Construction method of hydraulic drill excavation of catenary post foundation pit

A construction method and catenary technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of high labor cost and fuel cost, high equipment input cost, environmental pollution on the surrounding side, etc. The effect of low equipment cost and excavation quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

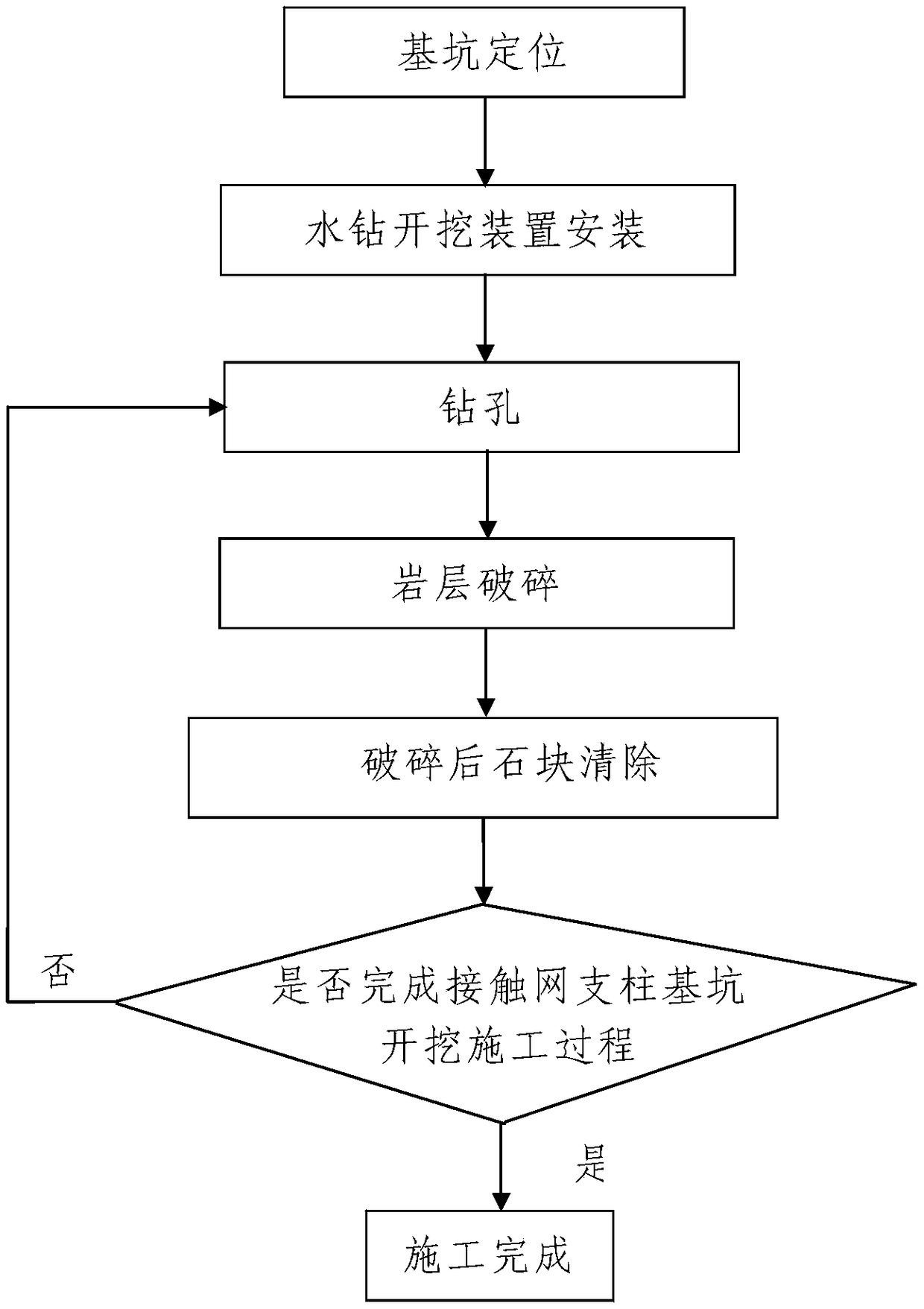

[0062] Such as figure 1 A catenary pillar foundation pit water drilling excavation construction method shown includes the following steps:

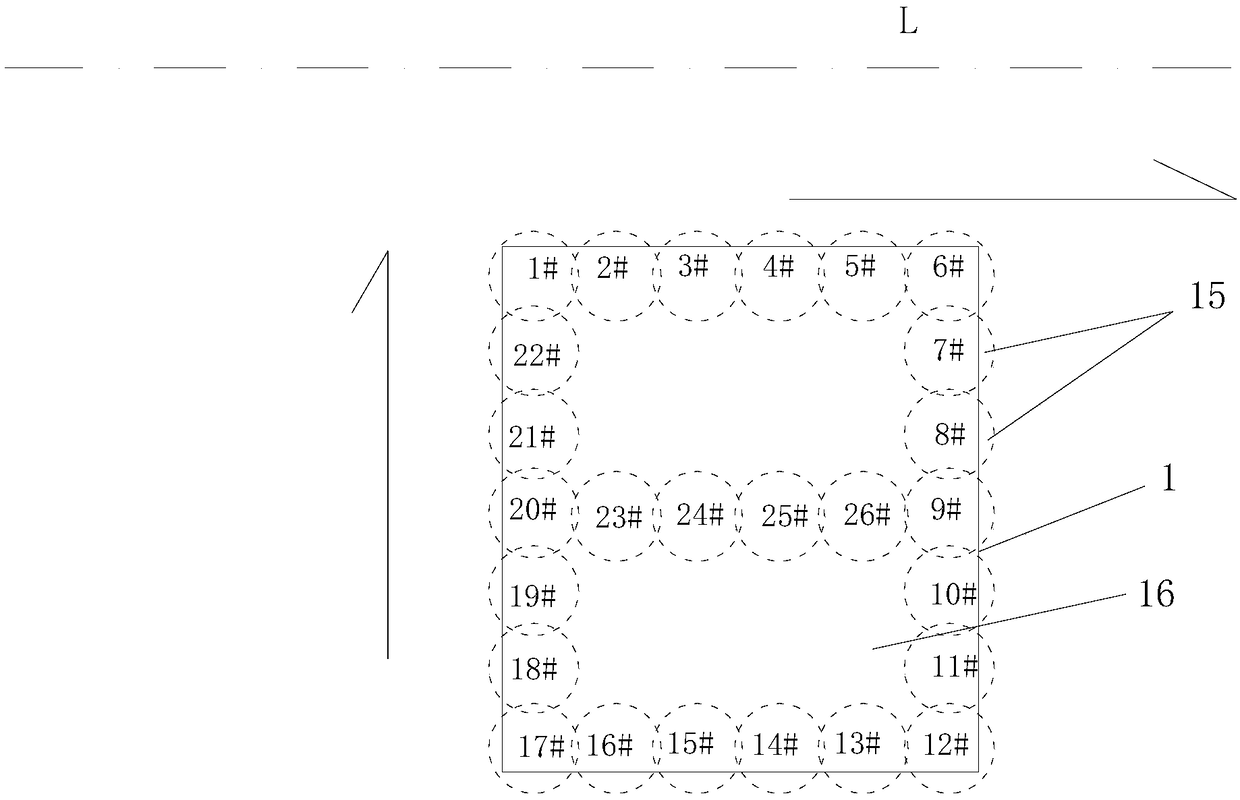

[0063] Step 1. Foundation pit positioning: measure and set out the layout position of the excavated catenary pillar foundation pit 1, see image 3 ;

[0064] The excavated catenary pillar foundation pit 1 is a vertical foundation pit excavated and formed in the rock 16 from top to bottom. The catenary pillar foundation pit 1 is for the catenary pillar to be installed and located The cube pit on one side of the catenary, the area where the catenary pillar foundation pit 1 is located in the rock 16 is the area to be excavated;

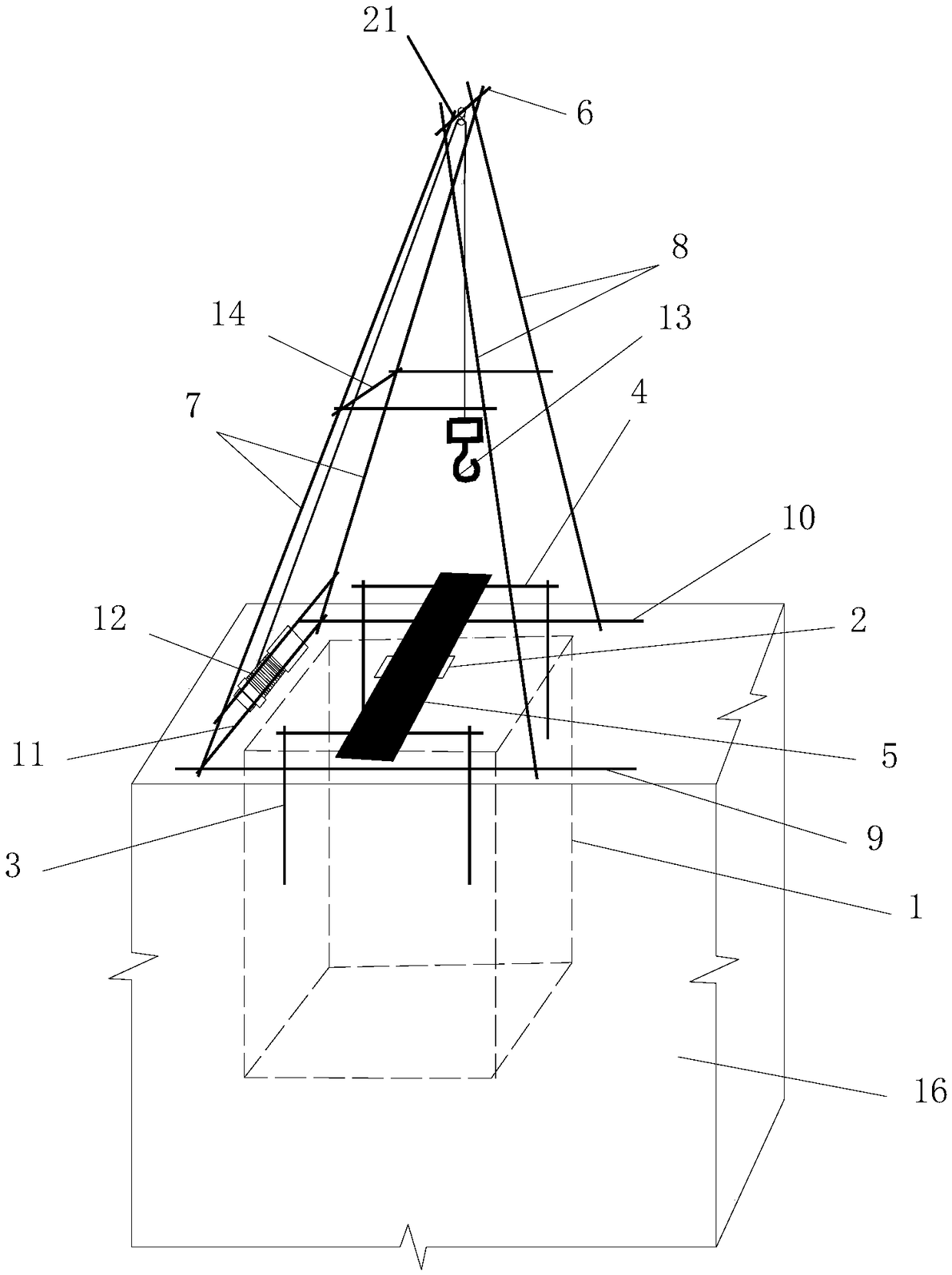

[0065] Step 2, installation of the water drilling excavation device: according to the measuring and setting-out results in step 1, install the water drilling excavation device for excavating the catenary pillar foundation pit 1;

[0066] Such as figure 2 As shown, the water drill excavation device includes a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com