Full-automatic rice cake printing and cutting-off device

A cutting device, fully automatic technology, applied in metal processing, food forming, food science and other directions, can solve the problems of increased production costs, different sizes of rice cakes, manual errors, etc., to achieve a high degree of automation, good processing effect, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

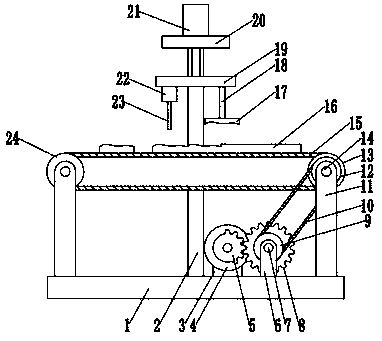

[0023] see figure 1 , a fully automatic rice cake printing and cutting device, comprising a base 1 and a rice cake strip 16, the center of the top of the base 1 is fixedly connected with a support rod 2, the top of the support rod 2 is fixedly connected to a placement plate 20, and the top of the placement plate 20 is fixedly connected to a cylinder 21, The piston rod of the cylinder 21 is slidably connected to the placement plate 20, the piston rod of the cylinder 21 is fixedly connected to the fixed plate 19, the fixed plate 19 is slidably connected to the outside of the support rod 2, the left side of the fixed plate 19 is fixedly connected to the knife seat 22, and the knife seat 22 A cutting knife 23 is installed inside, a connecting rod 18 is fixedly connected to the right side of the bottom of the fixing plate 19 , and the top of the connecting rod 18 is fixedly connected to the printing mold 17 .

[0024] The top of the base 1 is fixedly connected to the motor base 3, ...

Embodiment 2

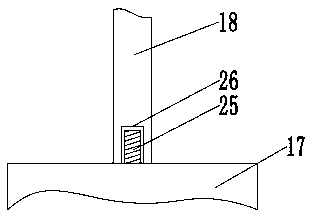

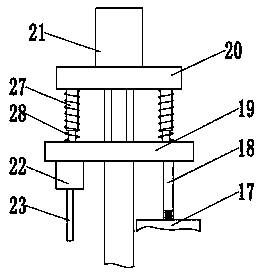

[0026] see figure 2 with image 3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the bottom of the connecting rod 18 is provided with a screw hole 26, the top of the printing mold 17 is fixedly connected to the threaded post 25, and the threaded post 25 is threaded to the threaded hole 26. It is convenient for users to replace the printing mold 17, so as to print different styles of printing, which increases the flexibility of the device and reduces the cost. The left and right sides of the bottom of the placement plate 20 are fixedly connected to the telescopic rod 27, and the bottom of the telescopic rod 27 is fixed Connected to the fixed plate 19, the outer side of the telescopic rod 27 is covered with a spring 28, the spring 28 is fixedly connected between the placement plate 20 and the fixed plate 19, when the piston rod of the cylinder 21 is extended, the cutting knife 23 and the printing mold 17 are driven downward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com