A Modular Internal Hybrid Permanent Magnet Motor Rotor Structure

A technology of hybrid permanent magnet and motor rotor, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit, etc., to improve rotor stress and reliability, improve rotor strength, and reduce cogging torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below through specific embodiments.

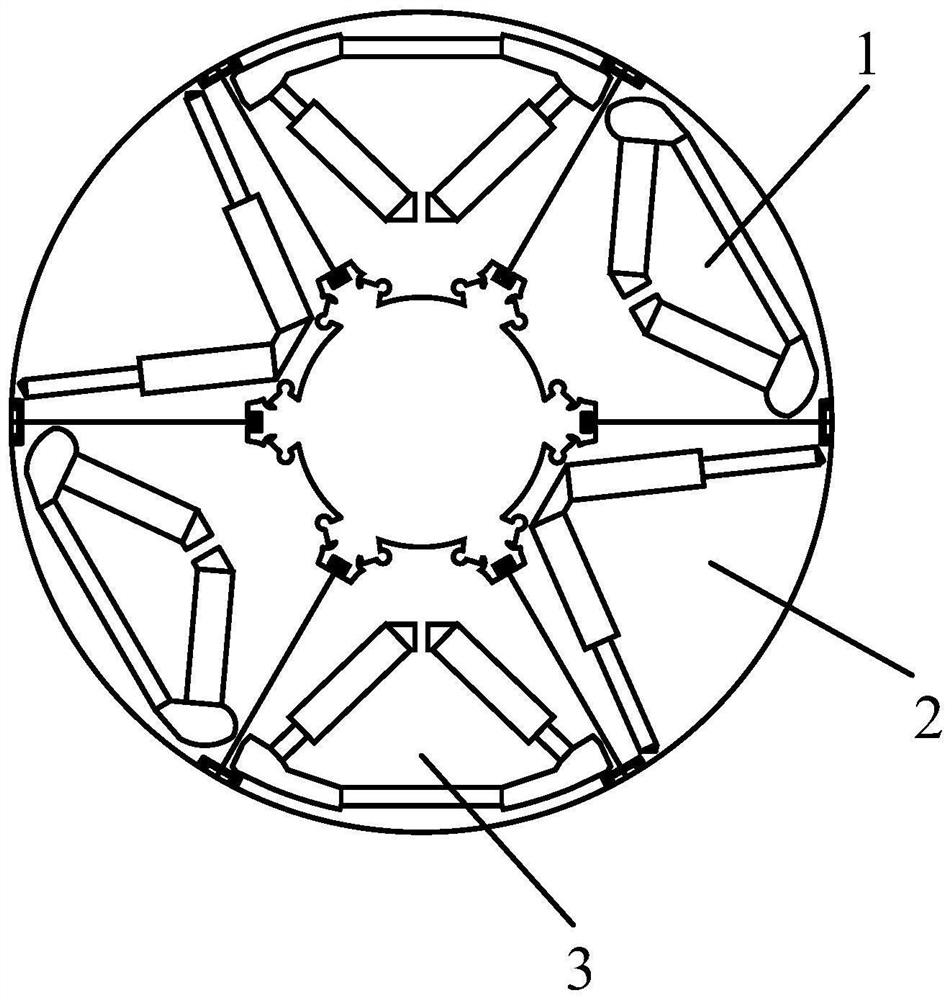

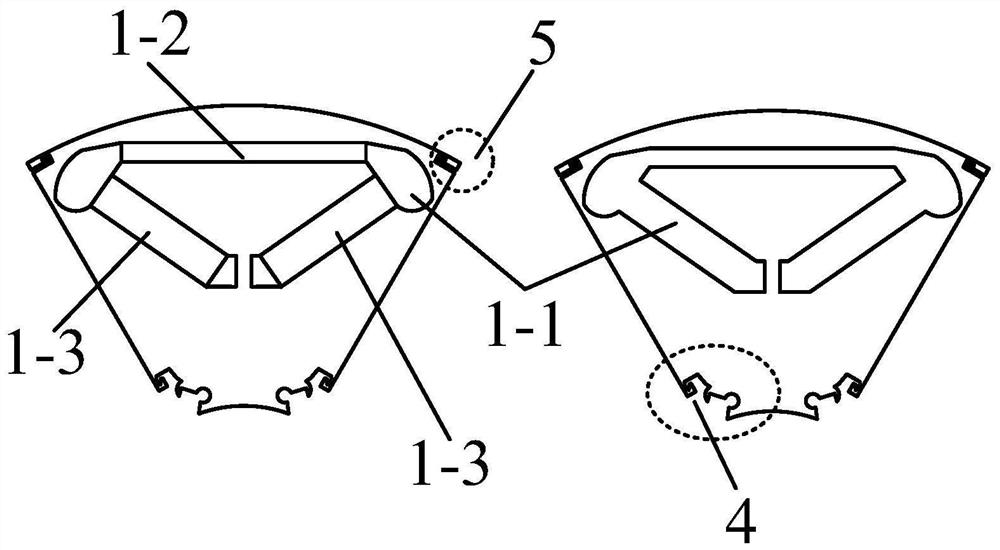

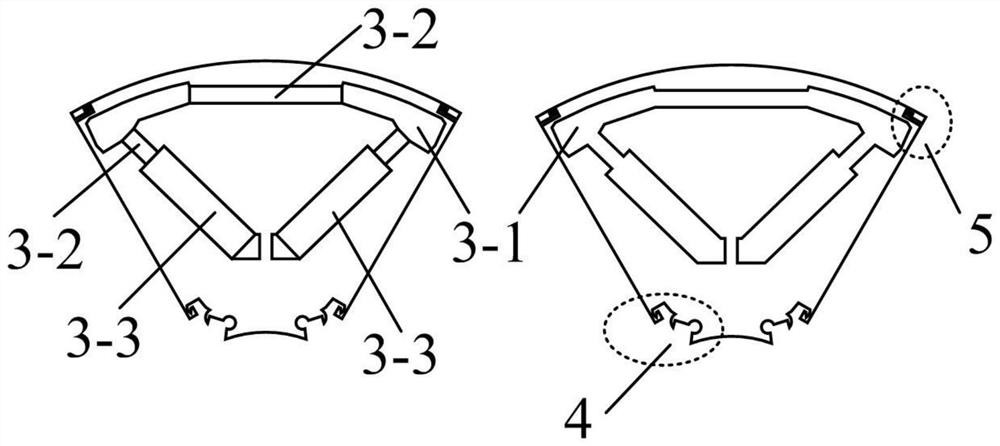

[0039] Such as Figure 1-6 As shown, a modular built-in hybrid permanent magnet motor rotor structure, including 3n fan-shaped rotor modules, n=2,4,6..., and the internal shaft 9-1; 3n rotor modules are composed of three rotor structures Arranged in order, the three rotor modules are provided with permanent magnet slots for embedding permanent magnets. The permanent magnet slots of the three rotor modules are V-shaped slots 2-1 facing the outer circle of the rotor and the first inverted triangular slots. 1-1 and the second inverted triangular groove 3-1, the bottoms of the inverted triangular groove 1 and the inverted triangular groove 2 are all provided with reinforcing ribs.

[0040] The above-mentioned 3n rotor modules are all made of laminated silicon steel sheets, and 3n=2p, where p is the number of pole pairs of the motor; the rotor circumference angle occupied by the 3n rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com