A method for controlling carburization of metallographic structure of bg801 material

A technology of metallographic structure and control method, which is applied in the field of carburizing control of BG801 material metallographic structure, can solve the problems of unqualified metallographic structure and failure to meet the design process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

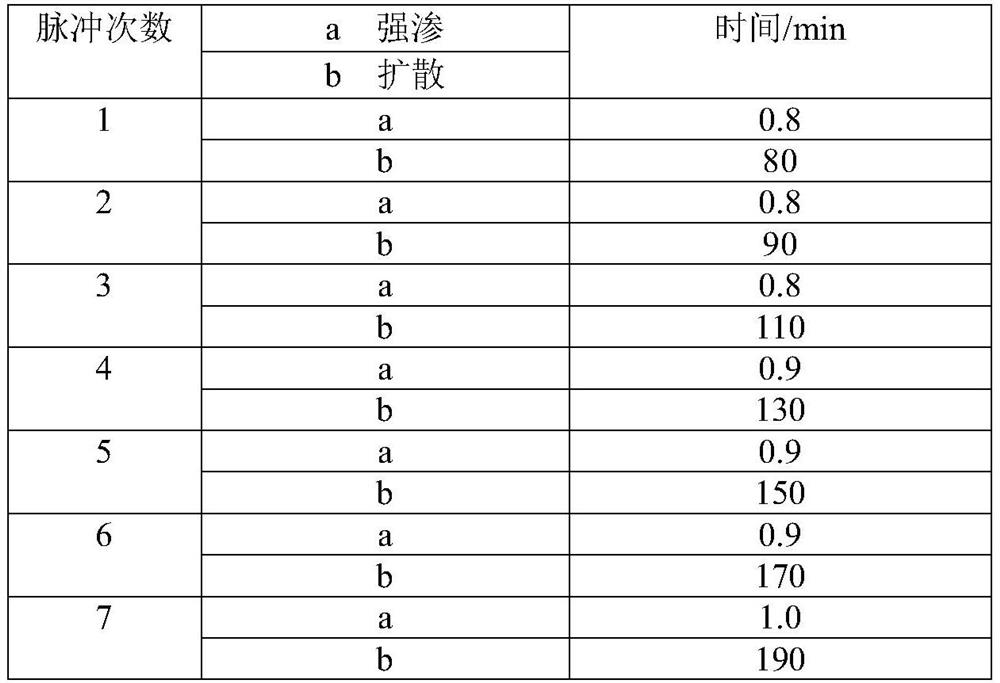

[0016] The depth of the carburized layer of BG801 material is required to be 0.70-0.90mm, the carburizing process temperature is 980°C, the supply of acetylene is 1200L / h, and N can be supplied in the pulse diffusion stage. 2 , supply N 2 When the flow rate is 1500L / h, the adjustment process system of the pulse parameters is shown in Table 1 below.

[0017] Table 1 Low pressure vacuum carburizing pulse parameter list

[0018]

[0019] After performing this process, after 1060°C quenching + -70°C ice cooling + 500°C aging + -190°C deep cooling + 500°C secondary aging, the penetration layer depth from microhardness to Vickers hardness HV580 is 0.89mm, and the metallographic structure There is no primary carbide precipitated in the Widmanstatten structure, which meets the design requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com