High-blackness glass melting furnace crown without attenuating blackness

A glass melting furnace, high blackness technology, applied in the field of glass melting furnace, can solve the problem of attenuation and failure of black body coating, and achieve the effect of excellent furnace enclosure extension, improved melting capacity, and increased heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

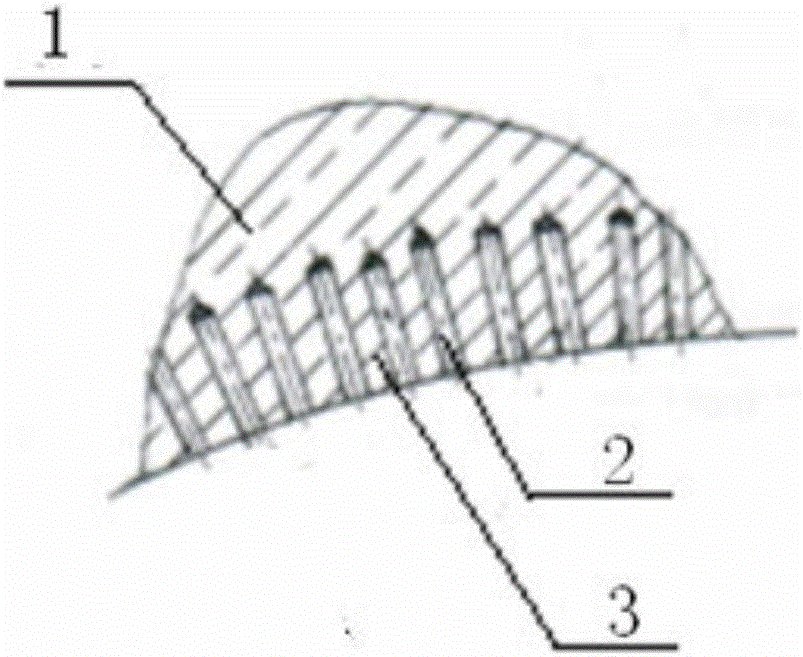

[0031] A large wall 1 of a glass melting furnace with high blackness and non-attenuating blackness, comprising a fire-facing lining of the main body of the large wall, characterized in that a black body element 2 is arranged in the shallow surface layer 3 of the fire-facing lining , so that the glass melting furnace can absorb and emit the radiant energy in the furnace with an absorptivity and emissivity of ≮0.98, respectively. The blackbody element is an inner cylinder or an inner prism with an opening, and the opening end faces the melting pool of the glass melting furnace. The arrangement density of the black body elements is γ=120~400 pieces / m 2 . The section diameter of the blackbody element is Φ14mm˜Φ20mm, and the depth dimension of the blackbody element is H=60mm˜120mm.

Embodiment 2

[0033] A large wall for a glass melting furnace with high blackness and non-attenuating blackness as described in Example 1, the difference is that the material of the black body element is the same as that of the main body of the large wall.

Embodiment 3

[0035] A glass melting furnace with high blackness and no blackness attenuation as described in Example 1. The difference is that the thickness δ=60mm-120mm shallow surface layer inside the furnace lining on the fire facing side of the said Dalong , set with tens of thousands of blackbody elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com