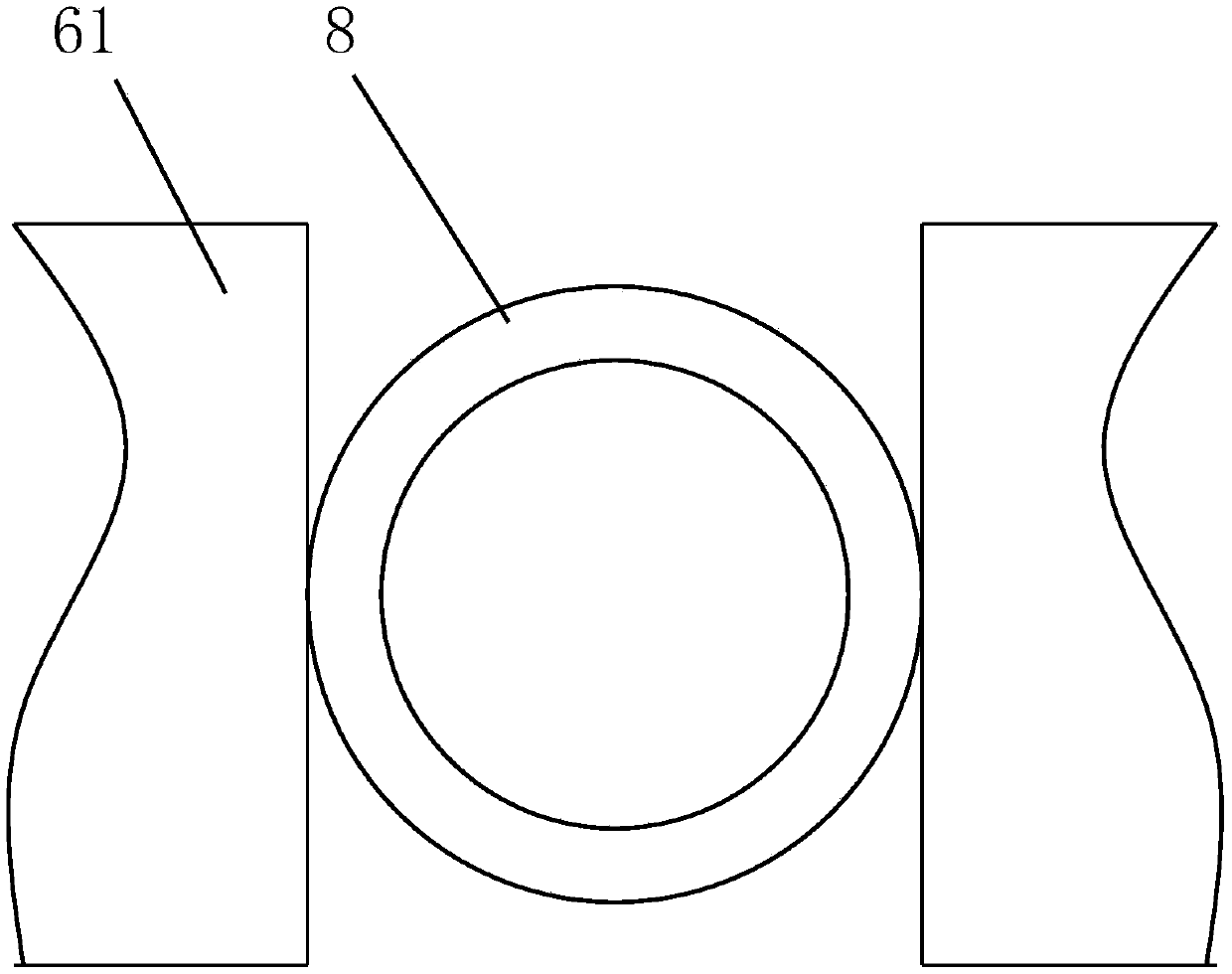

[0019] Partition plate 53 is provided between the first crushing roller 3 and the first crushing roller 4, and the bottom of the first crushing roller 3 and the first crushing roller 4 is provided with a material guide box 61, and the inner wall between the material guide box 61 is fixed. There is a circular ferromagnet 8, the middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com