Magnetic suspension air blower impeller and spindle connecting structure

A blower and magnetic levitation technology, which is applied to the components of the pumping device for elastic fluid, mechanical equipment, non-variable-capacity pumps, etc. State, novel structure design, effect of strong shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

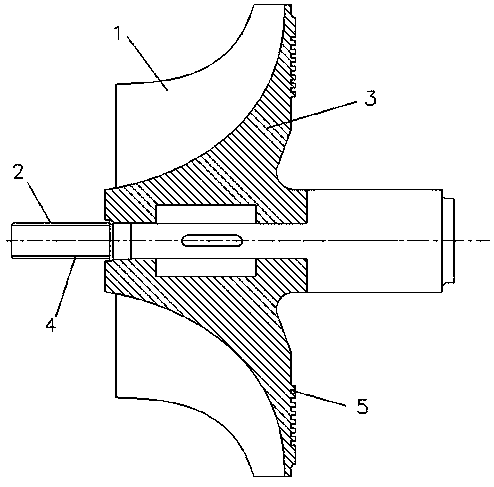

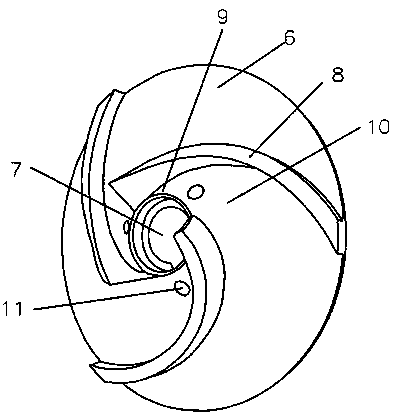

[0024] see figure 1 , the present invention provides a technical solution: a connection form between the impeller and the main shaft of a magnetic levitation blower, including an impeller 1, a motor shaft 2 and a diversion cap 3, the center of the impeller 1 is provided with a shaft hole, and the motor shaft 2 and the The pull rod forms an integrated structure, the motor shaft 2 is connected to the impeller 1 through the shaft hole, and the motor shaft 2 and the impeller 1 are connected through the impeller lock nut 4, the impeller lock nut 4 adopts a circumferential key, and the front end of the impeller 1 A diversion cap 3 is also provided, and a plurality of diversion grooves 5 are evenly distributed on the outer wall of the diversion cap 3 .

[0025] In the present invention, the diversion groove 5 has a U-shaped structure, the width of the diversion groove 5 is 10mm-20mm, and the depth is 5mm-8mm. The diversion groove adopted by the invention can evenly distribute the ai...

Embodiment 2

[0028] Embodiment two:

[0029] see Figure 1-2 , a connection form between the impeller and the main shaft of a magnetic levitation blower, including an impeller 1, a motor shaft 2 and a deflector cap 3, the center of the impeller 1 is provided with a shaft hole, and the motor shaft 2 and the tie rod form an integrated structure. The motor shaft 2 is connected to the impeller 1 through the shaft hole, and the motor shaft 2 and the impeller 1 are connected through the impeller lock nut 4, the impeller lock nut 4 adopts a circumferential key, and the front end of the impeller 1 is also provided with a diversion cap 3, A plurality of diversion grooves 5 are evenly distributed on the outer wall of the diversion cap 3 .

[0030] In the present invention, the diversion groove 5 has a U-shaped structure, the width of the diversion groove 5 is 10mm-20mm, and the depth is 5mm-8mm. The diversion groove adopted by the invention can evenly distribute the airflow field, thereby improvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com