Manufacturing optimization method for multi-curvature special-shaped curved surface steel structure

A technology of special-shaped surface and optimization method, which is applied in the direction of instrument, geometric CAD, calculation, etc., can solve the problems of complex, chaotic, and difficult to fully meet the design requirements of the multi-curvature special-shaped surface production process, so as to improve the construction of multi-curvature special-shaped steel structures. Production process, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

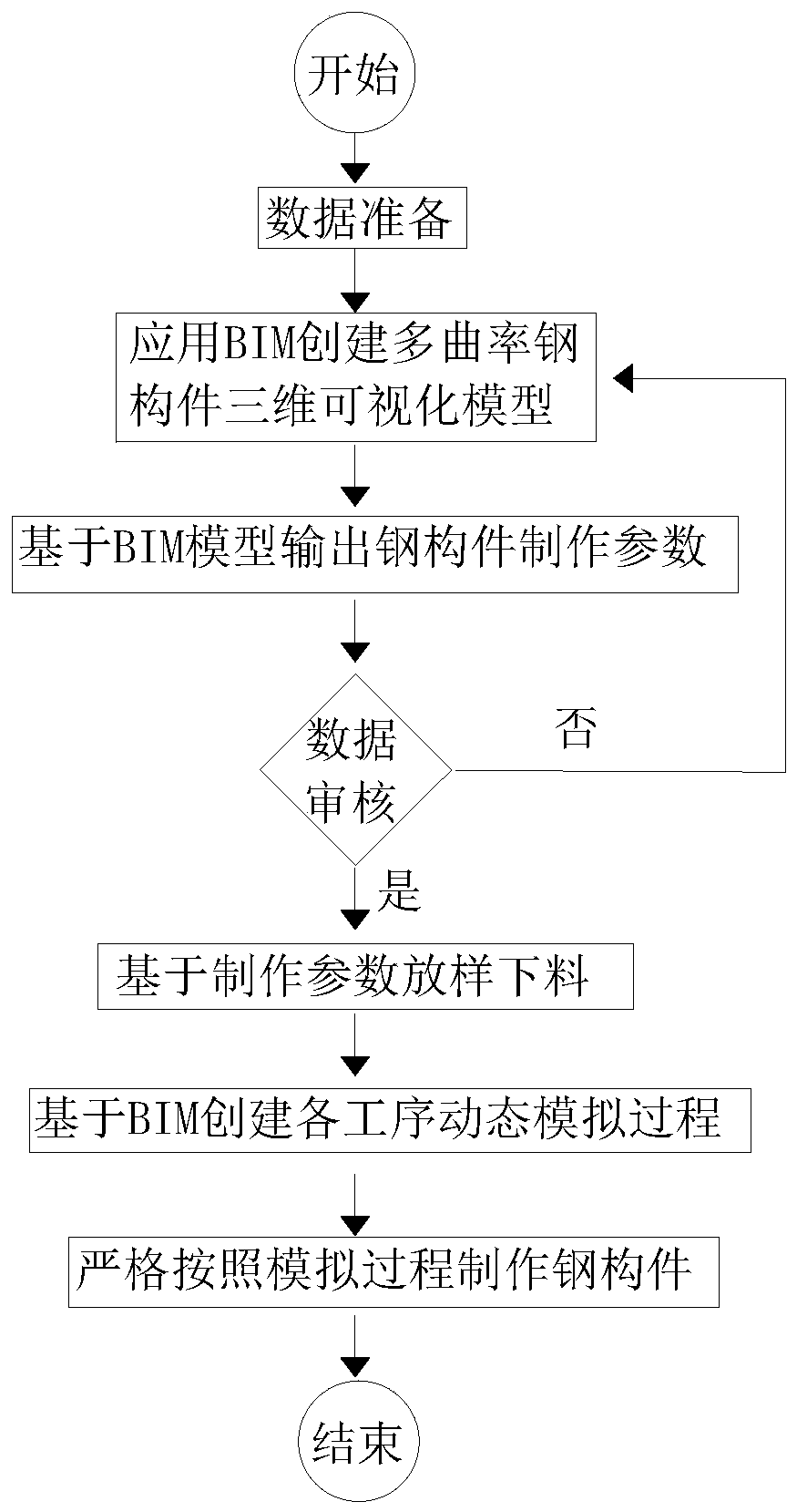

[0023] Such as figure 1 Shown: An optimization method for the manufacture of a multi-curvature special-shaped curved surface steel structure, including the following steps:

[0024] Step 1. Apply BIM to create a 3D visualization model of steel components;

[0025] Step 2. Output and review steel member fabrication parameters based on the BIM model;

[0026] Step 3. Make lofting and blanking based on the approved parameters;

[0027] Step 4. Apply BIM to create a dynamic simulation process of paneling, profile bending, cutting, assembly, welding, hole making, assembly, riveting spare parts blanking, welding inspection, rust prevention, and acceptance;

[0028] Step 5. Strictly follow the simulation process for steel structure fabrication.

[0029] Among them: the ratio of the model to the entity described in step 1 is 1:1, including a single steel component model and a multi-curvature special-shaped surface steel structure overall model. The model includes component numbers,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com