Reaction kettle capable of performing rapid and safe reaction

A kind of reaction kettle, fast technology, applied in chemical/physical/physical-chemical fixed reactor, chemical/physical/physical-chemical process, chemical instrument and method, etc., can solve the problem of slow reaction rate, etc. The effect of increasing the heating effect, improving the stirring and heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

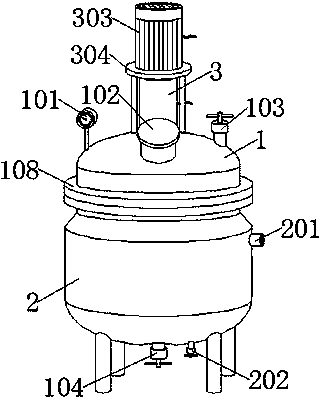

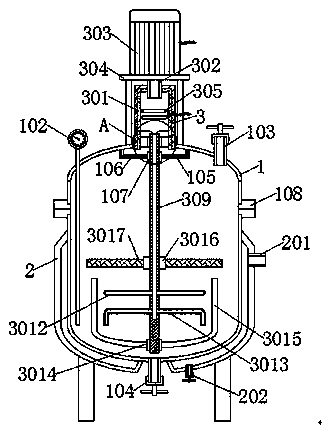

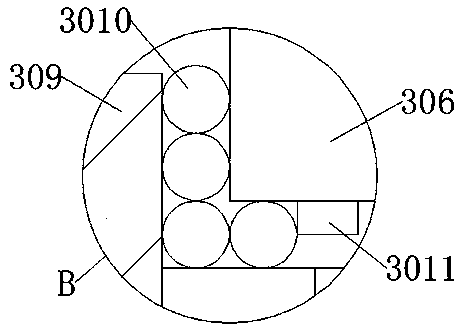

[0026] see Figures 1 to 6 Among them, in the embodiment of the present invention, a reaction kettle with rapid and complete reaction includes a kettle body 1, an air inlet cylinder 3 and a heating jacket 2, the top of the kettle body 1 is embedded with an air inlet cylinder 3, and the bottom of the air inlet cylinder 3 is nested and welded There is a heating jacket 2, the right side of the heating jacket 2 is embedded with a steam inlet pipe 201, and the bottom of the heating jacket 2 is embedded with a water pipe 202; the kettle body 1 includes a thermometer 101, a feeding pipe 102, a feeding pipe 103, and a discharge pipe 104 , separation cover 105, Bakelite cover 106, isolation bearing 107 and flange 108, the top of kettle body 1 is embedded with thermometer 101, the top of kettle body 1 is embedded and welded with feeding pipe 102, and the top of kettle body 1 is embedded and welded with feed Pipe 103, the bottom of the kettle body 1 is embedded with a discharge pipe 104,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com