Rapid-hardening microswelling curing agent, cured soil and preparation method therefor

A technology for micro-expansion and solidification of soil, which is applied in the field of rapid-hardening micro-expansion type curing agent, solidification soil and its preparation. It can solve the problems of high cost and increased sand and gravel consumption, and achieve low engineering cost, saving consumption and good construction performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

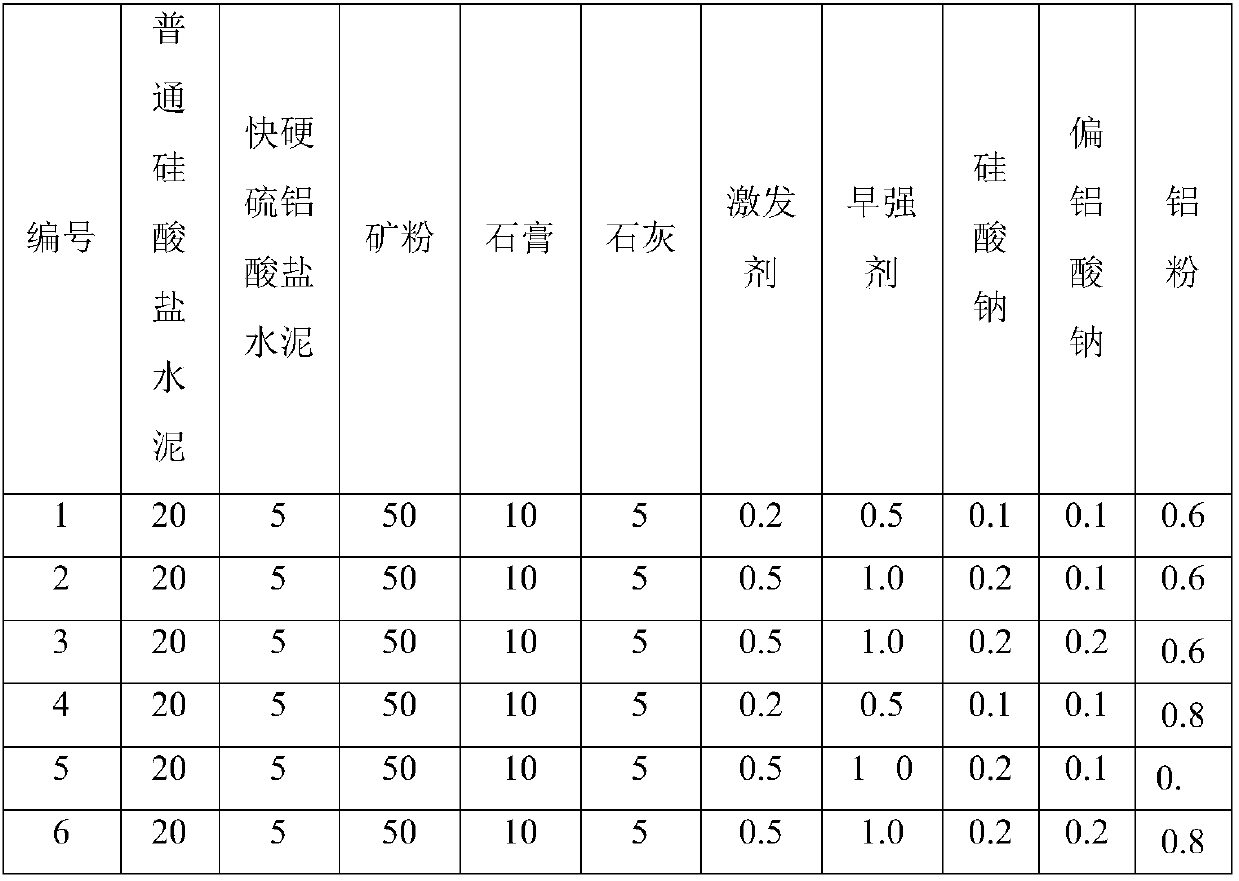

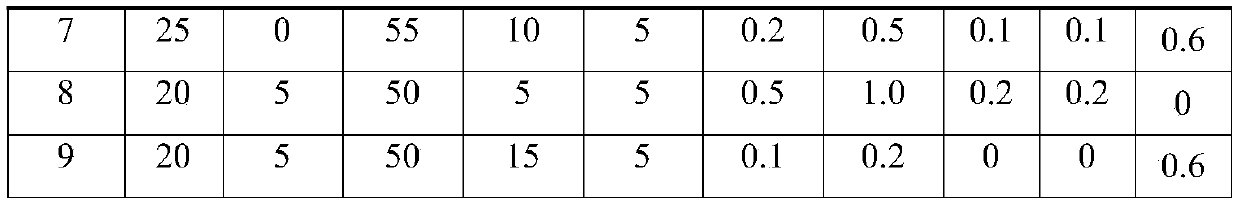

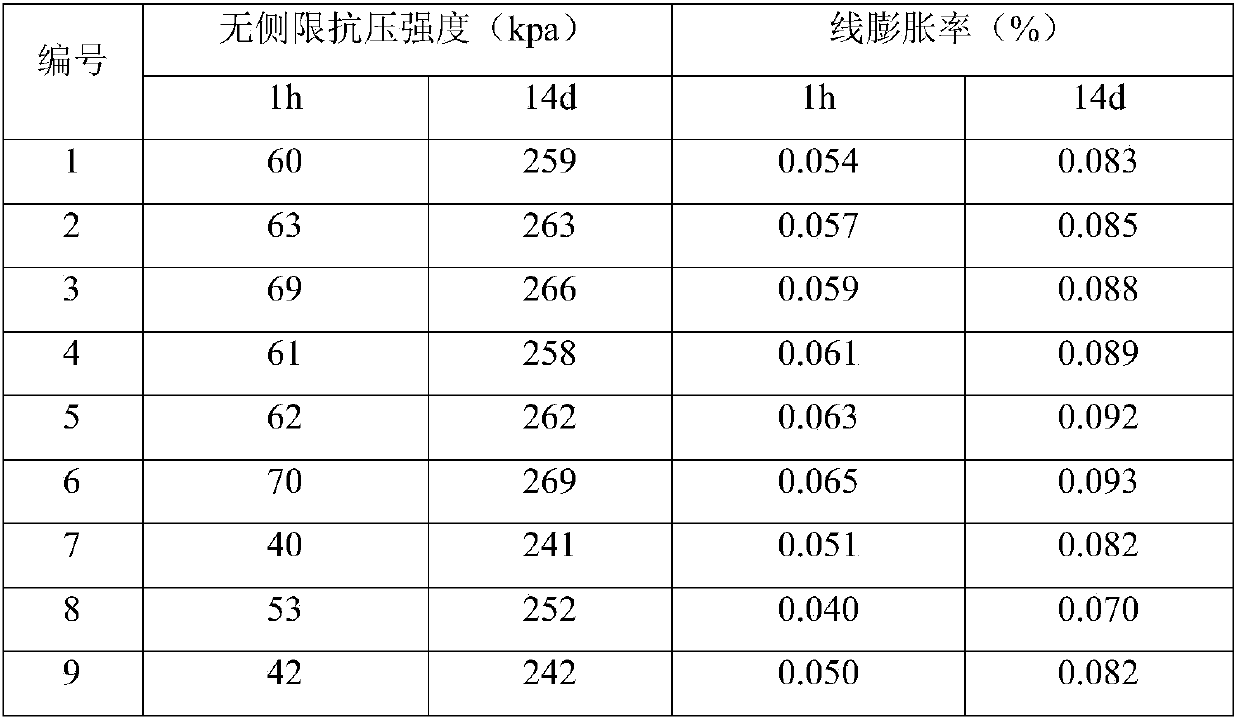

[0037] A quick-hardening and micro-expansion curing agent, comprising the following composition: 20 parts of ordinary Portland cement; 5 parts of quick-hardening sulphoaluminate cement; 50 parts of mineral powder; 10 parts of gypsum; 5 parts of lime; 0.5-1.0 parts of early strength agent; 0.1-0.2 parts of sodium silicate; 0.1-0.2 parts of sodium metaaluminate; 0.5-0.8 parts of aluminum powder.

Embodiment 2

[0039] A quick-hardening micro-expansive solidified soil, comprising soil and a solidifying agent, the solidifying agent comprising the following composition: 20 parts of ordinary Portland cement; 5 parts of rapid-hardening sulfoaluminate cement; 50 parts of mineral powder; 10 parts of gypsum ; 5 parts of lime; 0.2-0.5 parts of activator; 0.5-1.0 parts of early strength agent; 0.1-0.2 parts of sodium silicate; 0.1-0.2 parts of sodium metaaluminate;

Embodiment 3

[0041] A method for preparing quick-hardening micro-expansive solidified soil, comprising the steps of,

[0042] 1) Prepare a curing agent capable of quickly hardening the soil and producing swelling. The curing agent formula is: 20 parts of ordinary Portland cement; 5 parts of rapid hardening sulfoaluminate cement; 50 parts of mineral powder; 10 parts of gypsum; 5 parts of lime; 0.2-0.5 parts of stimulating agent; 0.5-1.0 parts of early strength agent; 0.1-0.2 parts of sodium silicate; 0.1-0.2 parts of sodium metaaluminate; 0.6-0.8 parts of aluminum powder.

[0043] 2) It is convenient and easy to take soil locally according to the project requirements;

[0044] 3) uniformly mix the above-mentioned prepared soil curing agent with the soil;

[0045] 4) Fill the mixture into the part to be plugged, and form an integral block with high strength after hardening.

[0046] Wherein step 2) take soil on the spot according to engineering requirement, add sodium carbonate or sodium hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com