Method for conducting linkage transportation on ship master segment through flat cars

A technology of flatbed truck and general section, which is applied in the field of flatbed truck linkage transport ship general section, which can solve the problems of non-transportation, etc., and achieve the effects of improving production efficiency, alleviating site tension, and improving ship construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

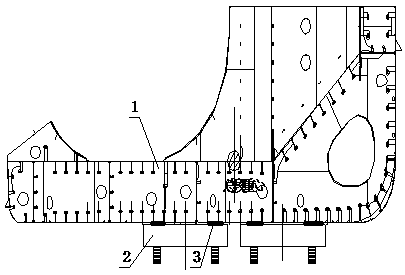

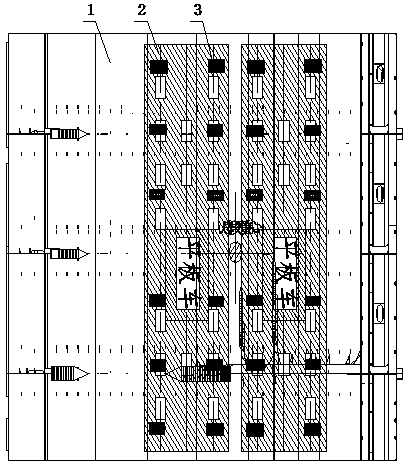

[0026] like figure 1 and figure 2 As shown, referring to the schematic diagram of the method of parallel transporting the general section of the ship (excluding the mast) by flatbed trucks, the method of this embodiment mainly includes the following detailed steps:

[0027] The first step is to drive two flatbed trucks 2 to the site area of the general section, and park them side by side in the open space, one on the left and one on the right. The distance between the two vehicles is determined according to the overall size of the hull section 1, and the debugging equipment is linked.

[0028] In the second step, according to the structural characteristics of the general hull section 1, the skids 3 are pre-placed at the corresponding positions of the flatbed truck 2, and the skids are generally 100mm in height.

[0029] In the third step, the general section 1 of the hull is hoisted onto the flatbed truck 2, and whether each skid 3 is compacted is checked to ensure that th...

Embodiment 2

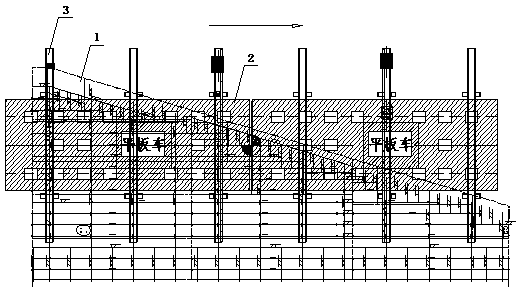

[0032] like image 3 and Figure 4 As shown, the schematic diagram of the method for the flatbed truck to transport the general section of the ship (including the gantry) in series, the method of the present invention mainly includes the following detailed steps:

[0033] The first step is to drive two flatbed trucks 2 to the site area of the general group of the general section, and park them in the open space in the order of one before the other. The distance between the two vehicles is determined according to the overall size of the hull general section 1, and the debugging equipment is linked.

[0034] In the second step, according to the structural characteristics of the hull general section 1, the gantry resting pier 4 is placed in advance on the corresponding position of the flatbed truck 2, and then the skid 3 and the auxiliary support 5 are placed on the mast pier. The height of the skid 3 is generally 100mm, the position of the auxiliary support 5 is determined ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com