Measuring method of tire longitudinal relaxation length

A length measurement, tire technology, applied in the direction of automobile tire testing, etc., can solve the problems of inability to obtain longitudinal slack length and high test cost, and achieve the effect of reducing test workload and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

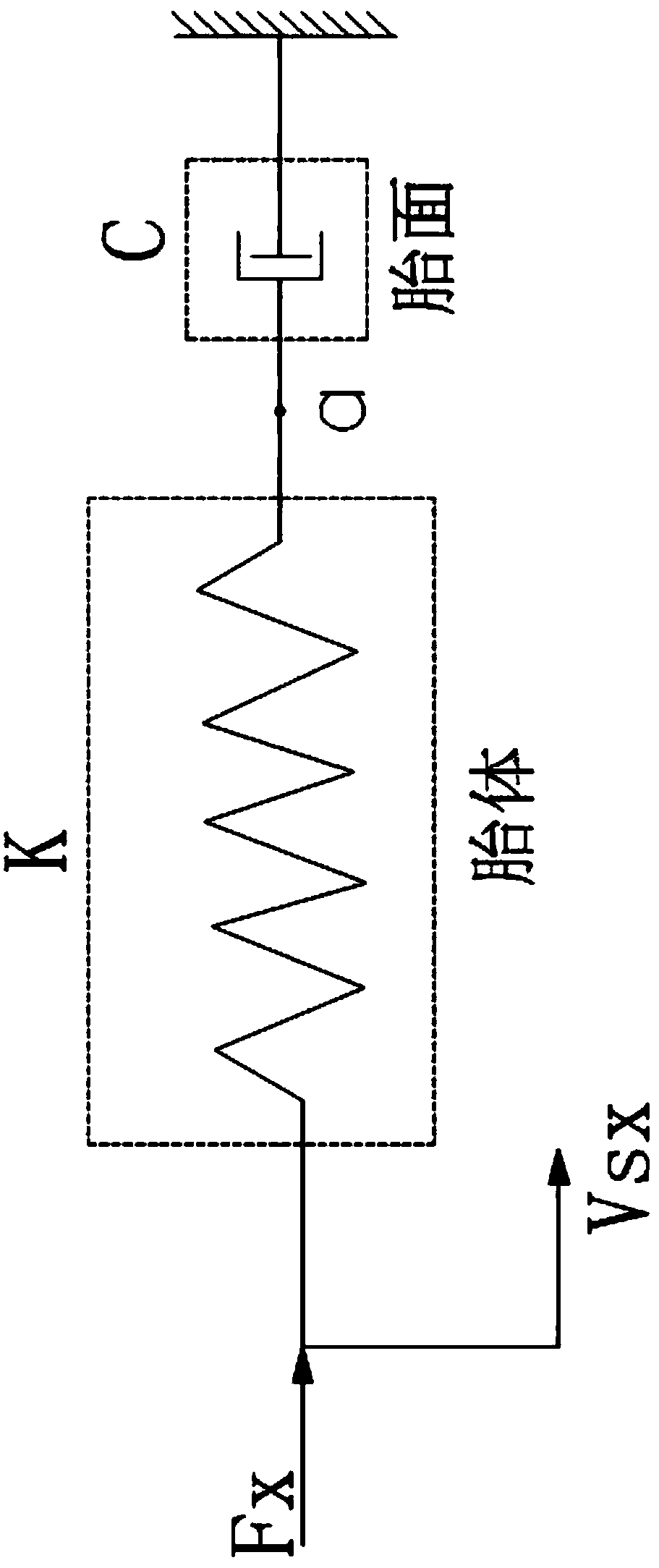

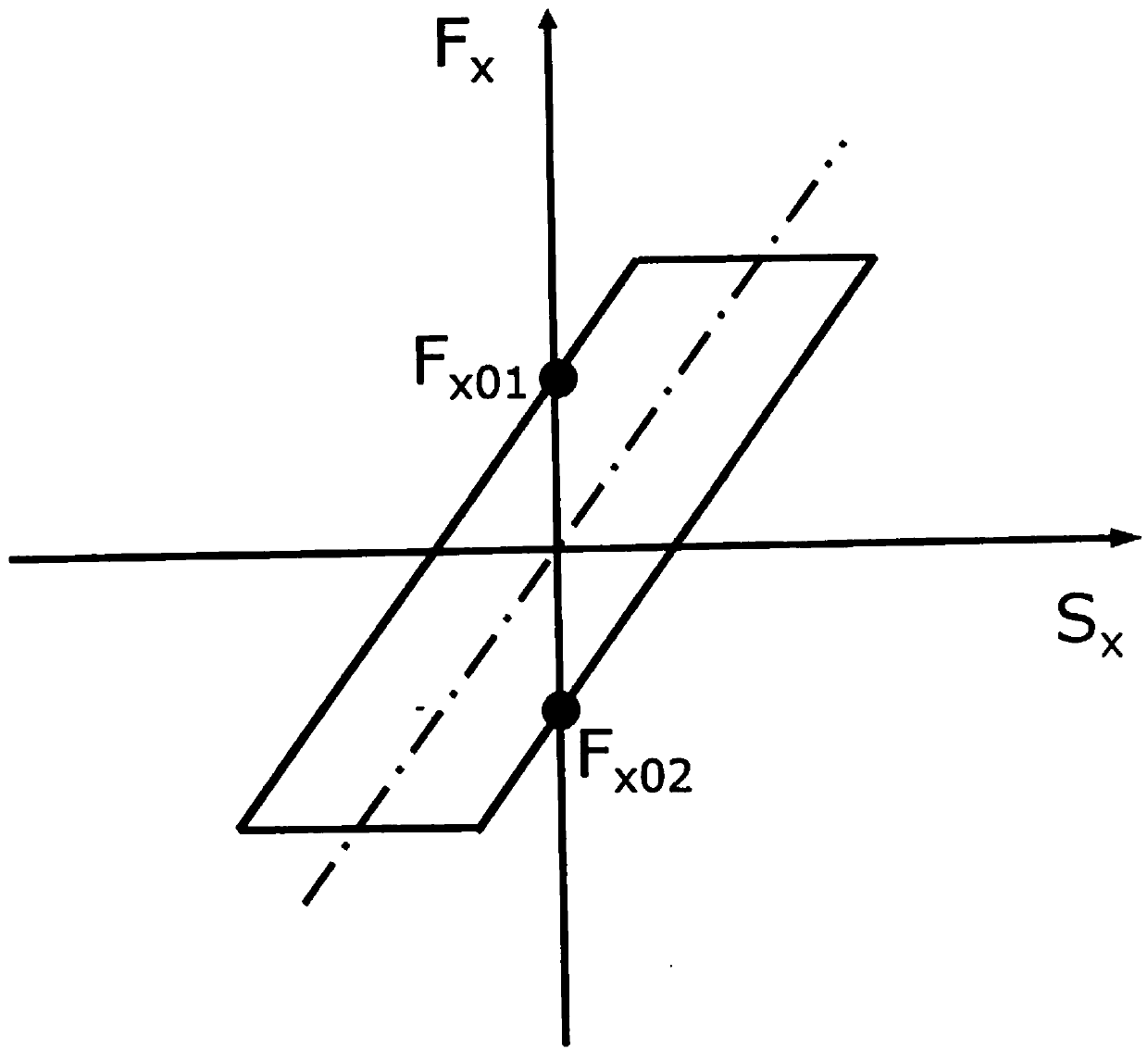

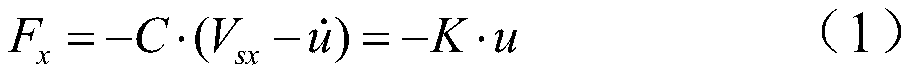

[0020] A method for measuring the longitudinal slack length of a tire, the method is:

[0021] Install the tire on the flat-belt tire six-component force test rig, adjust the side slip angle and roll angle to zero, adjust the flat-belt tire six-component force test rig so that the tire reaches the required vertical load, and the test rig runs at a constant speed Drive the tire to roll, apply the driving and braking torque, control the longitudinal slip rate of the tire, so that the longitudinal slip rate changes according to the set period and amplitude of the triangle wave, obtain the test data of multiple cycles, and perform parameter identification to obtain the longitudinal slack length of the tire , including the following steps:

[0022] 1. Install the test tire on the flat-belt tire six-component force test bench, adjust the roll angle control mechanism of the flat-belt tire six-component force test bench so that the tire roll angle is zero, and adjust the flat-belt tir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap