The invention discloses an ABAQUS software-based parametric modeling method for an ultrasonic-assisted small hole drilling grinding wheel

A parametric modeling, ultrasonic-assisted technology, applied in design optimization/simulation, electrical digital data processing, special data processing application, etc. To achieve the effect of reducing dependencies and necessity, reducing geometric modeling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

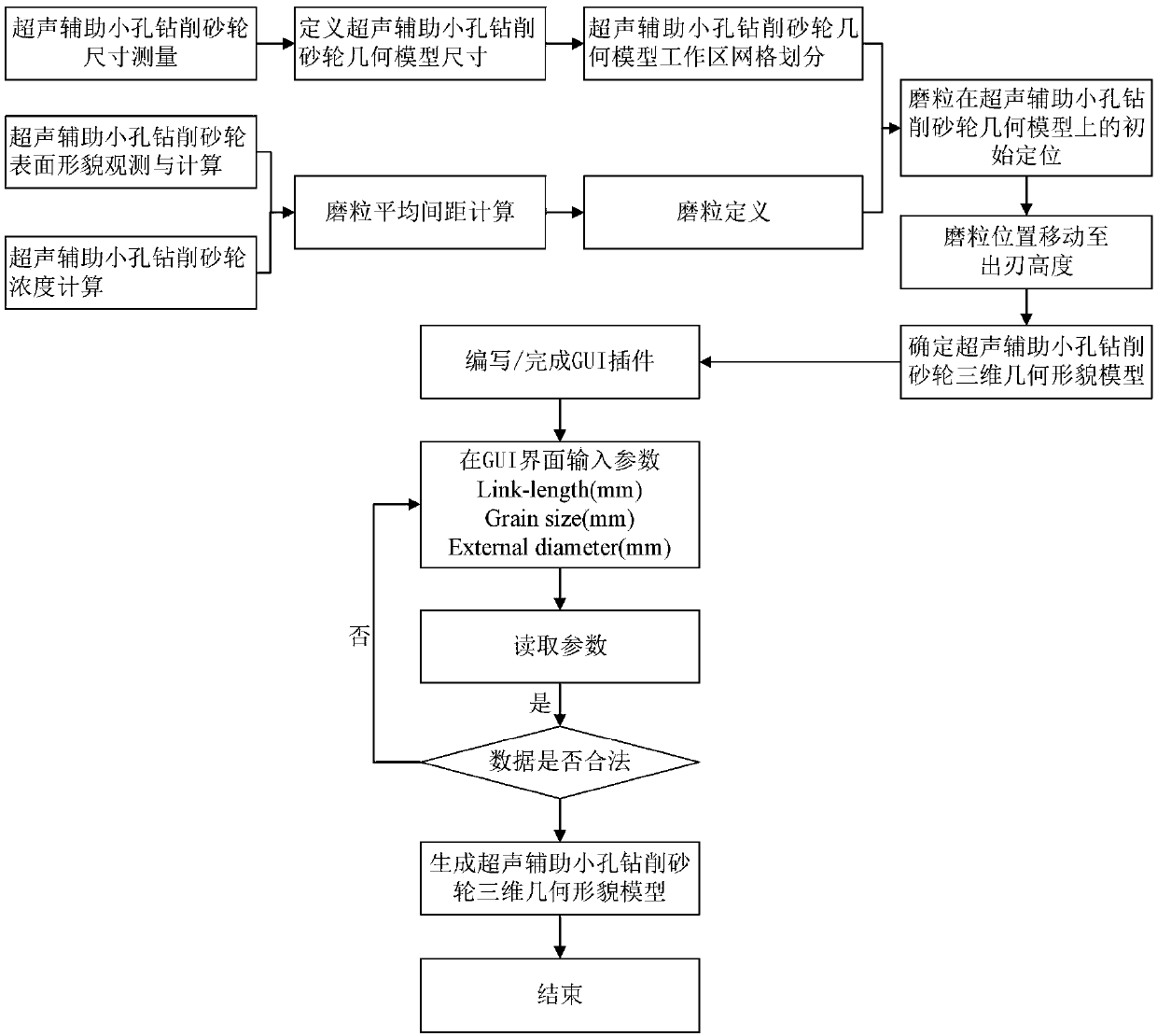

[0032] Such as figure 1 As shown, the ultrasonic-assisted small hole drilling grinding wheel three-dimensional parameterized geometric modeling method based on ABAQUS software of the present invention, the steps are as follows:

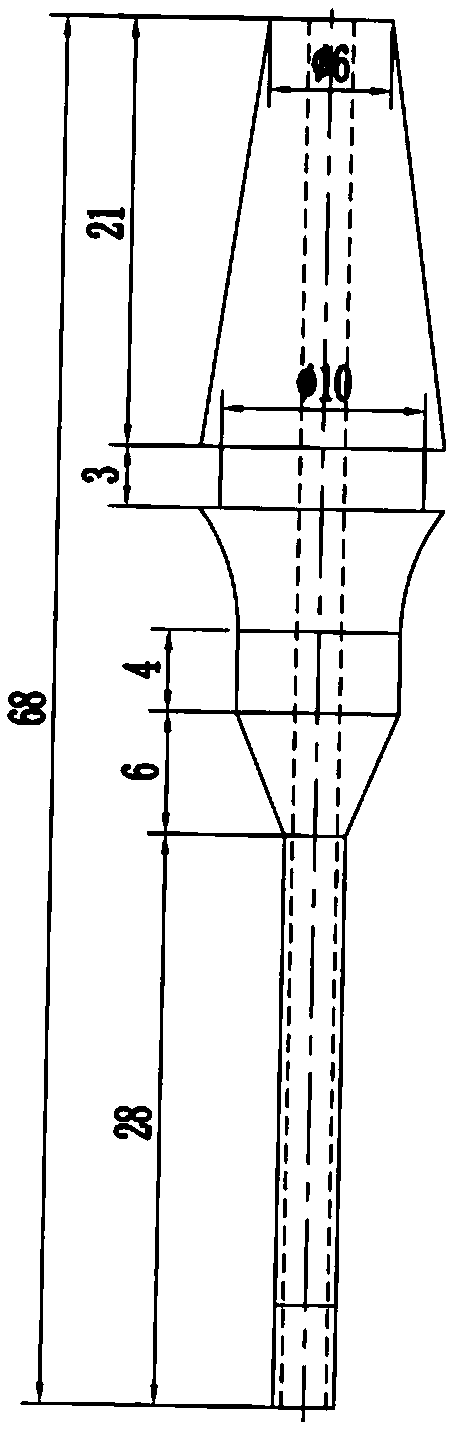

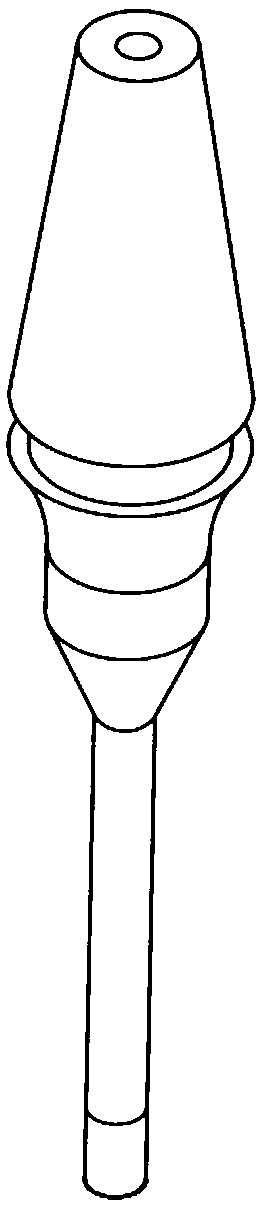

[0033] Step 1: Measure the geometric dimensions of the real ultrasonic-assisted small hole drilling grinding wheel, and define the size of the geometric model of the ultrasonic-assisted small hole drilling grinding wheel. By measuring the geometric dimensions of the real ultrasonic-assisted small hole drilling grinding wheel, the parameters with a central hole diameter of 2.2.mm, a length of the holding end of the grinding wheel end of 24 to 50mm, the length of the working area, the outer diameter of the cutter bar and the size of the abrasive grain can be established. The input 3D geometric model. (as shown in pictur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com