Hard film layer reparation device of fingerprint sensor

A fingerprint sensor and hard film technology, which is applied in the field of hard film repair devices, can solve the problems of high cost loss, easy adhesion of external oil or dust, and influence on the surface cleanliness and cleanliness of fingerprint identification keys, etc., to achieve The effect of smooth surface, low cost and simple repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

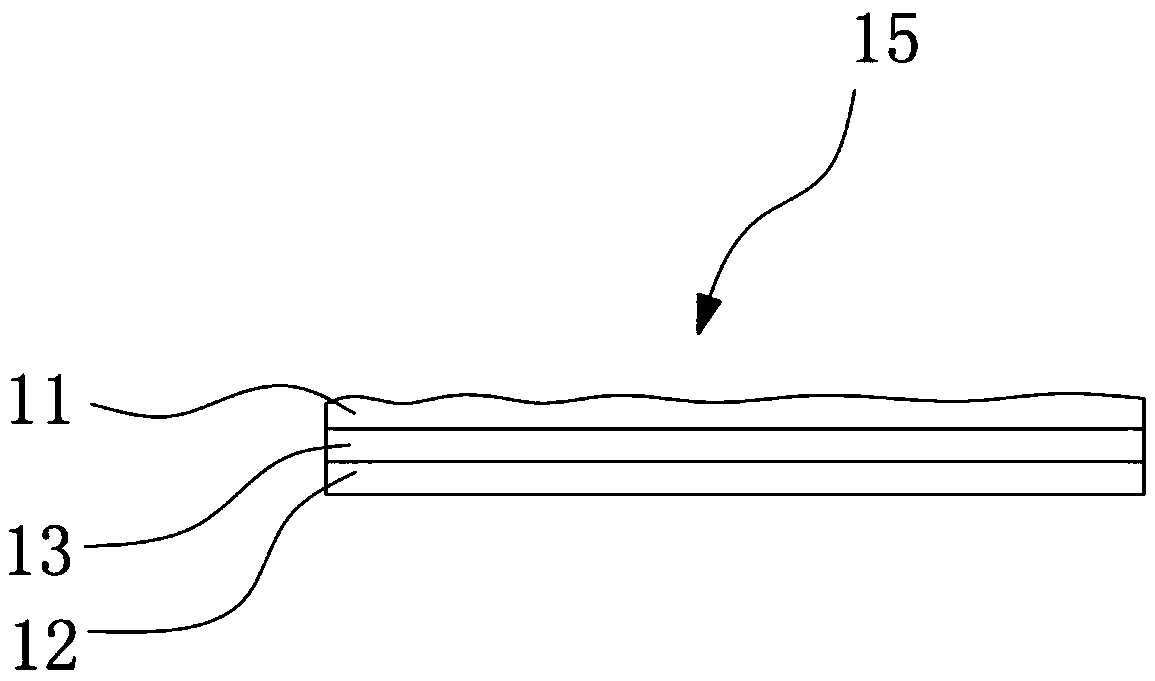

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

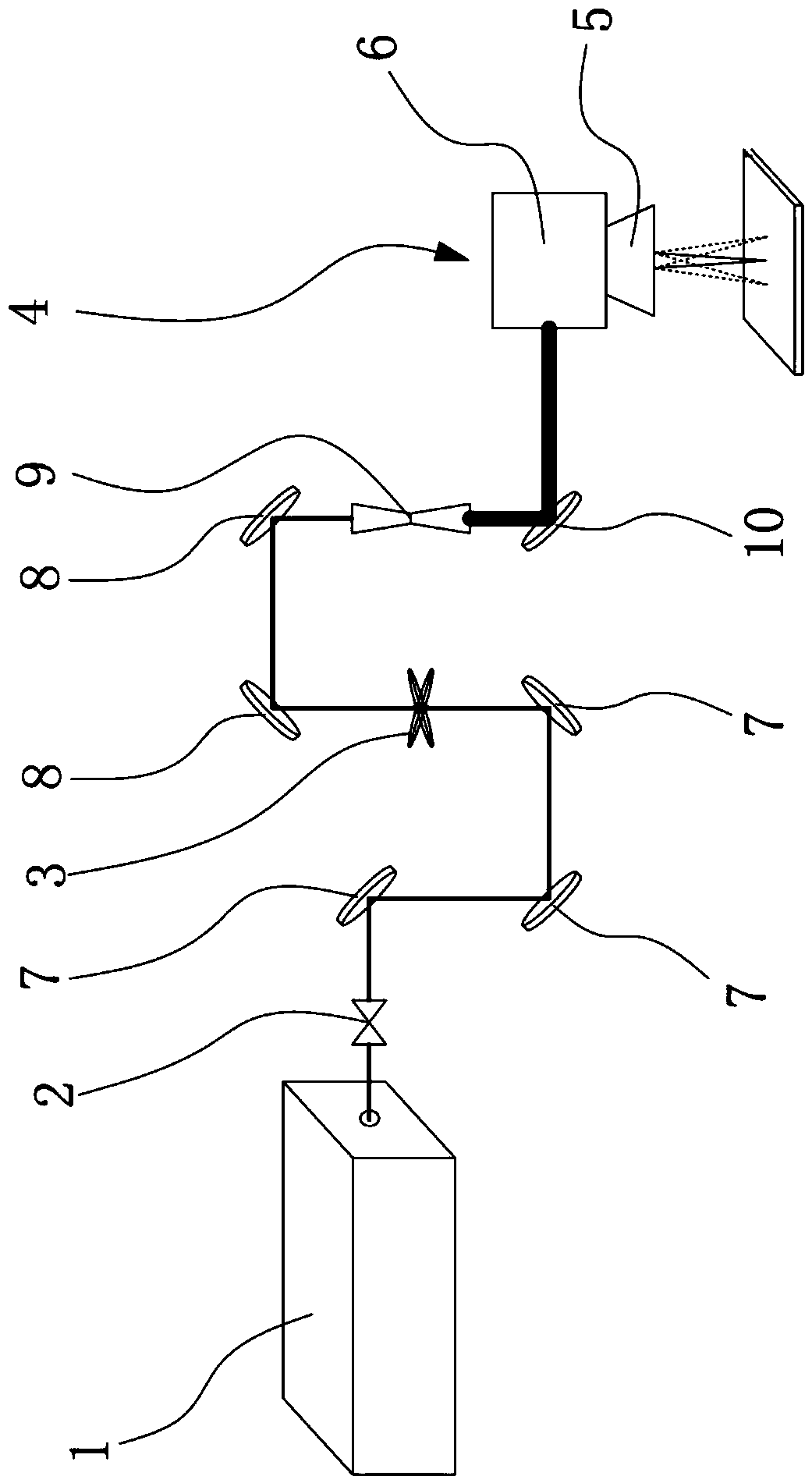

[0024] refer to figure 1 , the present embodiment is a device for repairing the hard film layer of a fingerprint sensor, including a laser emitter 1, an attenuator 2, a polarizer 3, a beam expander 9 and an etcher 4 arranged in sequence, and the polarizer 3 and the attenuator 2 At least one first reflector 7 is arranged between them, at least one second reflector 8 is arranged between the beam expander 9 and the polarizer 3, at least one third reflector is arranged between the etcher 4 and the beam expander 9 10. The first reflector 7, the second reflector 8 and the third reflector 10 are all used to collimate the laser beam.

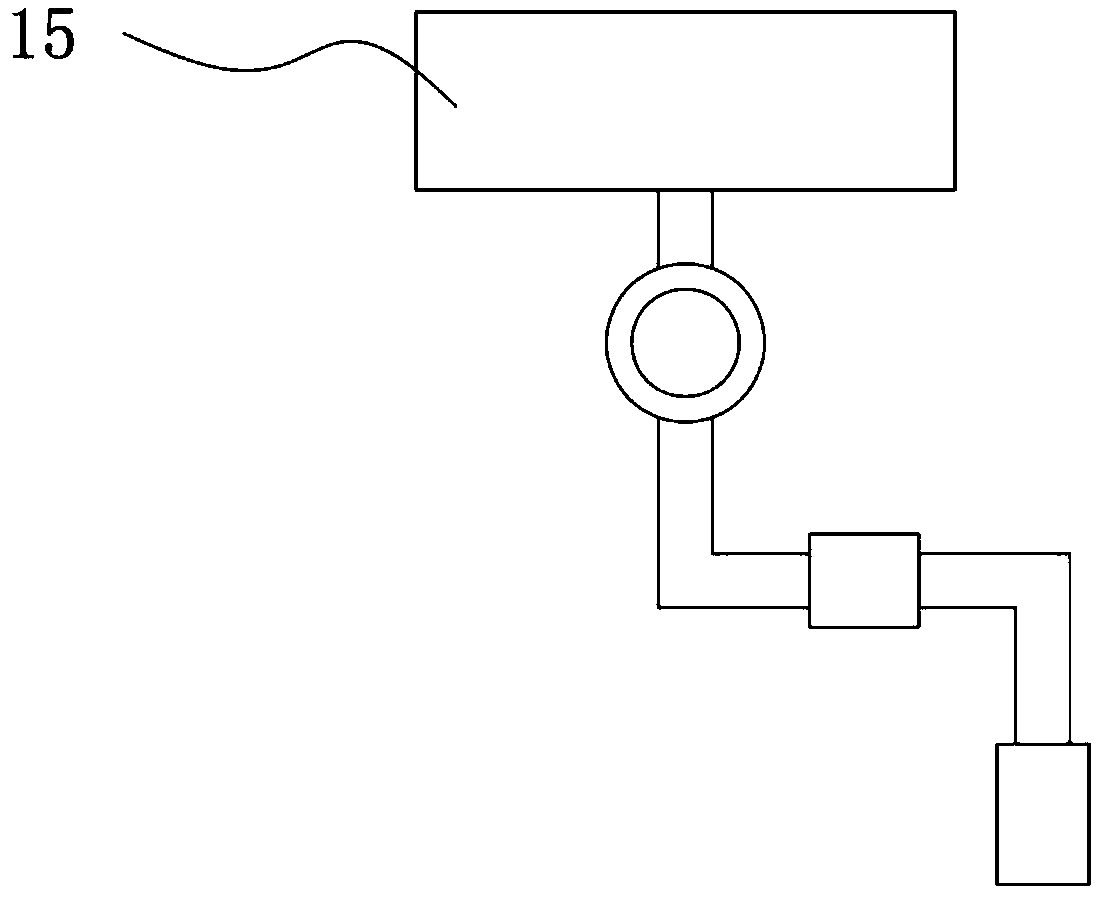

[0025] Further, the etcher 4 includes a field mirror 5, an etching mirror, a motor, and a scan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap