Steel-making process material distribution method based on gas analysis

A material distribution and gas technology, which is applied in the field of distribution in the steelmaking process based on gas analysis, can solve the problems of improper feeding timing, splashing, and high material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The embodiment of the present application provides a method for distributing materials in the steelmaking process based on gas analysis, including:

[0025] Before charging the converter, ensure the normal operation of the secondary system and the furnace gas analysis system. After the charging is completed, the furnace body returns to the zero position, and the lowering gun blowing begins.

[0026] Calculate the total amount of lime, dolomite, and ore that needs to be input in the steelmaking process.

[0027] Measuring O in Furnace Gas Using Furnace Gas Analysis System 2 , CO, CO 2 content value, and the measured O 2 , CO, CO 2 The content value is fed back to the secondary control system.

[0028] The furnace gas is the furnace gas that has been sprayed and cooled after being extracted by the furnace gas analysis system from the outlet of the converter flue evaporative cooler. Specifically, the furnace gas is extracted from the exit position of the converter flu...

Embodiment 2

[0041] The embodiment of the present application provides a method for distributing materials in the steelmaking process based on gas analysis, including:

[0042] Before charging the converter, ensure the normal operation of the secondary system and the furnace gas analysis system. After the charging is completed, the furnace body returns to the zero position, and the lowering gun blowing begins.

[0043] Calculate the total amount of lime, dolomite, and ore that needs to be input in the steelmaking process.

[0044] Measuring O in Furnace Gas Using Furnace Gas Analysis System 2 , CO, CO 2 content value, and the measured O 2 , CO, CO 2 The content value is fed back to the secondary control system.

[0045] When O in the furnace gas 2 When the CO content is 12% to 18% and the CO content is 6% to 10%, the secondary control system controls the first feeding, which includes lime, dolomite and ore, wherein the lime is the lime 65% of the total amount, dolomite is 100% of the...

Embodiment 3

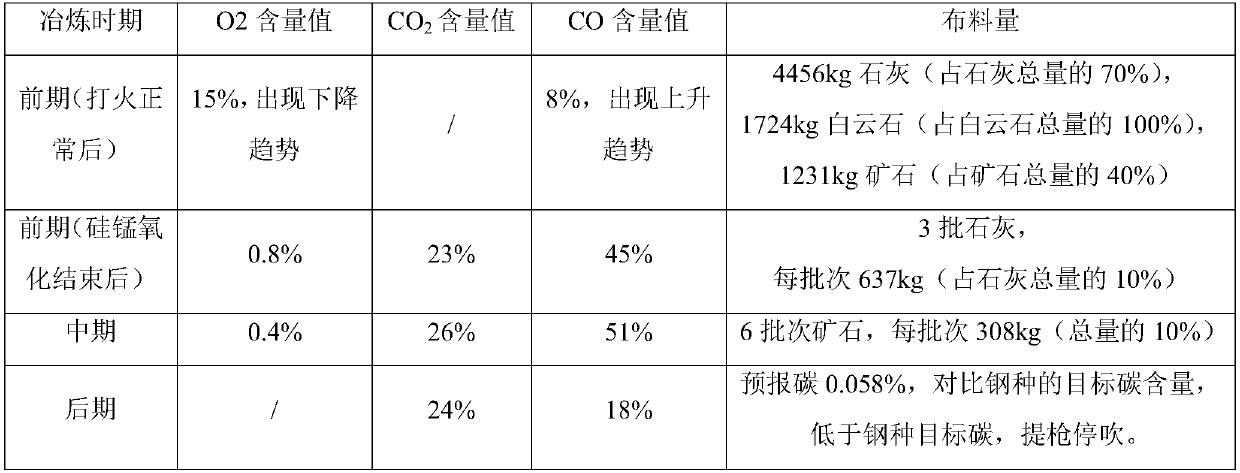

[0050] As shown in Table 1, taking the smelting of Q345R and the target carbon content of 0.06% as an example, the distribution control of the converter is as follows:

[0051] After calculation, the total amount of lime is 6367kg, the total amount of dolomite is 1724kg, and the total amount of ore is 3077kg;

[0052] Table 1 Taking the smelting of Q345R and the target carbon of 0.06% as an example, the distribution control of the converter

[0053]

[0054] To sum up, this application provides a method for distributing material in the steelmaking process based on gas analysis, including: calculating the total amount of lime, dolomite, and ore required in the steelmaking process; using the furnace gas analysis system to measure the furnace O in the air 2 , CO, CO 2 content value, and the measured O 2 , CO, CO 2 The content value is fed back to the secondary control system; the secondary control system receives O in the furnace gas 2 , CO, CO 2 content information, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com