Mould for floor sewer line reserved hole

A technology for molding molds and reserved holes, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., and can solve problems such as insufficient strength, low reuse rate, and greater impact on project progress and quality. problem, achieve the effect of ensuring verticality and avoiding floating displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

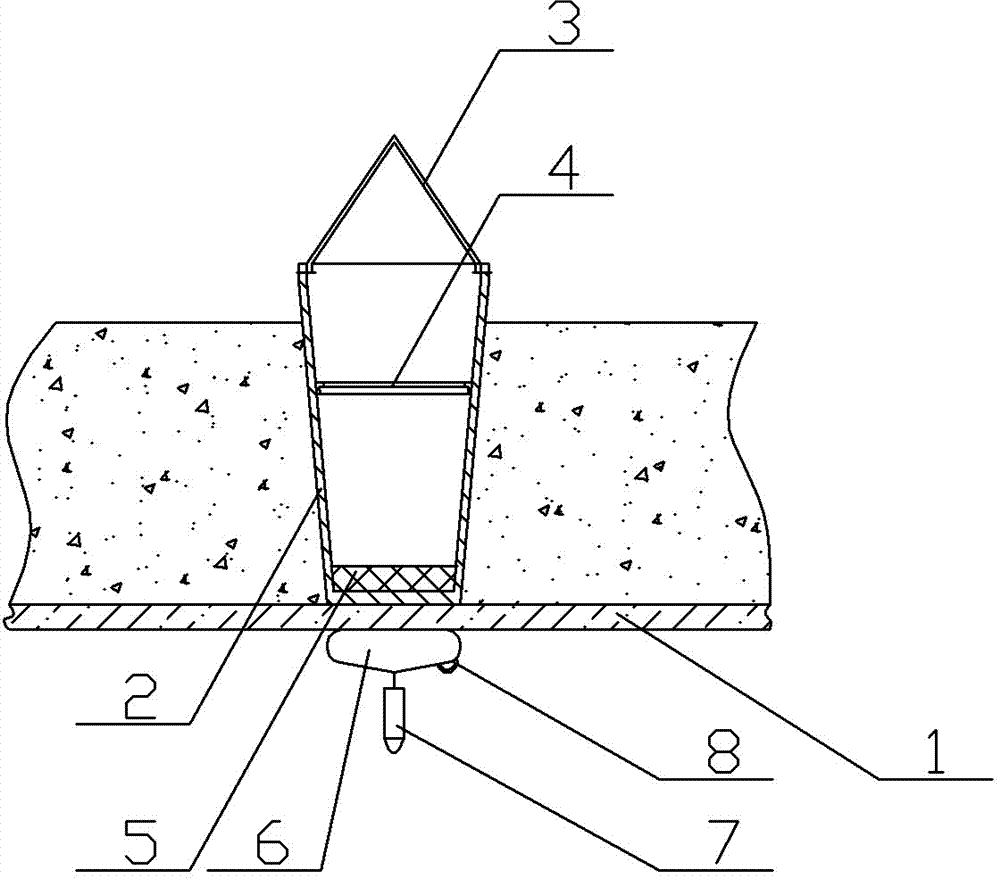

[0011] like figure 1 As shown, the present invention provides a mold for forming reserved holes for floor sewer pipes, which includes a frustum-shaped metal barrel 2 placed above the floor template 1 and a handle 3 fixed on the upper part of the metal barrel 2. The contact area between the handle 3 and the hand is It can be as large as possible, and the material can be metal strips or ropes. It is mainly for the convenience of drafting. The inner wall of the metal barrel body 2 is welded with a circle of metal ring-shaped ribs 4. The cross-section of the metal ring-shaped ribs 4 is L-shaped. Increase the strength of the metal barrel 2 to avoid deformation during pouring of concrete or daily extrusion and bumping, thereby ensuring the regularity of the holes in the metal barrel 2. The upper opening area of the metal barrel 2 should be la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com