Fin enhanced heat exchange infrared suppressor and infrared suppression method

A technology of infrared suppression and enhanced heat transfer, which is applied to the cooling of machines/engines, jet propulsion devices, turbines/propulsion devices, etc. It can solve the problems of complex exhaust system structure and increased aircraft weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

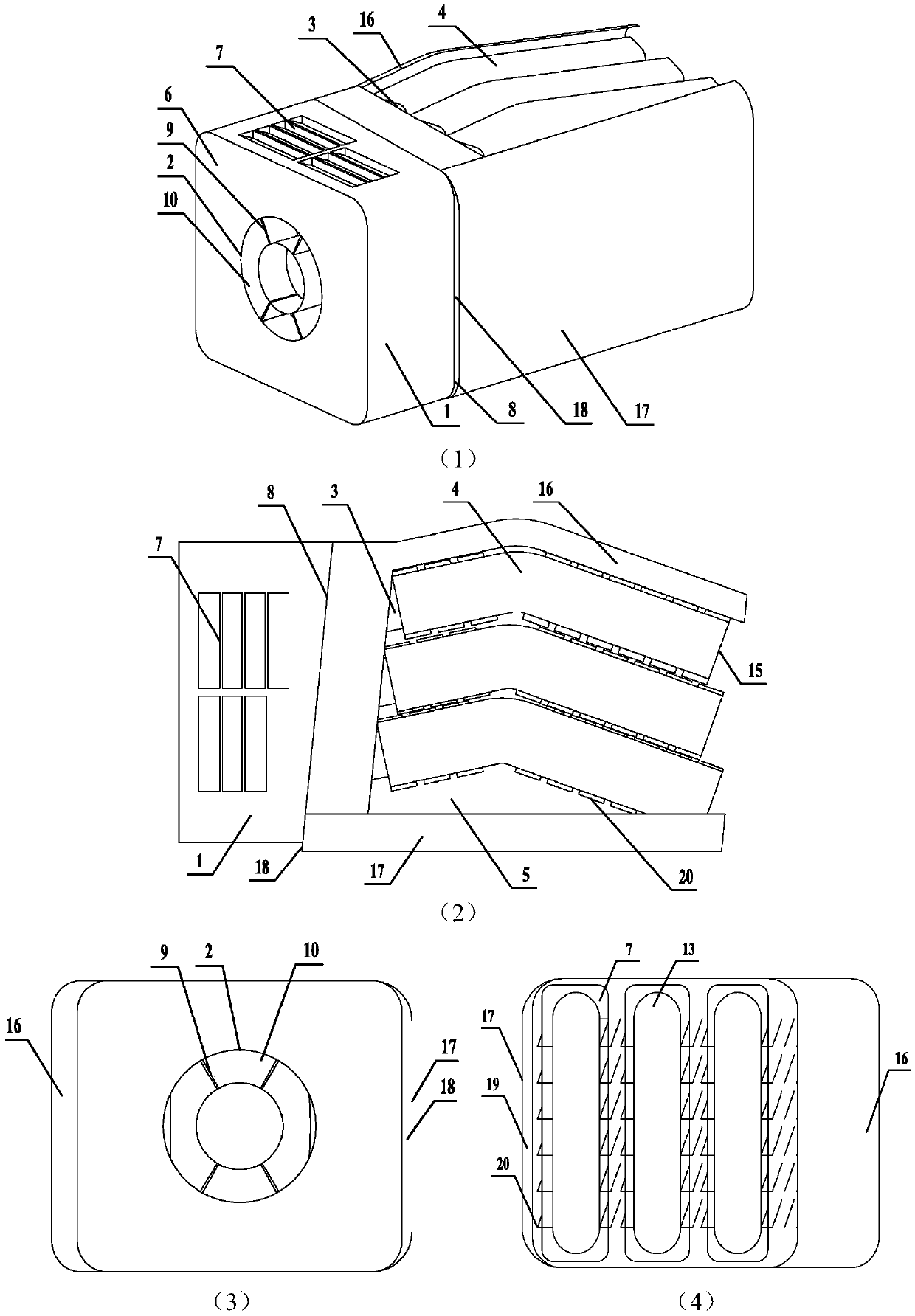

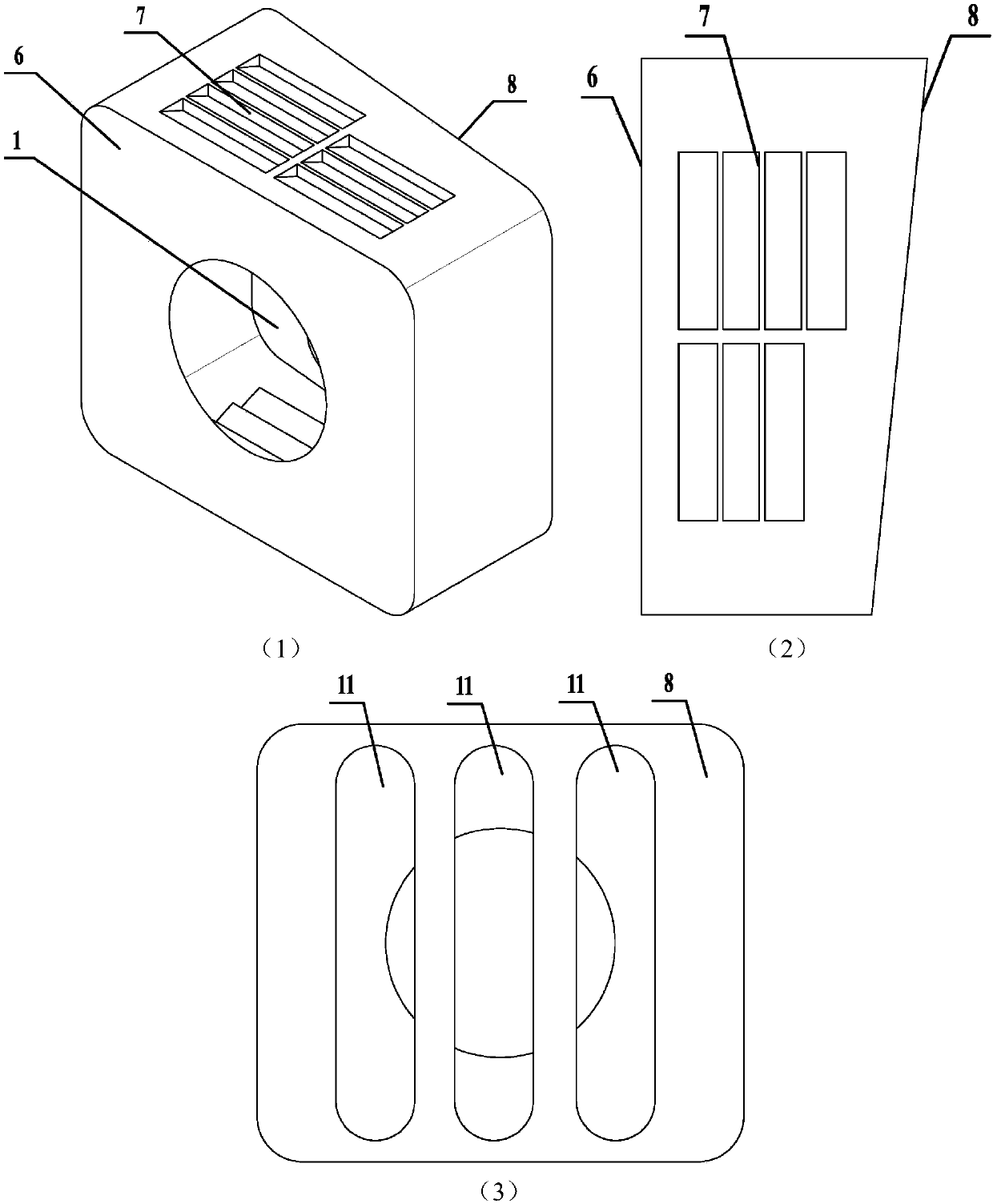

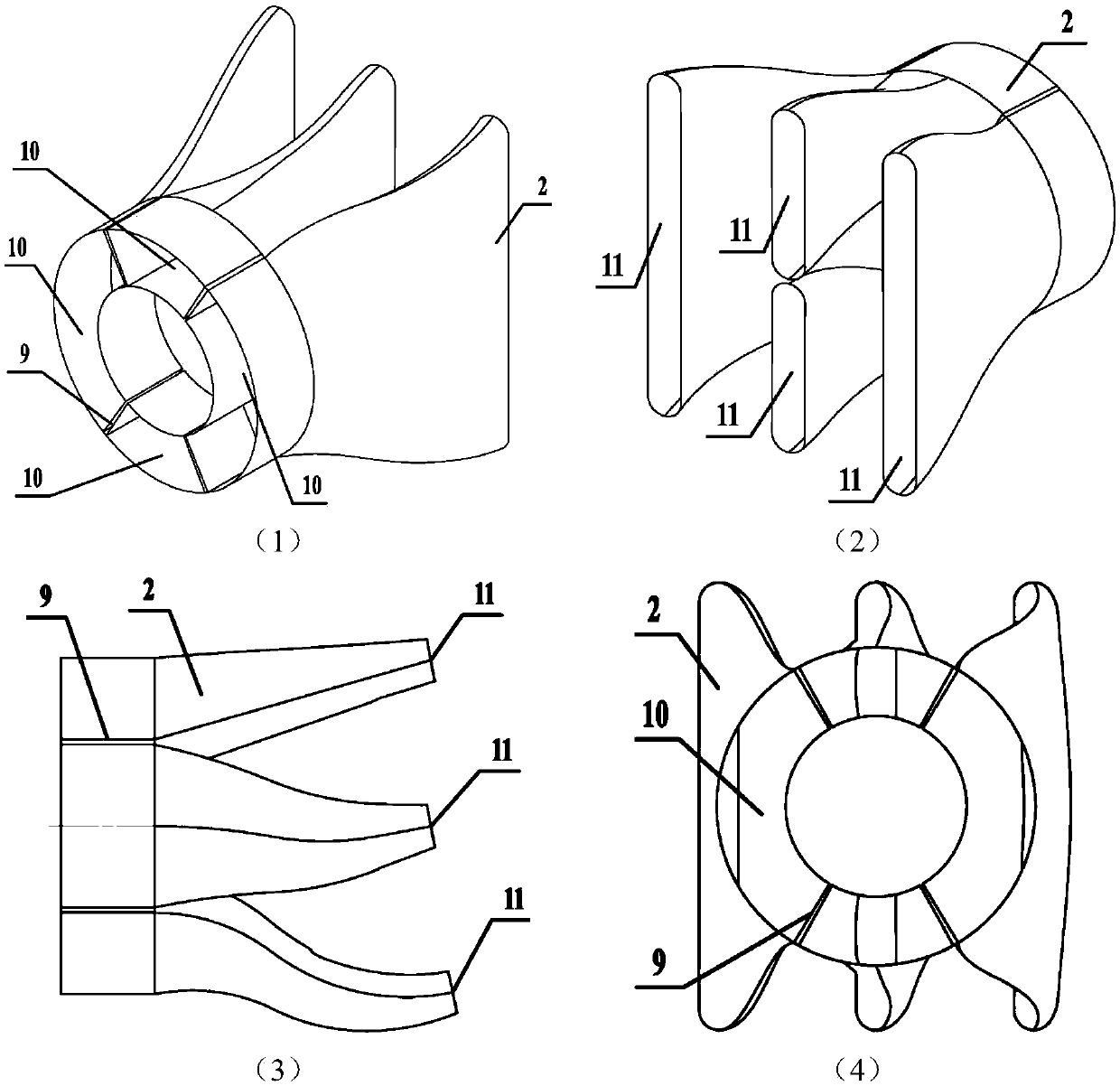

[0035] Please refer to Figure 1 to Figure 6 As shown, the fin-enhanced heat exchange multi-split infrared suppressor of the present invention includes a gas collection chamber 1, a multi-split nozzle 2, a mixing tube 3, a heat shield 4, and a heat exchange enhanced chamber 5.

[0036]The air-collecting chamber 3 is a cavity formed by a firewall 6, a baffle plate 8, and a side wall. The enhanced heat exchange cavity 5 is a cavity composed of skins on both sides and bottom. At the center of the plane where the firewall 6 is located, there are multiple air inlets 10 for the diverging nozzles, and the air inlets 10 for the multi-firing nozzles are annular. There are cold air inlets 7 on the upper and lower walls of the air collection chamber 1; the baffle plate 8 is the interface between the air collection chamber 1 and the enhanced heat exchange chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com