Intelligent slime water processing method and device

A treatment method, slime water technology, applied in water/sludge/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low comprehensive efficiency and low degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

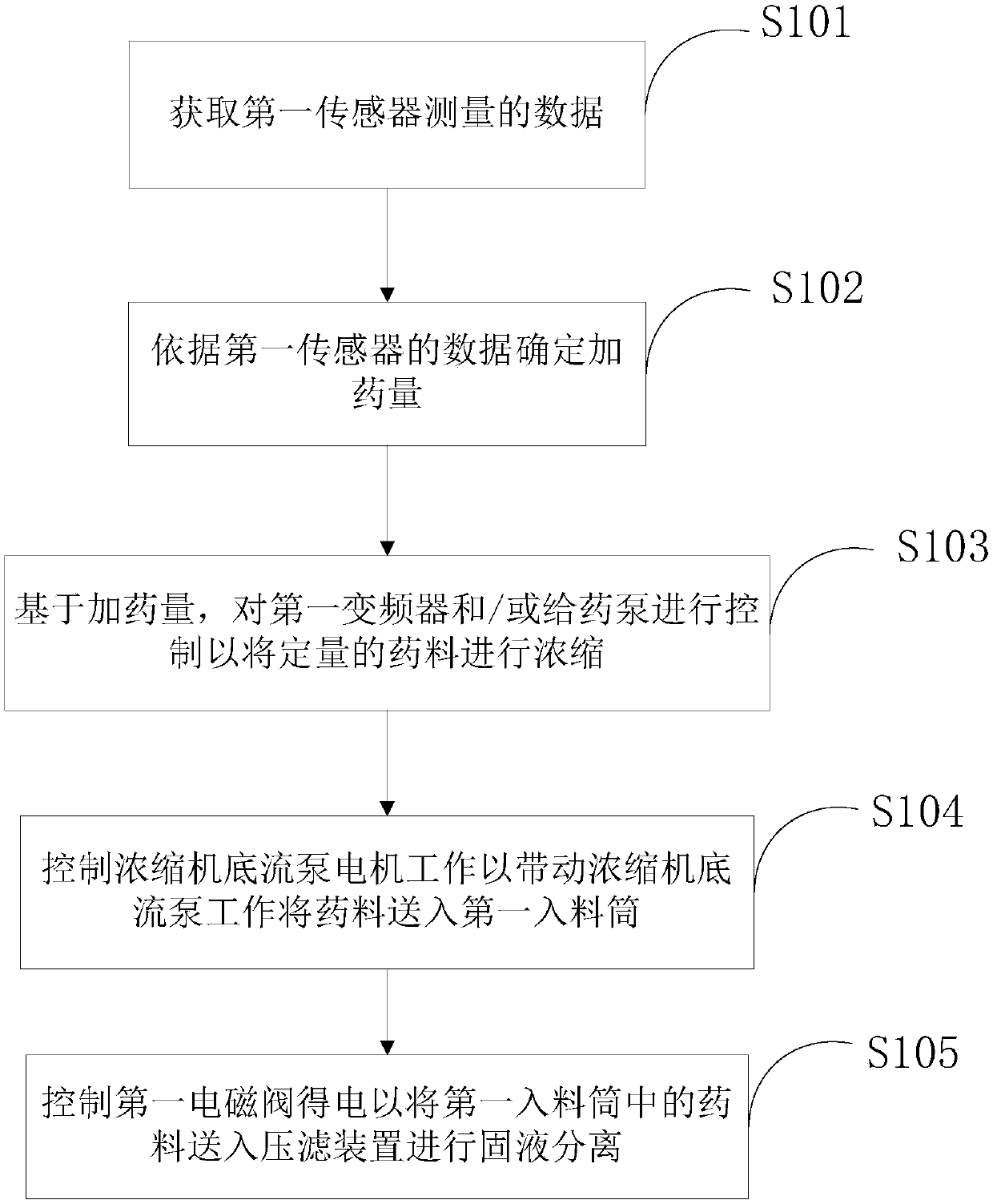

[0079] like figure 1 As shown, the embodiment of the present invention provides a kind of intelligent slime water treatment method, comprises the following steps:

[0080] S101: Obtain data measured by the first sensor;

[0081] Execute S101: After the step of acquiring the data measured by the first sensor, the executed step is S102: Determine the dosing amount according to the data of the first sensor;

[0082] After performing the step of S102: determining the dosage according to the data of the first sensor, the executed step is S103: based on the dosage, control the first frequency converter and / or the drug delivery pump to concentrate the quantitative dosage ;

[0083] Specifically, the controller controls the dosing amount by controlling the gain and loss time of the first electromagnetic valve and / or the output frequency of the first frequency converter. Concentration meter, thickener underflow flowmeter, thickener underflow concentration meter, thickener overflow c...

Embodiment 2

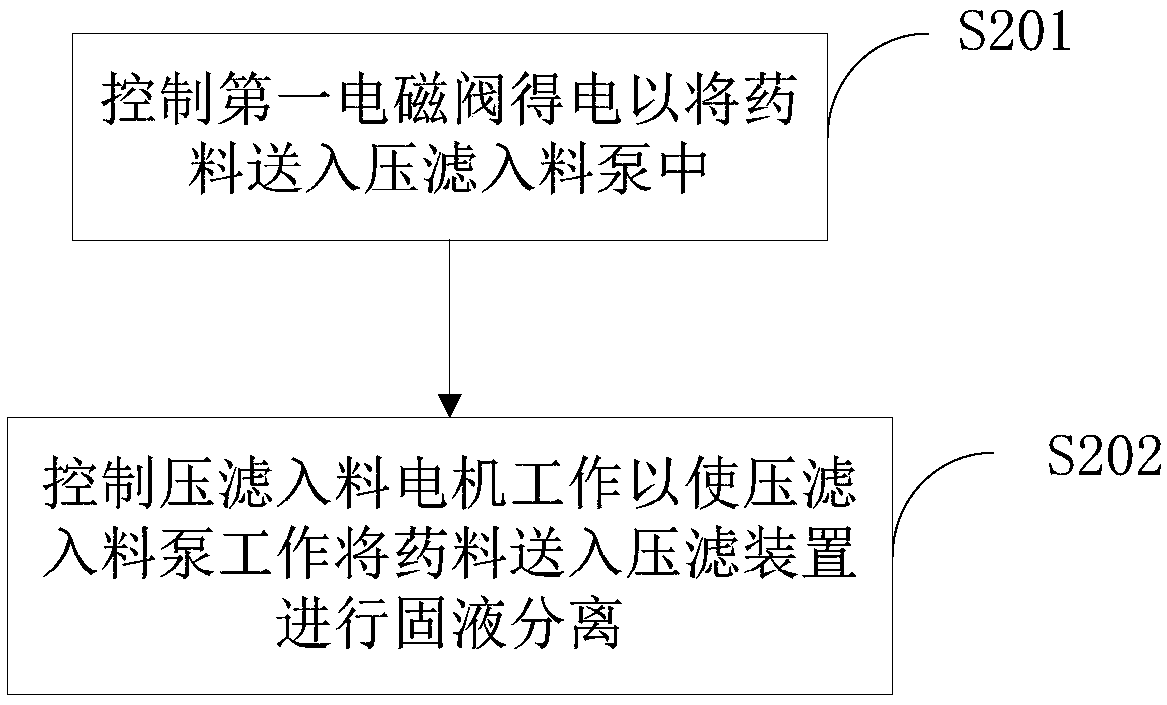

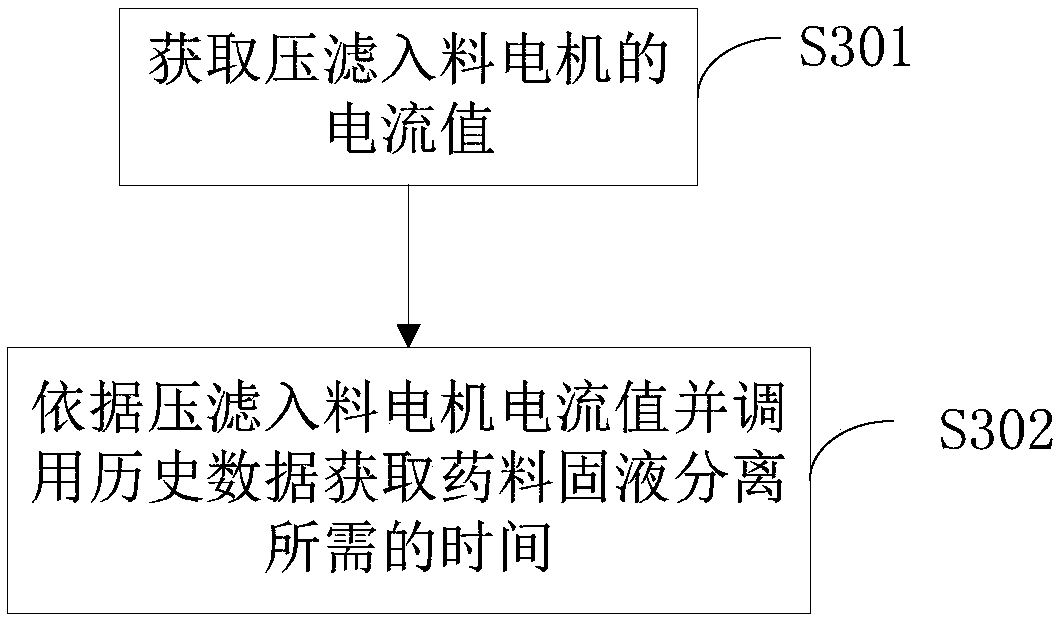

[0115] like image 3 As shown, embodiment two on the basis of embodiment one based on embodiment one to S104: control the second solenoid valve to be energized to send the medicine in the first charging cylinder into the filter press device: the step of solid-liquid separation made public, including:

[0116] S301: Obtain the current value of the filter press feeding motor;

[0117] S302: Obtain the time required for the solid-liquid separation of the medicine according to the current value of the feed motor of the press filter and call the historical data;

[0118] When the time required for the solid-liquid separation is reached, the above-mentioned step of S201: controlling the first electromagnetic valve to be energized to send the medicinal material into the press-filtered material pump is performed.

[0119] like Figure 4 As shown, in order to feed the filter press device, in other embodiments provided by the present invention, the above-mentioned intelligent slime w...

Embodiment 3

[0124] Embodiment three provides a kind of intelligent slime water treatment device, such as Figure 5 As shown, the above-mentioned intelligent coal slime water treatment device includes:

[0125] an information acquisition module, configured to acquire data measured by the first sensor;

[0126] The dosage determination module is used to determine the dosage according to the data of the first sensor

[0127] The dosing volume control module is used to control the first frequency converter and / or the dosing pump based on the dosing volume so as to concentrate the quantitative medicine;

[0128] The underflow pump control module is used to control the operation of the underflow pump motor of the concentrator to drive the underflow pump of the concentrator to send the medicine into the first feeding barrel;

[0129] The first solenoid valve control module is used to control the first solenoid valve to be energized so as to send the medicinal material in the first feeding barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com