12-micron copper foil full-automatic arranging system

A fully automatic, copper foil technology, applied in electrical components, manufacturing of printed circuit precursors, printed circuit manufacturing, etc., can solve the problems of inability to realize automation of 12um thick copper foil, lack of reasonable structure, customer loss, etc. The effect of automation, convenient and fast maintenance, and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0034] The specific implementation is as follows:

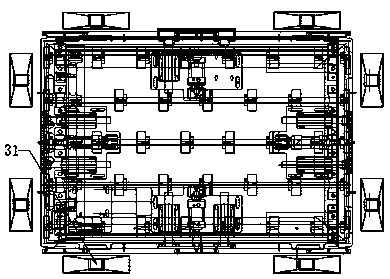

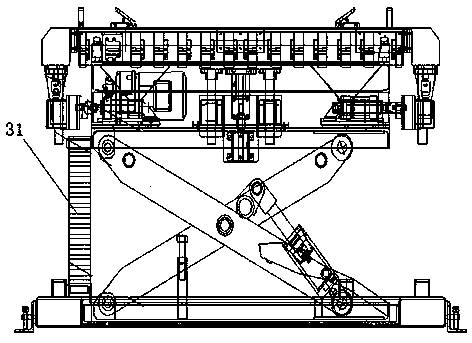

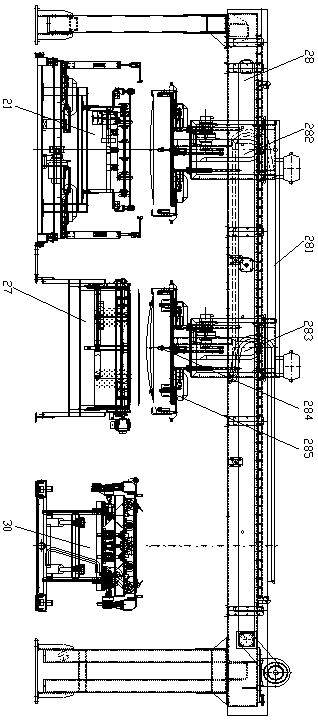

[0035] This equipment is connected to the PCB multi-layer board production line. First, the steel plate conveyor 11 conveys the steel plate through the dust sticking machine 12 to remove dust and transport it to the first lower copper foil conveying and transferring machine 21 to stop at the designated position, and then the lower copper foil is cut. Machine 22 cuts a piece of copper foil and transports it to the second lower copper foil conveying and transferring machine 24, and then the third lower copper foil conveying and transferring machine 25 sucks the copper foil from the second lower copper foil conveying and transferring machine 24 Place it on the first lower copper foil conveying and transferring machine 21. At this time, a steel plate and copper foil are combined into a sandwich shape, and then the sandwich-shaped copper foil and steel plate are picked up by the suction head of the sandwich clamping and transferrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com