Rapid replacement method for slewing bearing of large continuous casting ladle turret

A technology of slewing bearing and replacement method, applied in casting equipment, casting melt container, metal processing equipment, etc., can solve the problems of construction technology consuming a lot of manpower and material resources, difficult to meet the needs of fast-paced, high-intensity production, and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

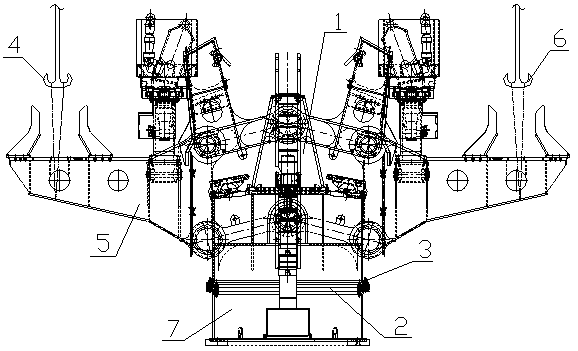

[0022] Example figure 1 and figure 2 As shown, the rapid replacement method of the slewing bearing of the large continuous casting ladle turret of the present invention comprises the following steps:

[0023] Step 1. Fabricate and install the support platform of the turntable on one side of the ladle turntable, and set the support beam of the cross arm of the turntable and the lifting support column for fixing the cross arm of the turntable on the support platform;

[0024] Step 2. Remove the hydraulic slip ring and corresponding oil pipe, electrical slip ring and corresponding electrical circuit in the ladle turret respectively;

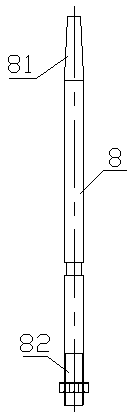

[0025] Step 3: Disassemble the connecting bolt 3 between the main body 1 of the ladle turret and the slewing bearing 2, and reserve a connecting bolt at every 90-degree position, and pour the molten steel into the steel straddle crane hook 4 to connect the cross arm 5 of the ladle turret through a steel wire rope. side, the molten steel receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com