Combustion chamber temperature field analysis and adjustment method

An adjustment method and combustion chamber technology, applied in instruments, database management systems, design optimization/simulation, etc., can solve problems such as misjudgment and maintenance cycle, save spare parts funds, reduce tediousness and inefficiency, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

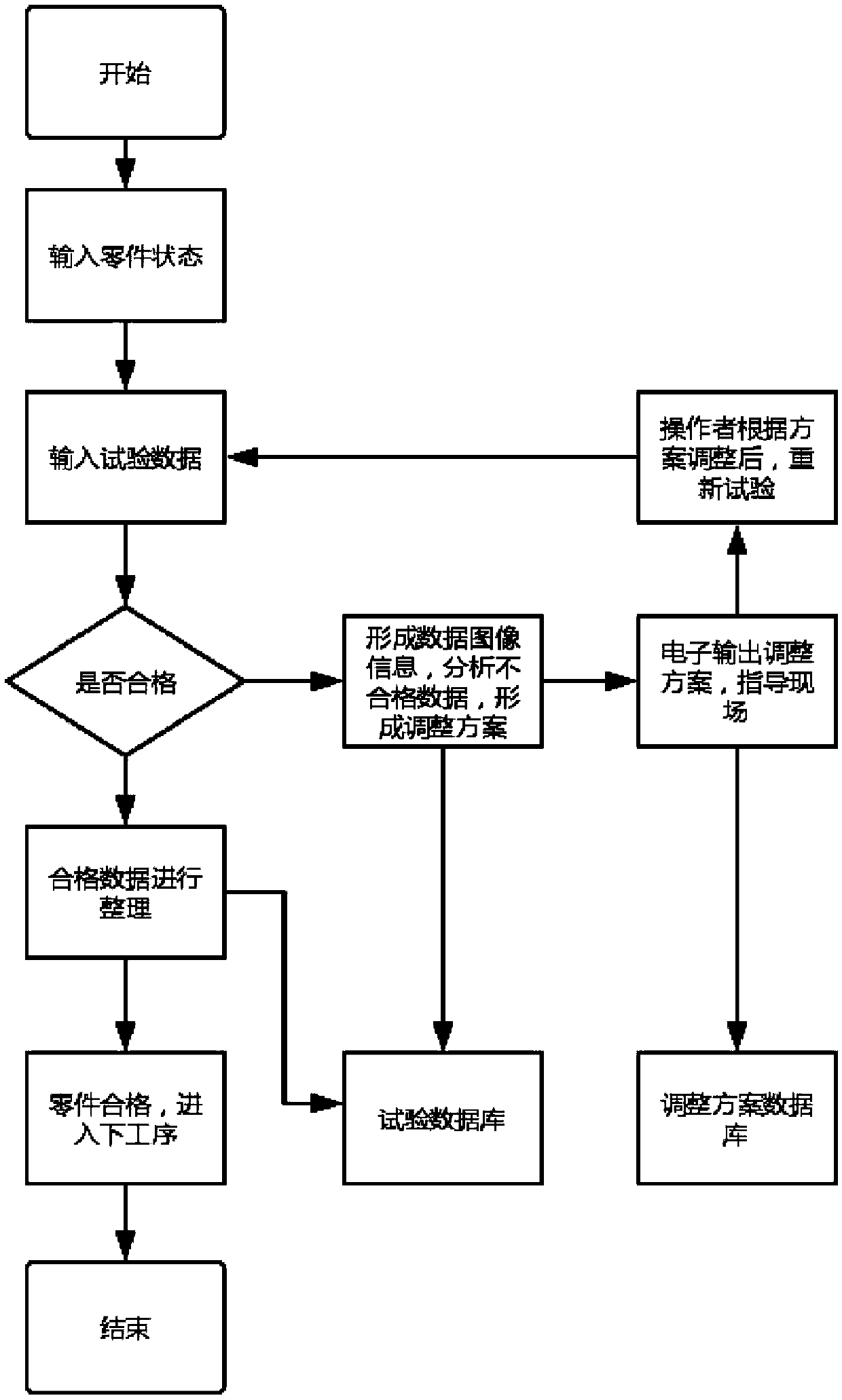

[0045] A combustion chamber temperature field analysis and adjustment method of the present invention is characterized in that it comprises the following steps:

[0046] 1) Data input: convert the basic data, flow data and test result data of a combustion chamber test into associated data sets for storage;

[0047] 2) Data screening: use the basic data, flow data and test result data in the stored data to judge data, and screen out qualified data and unqualified data;

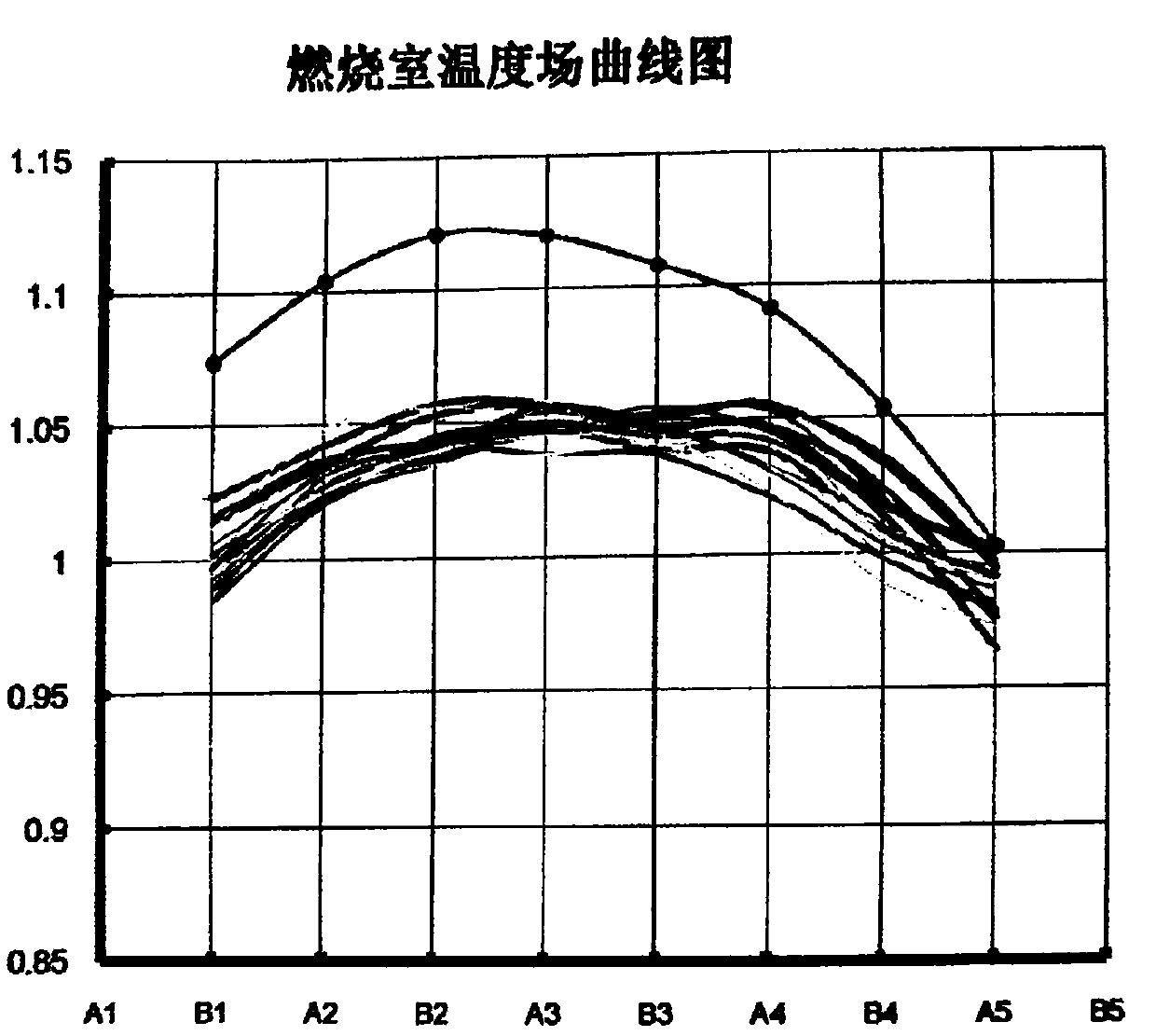

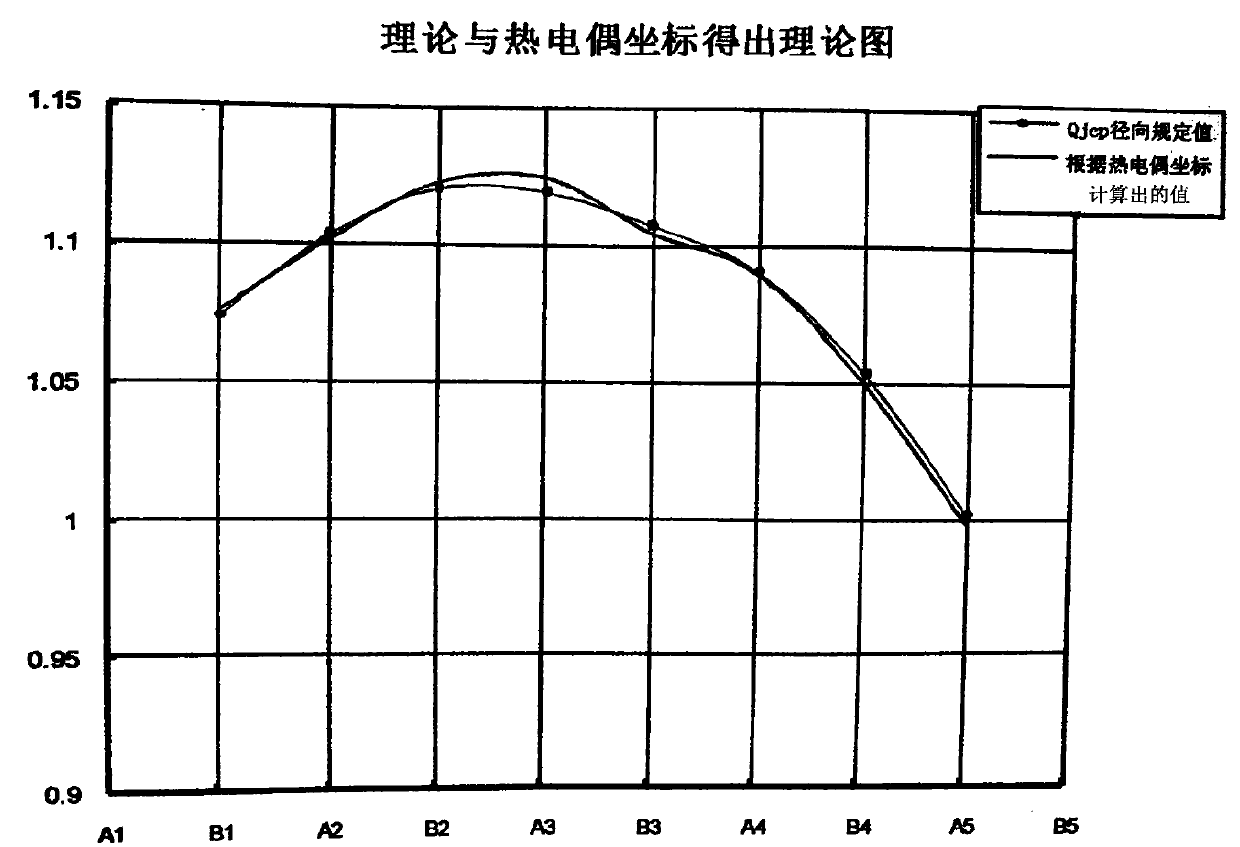

[0048] 3) Data analysis: the screened unqualified data is formed into data image information, and the data is further analyzed to judge the unqualified data;

[0049] 4) Data output: output adjustment plan to guide on-site operation;

[0050] 5) The operator retests according to the adjustment plan, and returns to step 1).

[0051] The basic data in step 1) refers to the basic situa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com