Two-way pressure relief valve

A technology of pressure relief valve and pressure relief valve, which is used in safety valve, balance valve, valve device and other directions, can solve the problems of difficulty in satisfying pressure relief capacity, inconvenient performance adjustment, slow pressure relief protection, etc., to achieve wide applicability, Simple structure, smooth water hammer pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following describes the present invention in detail with reference to the drawings and specific embodiments.

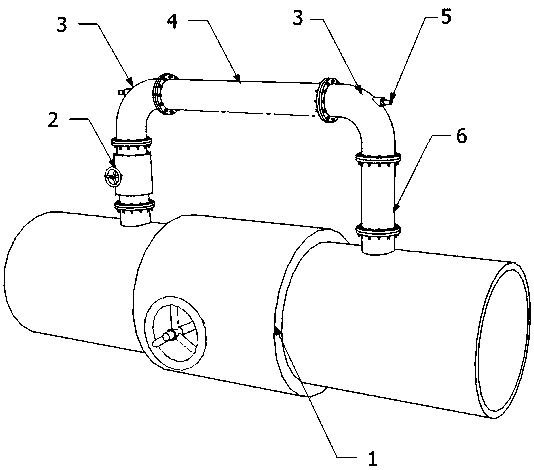

[0024] Such as figure 1 As shown, a two-way pressure relief valve of the present invention has a series branch valve 2 and a branch pipe 6 of a pressure reducing chamber 4 connected in parallel at both ends of the main valve 1 of the main pipeline.

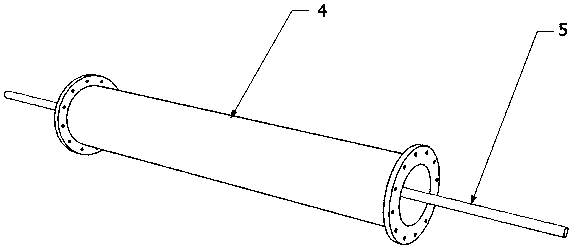

[0025] The decompression chamber 4 in this embodiment is a section of the branch pipeline 6 and is arranged in parallel with the main pipeline; the two ends of the decompression chamber 4 are vertically connected to the main pipeline through the elbow 3, and the branch valve 2 is connected in series on the vertical pipeline .

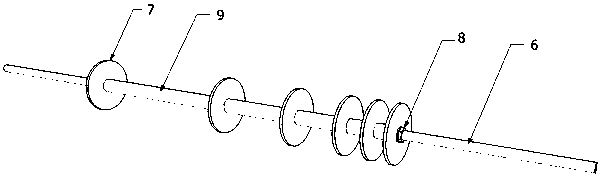

[0026] A coaxial screw 5 is provided in the cavity of the decompression bin 4, and the two ends of the screw 5 are respectively screwed to the screw hole on the elbow 3, and the elbow 3 is exposed, and the screw hole is sealed after screwing.

[0027] A number of pressure-reducing valve plates 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com