Pattern velvet fabric and manufacturing method

A manufacturing method and technology of velvet fabrics, which are applied in fabrics, textiles, papermaking, textiles, etc., and can solve problems such as no public reports on the technology of velvet fabrics with patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Technical scheme of the present invention is as follows:

[0014] A method for manufacturing patterned velvet fabric, which uses polyester-cotton blended snowflake yarn as raw material, weaves it on a double rapier loom, and then dyes and finishes it, wherein:

[0015] The specification of the polyester-cotton blended snowflake yarn is 32S / 2 polyester-cotton snowflake yarn. The polyester fiber and cotton fiber are respectively combed to make slivers, and then the polyester fiber slivers and cotton fiber slivers are paralleled. Draw frame, and then go to roving and spun yarn for spinning;

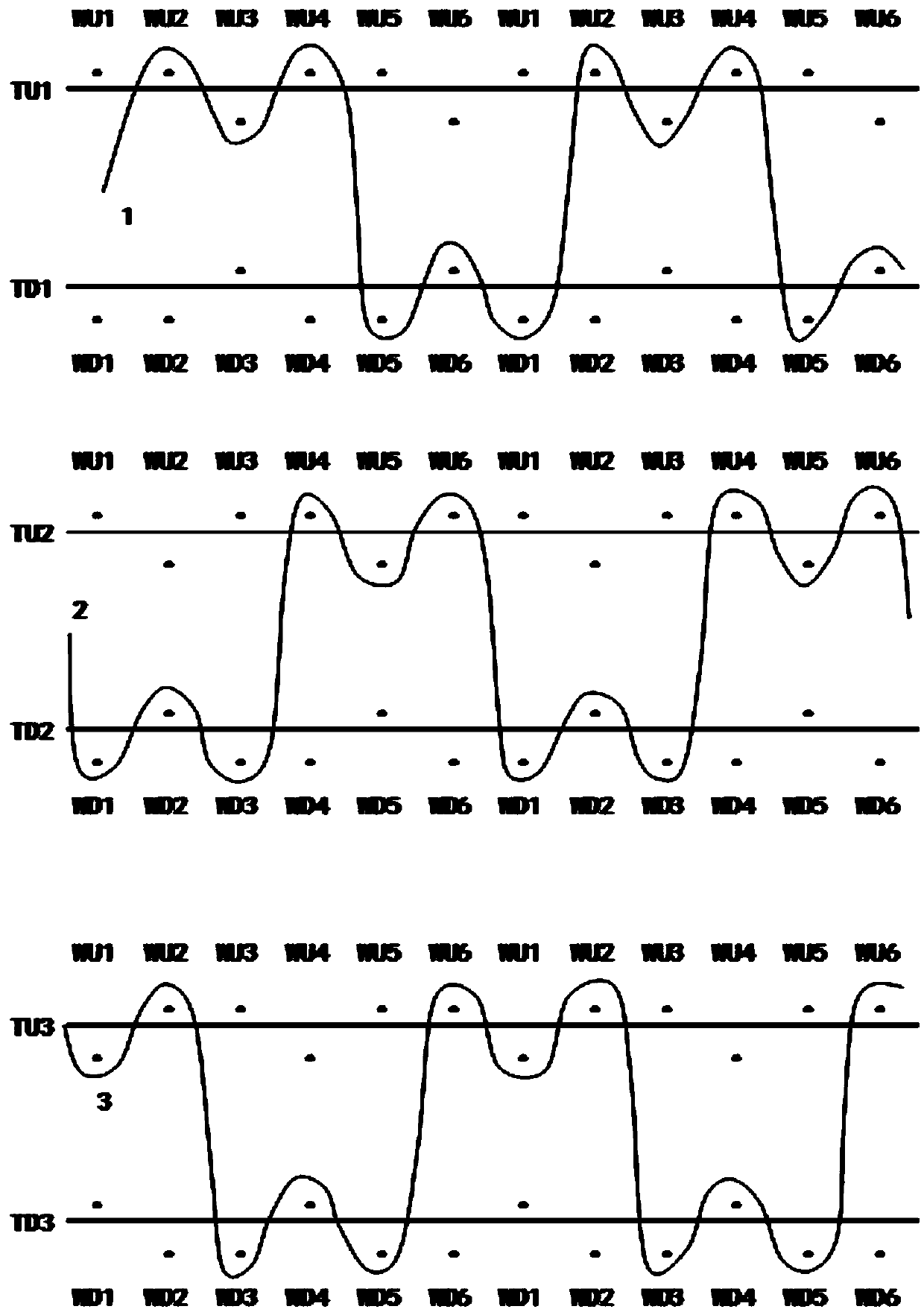

[0016] The weaving adopts the weaving method of dividing warp yarns into ground warp and velvet warp. The ground warp adopts two ground warp heads, and the ground warp yarn is divided into upper ground warp and lower ground warp after passing through the splitting rod, and the weft yarn is divided into The upper layer weft yarn and the lower layer weft yarn, the upper ground warp and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com