Signal compensation circuit of pipeline corrosion degree measuring instrument

A technology of signal compensation and corrosion degree, which is applied in the field of signal calibration, can solve the problems of signal distortion, insufficient signal power, affecting the measurement accuracy of pipeline corrosion degree measuring instrument, etc., and achieve the effect of preventing signal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

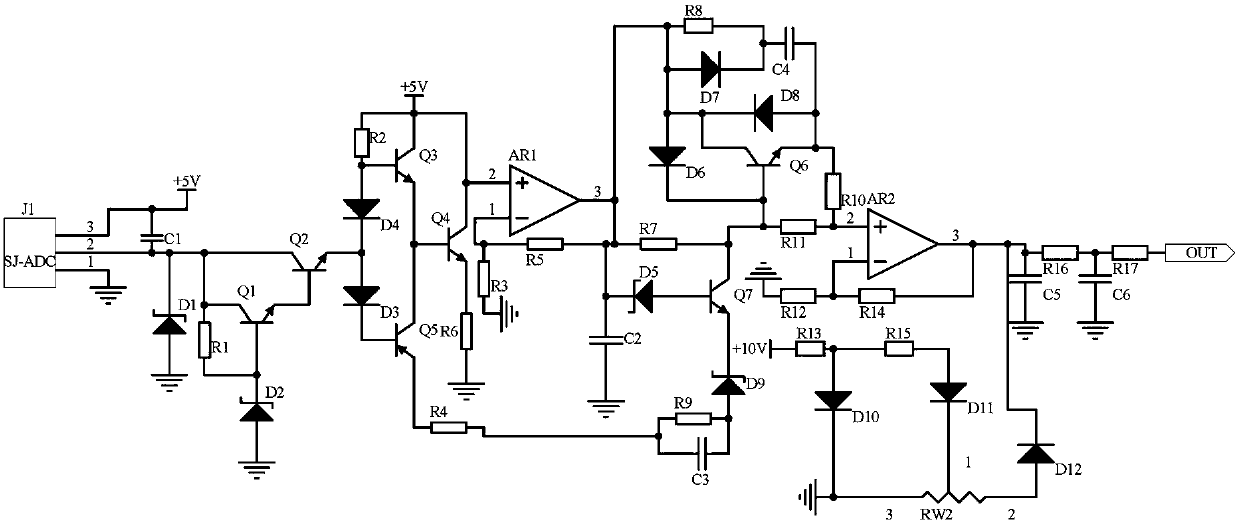

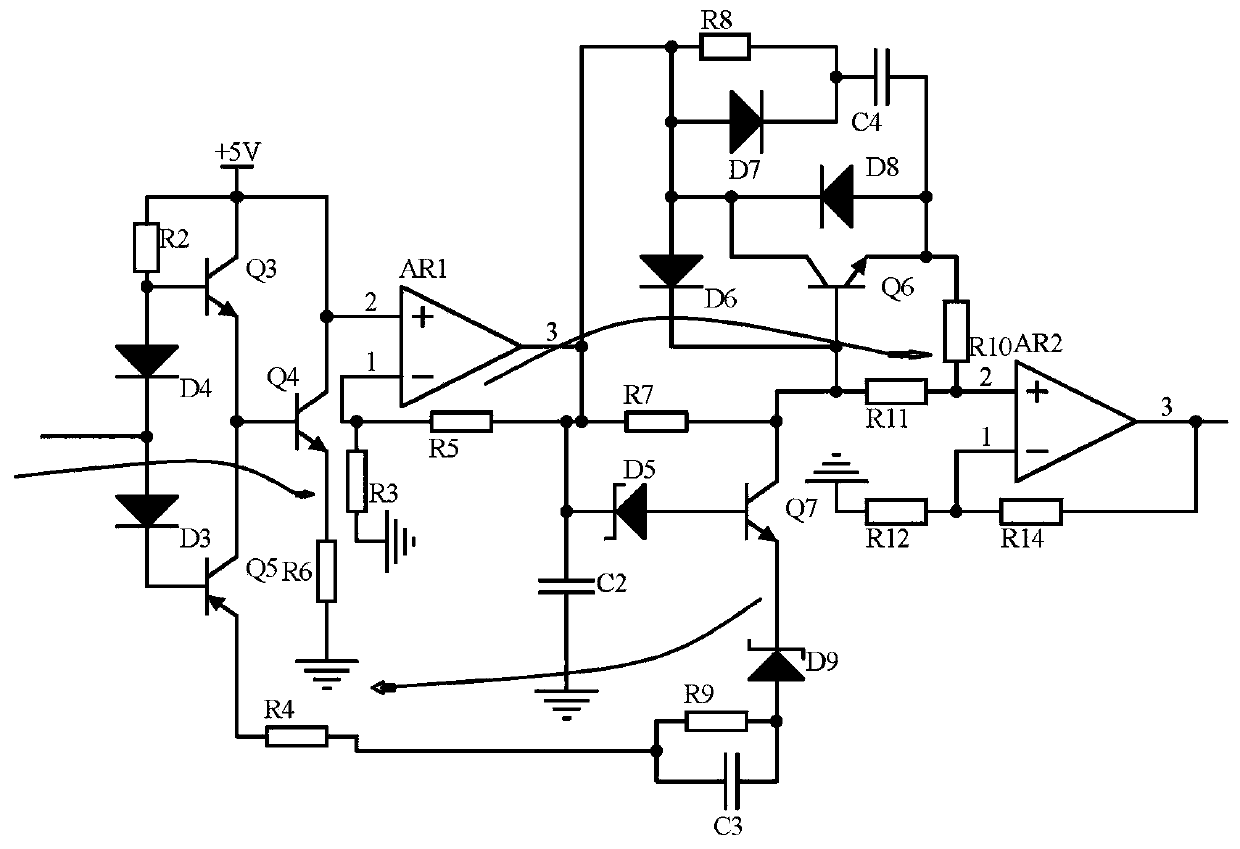

[0015] Embodiment 1. The signal compensation circuit of the pipeline corrosion degree measuring instrument includes a frequency acquisition circuit, a push-pull buffer circuit and a compensation output circuit. The frequency acquisition circuit collects the analog signal frequency when the pipeline corrosion degree measuring instrument is working. The analog signal is the pipeline The corrosion degree measuring instrument controls the signal received by the terminal, and uses the triode Q1 and the triode Q2 to form a switch circuit to isolate the low-level signal. The signal processing circuit not only improves the load capacity of the circuit, but also improves the switching speed. At the same time, the buffer circuit composed of resistor R8, capacitor C4 and transistor Q6 is used to buffer the signal, and the transistor Q7 is used to feed back the output signal of the operational amplifier AR1 to the transistor Q5 for transmission. Pole, adjust the signal conduction value of ...

Embodiment 2

[0017] Embodiment 2. On the basis of Embodiment 1, the compensation output circuit uses the power supply +10V to compensate the output signal of the operational amplifier AR2 after being divided by the variable resistor RW2, and the compensation can be changed by adjusting the resistance potential of the variable resistor RW2. The potential of the signal, because the potential value of the push-pull buffer circuit is not enough to compensate the analog signal when the pipeline corrosion degree measuring instrument is working, so the base potential of the output signal of the operational amplifier AR2 is obtained by using an external power supply +10V and dividing the voltage by the variable resistor RW2. And use resistor R16, resistor R17, capacitor C5, and capacitor C6 to form an RC circuit to filter and output, that is, to compensate the analog signal when the pipeline corrosion degree measuring instrument is working. One end of resistor R16 is connected to one end of capacito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com